Abstract

The precise control of nanostructure and surface atomic arrangement can be used to tune the electrocatalytic properties of materials and improve their performance. Unfortunately, the long-term structural stability of electrocatalysts with complex nanoscale morphology, a necessary requirement for industrial implementation, often remains elusive. Here we study how electrochemical and complex current behaviours affect the nanoscale object and its structural stability during electrocatalysis. We find that metal electromigration can drive structural transformation during electrolysis to minimize current crowding in nanoscale geometric constrictions. This electrical phenomenon, acting in combination with electrochemically induced atomic migration, can result in specific structural transformations of the catalyst, with the extent and rate depending on the material, geometry and reaction. Using a series of nanostructure examples, we establish a general framework for evaluating the structural transformations in cathodic metal nanocatalysts and explain specific qualitative trends. In conjunction with catalyst design rules, this mechanistic framework will facilitate the development of nanostructured electrocatalysts with sufficient stability for sustainable applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. The data generated and/or analysed during the current study are available within the article and its Supplementary Information files or from the corresponding author upon reasonable request.

References

Liu, L. & Corma, A. Metal catalysts for heterogeneous catalysis: from single atoms to nanoclusters and nanoparticles. Chem. Rev. 118, 4981–5079 (2018).

Koper, M. T. M. Structure sensitivity and nanoscale effects in electrocatalysis. Nanoscale 3, 2054–2073 (2011).

Trindell, J. A., Duan, Z., Henkelman, G. & Crooks, R. M. Well-defined nanoparticle electrocatalysts for the refinement of theory. Chem. Rev. 120, 814–850 (2020).

Gao, D., Aran-Ais, R. M., Jeon, H. S. & Cuenya, B. R. Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat. Catal. 2, 198–210 (2019).

Park, J. et al. Hollow nanoparticles as emerging electrocatalysts for renewable energy conversion reactions. Chem. Soc. Rev. 47, 8173–8202 (2018).

Zhuang, T.-T. et al. Copper nanocavities confine intermediates for efficient electrosynthesis of C3 alcohol fuels from carbon monoxide. Nat. Catal. 1, 946–951 (2018).

Liu, M. et al. Enhanced electrocatalytic CO2 reduction via field-induced reagent concentration. Nature 537, 382–386 (2016).

Zhang, L. et al. Copper–palladium tetrapods with sharp tips as a superior catalyst for the oxygen reduction reaction. ChemCatChem 10, 925–930 (2018).

Chen, C. et al. Sharp Cu@Sn nanocones on Cu foam for highly selective and efficient electrochemical reduction of CO2 to formate. J. Mater. Chem. A 6, 19621–19630 (2018).

Li, D. et al. Electrochemical reduction of carbon dioxide to formate via nano-prism assembled CuO microspheres. Chemospere 237, 124527 (2019).

Safaei, T. S. et al. High-density nanosharp microstructures enable efficient CO2 electroreduction. Nano Lett. 16, 7224–7228 (2016).

Xiao, D. et al. Atomic-scale intercalation of graphene layers into MoSe2 nanoflower sheets as a highly efficient catalyst for hydrogen evolution reaction. ACS Appl. Mater. Interfaces 12, 2460–2468 (2020).

Kim, S. et al. Shape-controlled bismuth nanoflakes as highly selective catalysts for electrochemical carbon dioxide reduction to formate. Nano Energy 39, 44–52 (2017).

Xia, Z. et al. Highly selective electrochemical conversion of CO2 to HCOOH on dendric indium foams. ChemElectroChem 5, 253–259 (2018).

Ni, W. et al. Fluorine doped cagelike carbon electrocatalyst: an insight into the structure-enhanced CO selectivity for CO2 reduction at high overpotential. ACS Nano 14, 2014–2023 (2020).

Kim, D., Kley, C. S., Li, Y. & Yang, P. Copper nanoparticle ensembles for selective electroreduction of CO2 to C2–C3 products. Proc. Natl Acad. Sci. USA 114, 10560–10565 (2017).

Li, Y. et al. Electrochemically scrambled nanocrystals are catalytically active for CO2-to-multicarbons. Proc. Natl Acad. Sci. USA 117, 9194–9201 (2020).

Pattadar, D. K. & Zamborini, F. P. Size stability study of catalytically active sub‑2 nm diameter gold nanoparticles synthesized with weak stabilizers. J. Am. Chem. Soc. 140, 14126–14133 (2018).

Osowiecki, W. T. et al. Factors and dynamics of Cu nanocrystal reconstruction under CO2 reduction. ACS Appl. Energy Mater. 2, 7744–7749 (2019).

Manthiram, K., Surendranath, Y. & Alivisatos, A. P. Dendric assembly of gold nanoparticles during fuel-forming electrocatalysis. J. Am. Chem. Soc. 136, 7237–7240 (2014).

Khairullina, E. et al. An aligned octahedral core in a nanocage: synthesis, plasmonic, and catalytic properties. Nanoscale 11, 3138–3144 (2019).

Choi, S., Moon, Y. & Yoo, H. Finely tunable fabrication and catalytic activity of gold multipod nanoparticles. J. Colloid Interface Sci. 469, 269–276 (2016).

Klinkova, A., Larin, E. M., Prince, E., Sargent, E. H. & Kumacheva, E. Large-scale synthesis of metal nanocrystals in aqueous suspensions. Chem. Mater. 28, 3196–3202 (2016).

Herrero, E., Buller, L. J. & Abruna, H. D. Underpotential deposition at single crystal surfaces of Au, Pt, Ag and other materials. Chem. Rev. 101, 1897–1930 (2001).

Hamelin, A. J. Lead adsorption on gold single crystal stepped surfaces. J. Electroanal. Chem. 101, 285–290 (1979).

Hamelin, A. & Katayama, A. Lead underpotential deposition on gold single-crystal surfaces: the (100) face and its vicinal faces. J. Electroanal. Chem. 117, 221–232 (1981).

Hamelin, A. Underpotential deposition of lead on single crystal faces of gold: part I. The influence of crystallographic orientation of the substrate. J. Electroanal. Chem. 165, 167–180 (1984).

Hamelin, A. & Lipkowski, J. Underpotential deposition of lead on gold single crystal faces: part II. General discussion. J. Electroanal. Chem. 171, 317–330 (1984).

Hernández, J., Solla-Gullón, J. & Herrero, E. Gold nanoparticles synthesized in a water-in-oil microemulsion: electrochemical characterization and effect of the surface structure on the oxygen reduction reaction. J. Electroanal. Chem. 574, 185–196 (2004).

Shah, A. H. et al. Revisiting electrochemical reduction of CO2 on Cu electrode: where do we stand about the intermediates? J. Phys. Chem. C. 122, 18528–18536 (2018).

Calvinho, K. U. D. et al. Selective CO2 reduction to C3 and C4 oxyhydrocarbons on nickel phosphides at overpotentials as low as 10 mV. Energy Environ. Sci. 11, 2550–2559 (2018).

Belding, S. R., Campbell, F. W., Dickinson, E. J. F. & Compton, R. G. Nanoparticle-modified electrodes. Phys. Chem. Chem. Phys. 12, 11208–11221 (2010).

Wang, H. & Pilon, L. Accurate simulations of electric double layer capacitance of ultramicroelectrodes. J. Phys. Chem. C 115, 16711–16719 (2011).

Yasunaga, H. & Natori, A. Electromigration on semiconductor surfaces. Surf. Sci. