Abstract

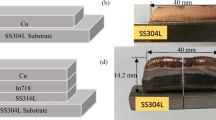

In Liquid Composite Molding (LCM), a fabric can be formed by highly double curved punch geometries. During the forming step, various types of defects can appear and may have a significant influence on the mechanical properties of the final composite materials. Till now, these defects have not been fully studied and/or understood. The aim of this study was to understand the mechanisms leading to the forming of mesoscopic defects (buckles and sliding), as well as their effect on the behavior of composite materials. To achieve this goal, an experimental machine was designed and built. The machine generates different types of defects, with controlled and adjusted amplitudes (calibrated defects) in samples of a fabric. These samples were then used to manufacture composite samples with calibrated defects, by an LCM process, in order to test and compare them with composite samples without defects. Thanks to this machine, calibrated forming defects that simulate the defects of an LCM process were generated, and the experimental parameters corresponding to the appearance of these defects were defined for two types of fabrics based on glass and carbon fibers. This work provides insight into the forming mechanisms of the buckle and sliding defects that occur during an LCM process.

Similar content being viewed by others

References

Li M, Wang P, Boussu F, Soulat D (2020) A review on the mechanical performance of three-dimensional warp interlock woven fabrics as reinforcement in composites. J Ind Text. https://doi.org/10.1177/1528083719894389

Allaoui S, Cellard C, Hivet G (2015) Effect of inter-ply sliding on the quality of multilayer interlock dry fabric preforms. Compos Part Appl Sci Manuf 68:336–345. https://doi.org/10.1016/j.compositesa.2014.10.017

Shanwan A, Allaoui S (2018) Different experimental ways to minimize the preforming defects of multi-layered interlock dry fabric. Int J Mater Form 12(1):69–78. https://doi.org/10.1007/s12289-018-1407-6

Farboodmanesh S, Chen J, Tao Z, Mead J, Zhang H (2010) Base fabrics and their interaction in coated fabrics. In:Smith WC (eds) Smart Textile Coatings and Laminates. Woodhead Publishing Series in Textiles (2010), pp 42–94. https://doi.org/10.1533/9781845697785.1.42

Alshahrani H, Mohan R, Hojjati M (2015) Experimental investigation of in-plane shear deformation of out-of-autoclave Prepreg. Int J Compos Mater 5(4):81–87 http://article.sapub.org/10.5923.j.cmaterials.20150504.03.html

Khan MA, Mabrouki T, Vidal-Sallé E, Boisse P (2010) Numerical and experimental analyses of woven composite reinforcement forming using a hypoelastic behaviour. Application to the double dome benchmark. J Mater Process Technol 210(2):378–388. https://doi.org/10.1016/j.jmatprotec.2009.09.027

Hivet G, Duong AV (2011) A contribution to the analysis of the intrinsic shear behavior of fabrics. J Compos Mater 45(6):695–716. https://doi.org/10.1177/0021998310382315

Lomov SV, Boisse P, Deluycker E, Morestin F, Vanclooster K, Vandepitte D, Verpoest I, Willems A (2008) Full-field strain measurements in textile deformability studies. Compos Part Appl Sci Manuf 39(8):1232–1244. https://doi.org/10.1016/j.compositesa.2007.09.014

Rothe S, Wendt E, Krzywinski S, Halász M, Bakonyi P, Tamás P, Bojtos A (2019) Investigation of shear-induced deformation of reinforcing textiles by optical measurement devices. Materials 12(7):1029. https://doi.org/10.3390/ma12071029

Barbagallo G, Madeo A, Azehaf I, Giorgio I, Morestin F, Boisse P (2017) Bias extension test on an unbalanced woven composite reinforcement: experiments and modeling via a second-gradient continuum approach. J Compos Mater 51(2):153–170. https://doi.org/10.1177/0021998316643577

Boisse P, Hamila N, Guzman-Maldonado E, Madeo A, Hivet G, Dell’Isola F (2017) The bias-extension test for the analysis of in-plane shear properties of textile composite reinforcements and prepregs: a review. Int J Mater Form 10(4):473–492. https://doi.org/10.1177/0021998316643577

