Abstract

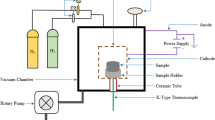

Active screen plasma nitriding is a newly developed technique utilized to enhance low alloy steel's surface property by placing them inside a steel case and supplying biased voltage to the cage. In this work, low alloy steel EN24 samples are plasma nitrided using active screen at different process parameters to improve its surface properties. The EN24 samples are treated at 500˚C and 550˚C treatment temperature for 2 h, 4 h and 6 h with gas flow ratio of \({H}_{2}/{N}_{2}=4:1\).The active screen plasma-nitrided samples are analyzed with various analytical techniques such as SEM, XRD, EDS, microhardness test, weight loss technique and potentiodynamic polarization test. From the SEM analysis, it is found that the compound layers vary from 12.680 to 22.025 µm. Further, the SEM analysis also reveals the formation of transformed austenite phases with increasing temperature and treatment time. Phase identification is performed on treated samples by XRD, which reveals the formation of \(\varepsilon ({Fe}_{2-3}N)\) and \(\upgamma ({Fe}_{4}N)\) on the surface of the samples. Using the microhardness test, it is found that the hardness value of treated samples has increased by 3.5 times (approx.) from the base material. From the weight loss technique, the minimum weight loss is seen for the treated sample at 500˚C for 6 h. Finally, it is observed from the potentiodynamic polarization test of the sample treated at 550˚C for 6 h has the minimum corrosion rate of 446.20 mm/year × 10−3.

Similar content being viewed by others

References

Alves Jr C, Da Silva E.F, Martinelli A.E, Surf Coat Technol 139 (2001) 1. https://doi.org/10.1016/S0257-8972(00)01146-4

Ahangarani Sh, Mahboubi F, and Sabour AR, Vacuum 80 (2006) 1032. https://doi.org/10.1016/j.vacuum.2006.01.013

Li CX, Bell T, Dong H, Surf Eng 18 (2002) 174. https://doi.org/10.1179/026708401225005250

Kumar N, Ganguli B, Roy B, and Deb B, Trans Indian Inst Met (2021). https://doi.org/10.1007/s12666-021-02191-z

Zhao C, Li CX, Dong H, and Bell T. Surf Coat Technol 201 (2006) 2320. https://doi.org/10.1016/j.surfcoat.2006.04.014

Rao K.R.M, Nouveau C, and Trinadh K, Trans Indian Inst Met 73 (2020)1695. https://doi.org/10.1007/s12666-020-02013-8

Li CX, Bell T, Wear 256 (2004)1144. https://doi.org/10.1016/j.wear.2003.07.006

Cleugh D, Surf Eng 18(2) (2002) 133. https://doi.org/10.1179/026708402225002802

Perumal G, Geetha M, Asokamani R, Alagumurthi N, Trans Indian Inst Met 66 (2013)109. https://doi.org/10.1007/s12666-012-0234-6

Berg M, Budtz-Jørgensen CV, Reitz H, Schweitz KO, Chevallier J, Kringhøj P, et al. Surf Coat Technol 124 (2000) 25. https://doi.org/10.1016/S0257-8972(99)00472-7

Borgioli F, Galvanetto E, Fossati A, and Bacci T, Surf Coat Technol 162 (2002) 61. https://doi.org/10.1016/S0257-8972(02)00574-1

C. X. Li, Surf Eng 26(3) (2010) 1. https://doi.org/10.1179/174329409X439032

De Sousa R.R.M, De Araújo F.O, Gontijo L.C, Da Costa J.A.P, and Jr Alves C, Vacuum 86 (2012) 2048. https://doi.org/10.1016/j.vacuum.2012.05.008

Wang L, Li Y, and Wu X, Appl. Surf Sci 254 (2008) 6595. https://doi.org/10.1016/j.apsusc.2008.04.027

Figueroa U, Oseguera J, Schabes-Retchkinam P.S, Surf Coat Technol 728 (1996) 86. https://doi.org/10.1016/S0257-8972(96)03058-7

Metin E, O.T. Inal J Mater Sci 22 (1987) 2783. https://doi.org/10.1007/BF01086471