Cao J, Akkerman R, Boisse P, Chen J, Cheng HS, De Graaf EF, Gorczyca JL, Harrison P, Hivet G, Launay J, Lee W, Liu L, Lomov SV, Long A, DeLuycker E, Morestin F, Padvoiskis J, Peng XQ, Zhu B (2008) Characterization of mechanical behavior of woven fabrics: experimental methods and benchmark results. Compos Part Appl Sci Manuf 39(6):1037–1053. https://doi.org/10.1016/j.compositesa.2008.02.016

Rashidi A, Milani AS (2018) Passive control of wrinkles in woven fabric preforms using a geometrical modification of blank holders. Compos Part Appl Sci Manuf 105:300–309. https://doi.org/10.1016/j.compositesa.2017.11.023

Nosrat Nezami F, Gereke T (May 2016) Cherif C (2016) analyses of interaction mechanisms during forming of multilayer carbon woven fabrics for composite applications. Compos Part Appl Sci Manuf 84:406–416. https://doi.org/10.1016/j.compositesa.2016.02.023

Allaoui S, Hivet G, Soulat D, Wendling A, Ouagne P, Chatel S (2014) Experimental preforming of highly double curved shapes with a case corner using an interlock reinforcement. Int J Mater Form 7(2):155–165. https://doi.org/10.1007/s12289-012-1116-5

Boisse P, Hamila N Madeo a (2016) modelling the development of defects during composite reinforcements and prepreg forming. Philos Trans R Soc A Math Phys Eng Sci 374(2071):20150269. https://doi.org/10.1098/rsta.2015.0269

Zhao C, Yang B, Wang S, Ma C, Wang S, Bi F (2019) Three-dimensional numerical simulation of Meso-scale-void formation during the Mold-filling process of LCM. Appl Compos Mater 26(4):1121–1137. https://doi.org/10.1007/s10443-019-09770-w

Cruanes C, Shanwan A, Méo S, Allaoui S, Deffarges MP, Lacroix F, Hivet G (2018) Effect of mesoscopic out-of-plane defect on the fatigue behavior of a GFRP. Mech Mater 117:214–224. https://doi.org/10.1016/j.mechmat.2017.11.008

Kacimi B, Djebbar A, Allaoui S, Hivet G, Teklal F (2019) Effect of reinforcement shear and mesoscopic defects on the low velocity impact behavior of a GFRP. Int J Mater Form. https://doi.org/10.1007/s12289-019-01521-3

Zhao C, Xiao J, Li Y, Chu Q, Xu T, Wang B (2017) An experimental study of the influence of in-plane Fiber waviness on unidirectional laminates tensile properties. Appl Compos Mater 24:1321–1337. https://doi.org/10.1007/s10443-017-9590-z

Croft K, Lessard L, Pasini D, Hojjati M, Chen J, Yousefpour A (2011) Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos Part Appl Sci Manuf 42(5):484–491. https://doi.org/10.1016/j.compositesa.2011.01.007

Wu C, Gu Y, Luo L, Xu P, Wang S, Li M, Zhang Z (2018) Influences of in-plane and out-of-plane fiber waviness on mechanical properties of carbon fiber composite laminate. J Reinf Plast Compos 37(13):877–891. https://doi.org/10.1177/0731684418765981

Lightfoot JS, Wisnom MR, Potter K (2013) Defects in woven preforms: formation mechanisms and the effects of laminate design and layup protocol. Compos Part Appl Sci Manuf 51:99–107. https://doi.org/10.1016/j.compositesa.2013.04.004

Boisse P, Hamila N, Vidal-Sallé E, Dumont F (2011) Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses. Compos Sci Technol 71(5):683–692. https://doi.org/10.1016/j.compscitech.2011.01.011

Hosseini A, Kashani MH, Sassani F, Milani AS, Ko FK (2018) Identifying the distinct shear wrinkling behavior of woven composite preforms under bias extension and picture frame tests. Compos Struct 185:764–773. https://doi.org/10.1016/j.compstruct.2017.11.033

Härtel F, Middendorf P (2013) Process parameters studies and comparison of different preform processes with NCF material, proceeding of ICCM-19, Montreal

Mallach A, Härtel F, Heieck F, Fuhr JP, Middendorf P, Gude M (2017) Experimental comparison of a macroscopic draping simulation for dry non-crimp fabric preforming on a complex geometry by means of optical measurement. J Compos Mater 51(16):2363–2375. https://doi.org/10.1177/0021998316670477

Bel S, Hamila N, Boisse P, Dumont F (2012) Finite element model for NCF composite reinforcement preforming: importance of inter-ply sliding. Compos Part Appl Sci Manuf 43(12):2269–2277. https://doi.org/10.1016/j.compositesa.2012.08.005

Labanieh AR, Garnier C, Ouagne P, Dalverny O, Soulat D (2018) Intra-ply yarn sliding defect in hemisphere preforming of a woven preform. Compos Part Appl Sci Manuf 107:432–446. https://doi.org/10.1016/j.compositesa.2018.01.018

Gatouillat S, Bareggi A, Vidal-Sallé E, Boisse P (2013) Meso modelling for composite preform shaping – simulation of the loss of cohesion of the woven fibre network. Compos Part Appl Sci Manuf 54:135–144. https://doi.org/10.1016/j.compositesa.2013.07.010

Capelle E, Ouagne P, Soulat D, Duriatti D (2014) Complex shape forming of flax woven fabrics: design of specific blank-holder shapes to prevent defects. Compos Part B Eng 62:29–36. https://doi.org/10.1016/j.compositesb.2014.02.007

Tephany C, Gillibert J, Ouagne P, Hivet G, Allaoui S, Soulat D (2016) Development of an experimental bench to reproduce the tow buckling defect appearing during the complex shape forming of structural flax based woven composite reinforcements. Compos Part Appl Sci Manuf 81:22–33. https://doi.org/10.1016/j.compositesa.2015.10.011

Salem MM, De Luycker E, Fazzini M, Ouagne P (2019) Experimental, analytical and numerical investigation to prevent the tow buckling defect during fabric forming. Compos Part Appl Sci Manuf 125:105567. https://doi.org/10.1016/j.compositesa.2019.105567

Soulat D, Allaoui S, Chatel S (2009) Experimental device for the preforming step of the RTM process. Int J Mater Form 2(1):181. https://doi.org/10.1007/s12289-009-0568-8

Allaoui S, Launay J, Soulat D, Chatel S (2008) Experimental tool of woven reinforcement forming. Int J Mater Form 1(1):815–818. https://doi.org/10.1007/s12289-008-0260-4

Hivet G, Allaoui S, Cam BT, Ouagne P, Soulat D (2012) Design and potentiality of an apparatus for measuring yarn/yarn and fabric/fabric friction. Exp Mech 52(8):1123–1136. https://doi.org/10.1007/s11340-011-9566-0

Wendling A, Hivet G, Vidal-Sallé E, Boisse P (2014) Consistent geometrical modelling of interlock fabrics. Finite Elem Anal Des 90:93–105. https://doi.org/10.1016/j.finel.2014.05.010

Launay J, Hivet G, Duong AV, Boisse P (2008) Experimental analysis of the influence of tensions on in plane shear behavior of woven composite reinforcements. Compos Sci Technol 68(2):506–515. https://doi.org/10.1016/j.compscitech.2007.06.021

Harrison P, Abdiwi F, Guo Z, Potluri P, Yu WR (2012) Characterising the shear–tension coupling and wrinkling behaviour of woven engineering fabrics. Compos Part Appl Sci Manuf 43(6):903–914. https://doi.org/10.1016/j.compositesa.2012.01.024

Zhou Y, Ali M, Gong X, Yang D (2017) An overview of yarn pull-out behavior of woven fabrics. Text Res J. https://doi.org/10.1177/0040517517741156

Acknowledgments

The authors would like to thank the Centre Val-de-Loire for financing this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shanwan, A., Allaoui, S., Gillibert, J. et al. Development and Implementation of an Experimental Machine to Study Woven Fabric Preforming Defects. Exp Tech 46, 299–316 (2022). https://doi.org/10.1007/s40799-021-00483-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-021-00483-z