Corengia P, Ybarra G, Moina C, Cabo A, and Broitman E, Surf Coat Technol 200 (2005) 2391. https://doi.org/10.1016/j.surfcoat.2005.01.060

Saeed A, Khan A W, Jan F, Abrar M, Khalid M, Zakaullah M, Appl Surf Sci 273 (2013) 173. https://doi.org/10.1016/j.apsusc.2013.02.008

Gautam D, Ganguli B, and Sharma S, Mater Perform Characterization 6 (2017) 581. https://doi.org/10.1520/MPC20160084

Bell T, Sun Y, and Suhadi A, Vacuum 59 (2000) 14. https://doi.org/10.1016/S0042-207X(00)00250-5

Wöhrle T, Thermodynamics and Kinetics of Phase Transformations in the Fe-N-C System, Dissertation. Stuttgart: Fakultät Chemie der Universität Stuttgart, 2012 (142 pp.), (2012).

Lei M.K, Zhang Z.L, Surf Coat Technol 91 (1997) 25. https://doi.org/10.1016/S0257-8972(96)03155-6

Liapina T, Leineweber E.J, and Mittemeijer A, Metall Mater Trans A 37 (2006) 319. https://doi.org/10.1007/s11661-006-0003-4

Nikolussi M, Leineweber A, Bischoff E, Mittemeijer E.J, Int J Mat Red 98 (2007) 1086. https://doi.org/10.3139/146.101576

Lampe T, S Eisenberg, and Laudien G, Surf Eng 9 (1993) 69. https://doi.org/10.1179/sur.1993.9.1.69

Jacobs H, Rechenbach D, and Zachwieja U, J Alloys Comp 227 (1995) 10. https://doi.org/10.1016/0925-8388(95)01610-4

Ahangarani Sh, Sabour A.R, Mahboubi F, and Shahrabi T, J Alloys Comp 484 (2009) 222. https://doi.org/10.1016/j.jallcom.2009.03.161

C.X. Li, T. Bell, Corrosion Science 46 (6) (2004) 1527. https://doi.org/10.1016/j.corsci.2003.09.015

Nakata K, Yamauchi W, Akamatsu K, Ushio M, Surf Coat Technol 174 (2003) 1206. https://doi.org/10.1016/S0257-8972(03)00459-6

Asadi Z.S, Mahboubi F, Mater & Des. 34 (2012) 516. https://doi.org/10.1016/j.matdes.2011.04.066

Kniess C T, Lima J C D and Prates P B, in Sintering – Methods and Products, (ed) Shatokha V, London (2012) p 294.

Ramboa K D M, Ferreira M C M, J Braz Chem Soc 26 (2015) 1491. http://dx.doi.org/https://doi.org/10.5935/0103-5053.201

Shen H, Wang L, Surf Coat Technol 378 (2019)124953. https://doi.org/10.1016/j.surfcoat.2019.124953

Liang W, Bin X, Zhiwei Y, & Yaqin S, Surf Coat Technol 130 (2000) 304. https://doi.org/10.1016/S0257-8972(00)00713-1

Naeem M, Shafiq M, Zaka-ul-Islam M, Ashiq A, Díaz-Guillén J C, Shahzad M, Zakaullah M, Mater & Des 108 (2016) 745. https://doi.org/10.1016/j.matdes.2016.07.044

Acknowledgements

The authors would like to acknowledge the contribution of Mr. Hardik Patel, Scientific Assistant-C, Institute for Plasma Research Gandhinagar, India, Mr. Subrat Kumar Das, Scientific Assistant-C (for SEM) and Mr. Vyom Desai, PhD scholar (for XRD analysis) from Facilitation Centre for Industrial Plasma Technologies Gandhinagar, India, in this study.

Funding

This study does not contain any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare no conflict of interest involved in the present study.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumar, N., Roy, B., Ganguli, B. et al. Influence of Treatment Time and Temperature on Surface Property of Active Screen Plasma-Nitrided EN24 Low Alloy Steel. Trans Indian Inst Met 74, 2027–2041 (2021). https://doi.org/10.1007/s12666-021-02299-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02299-2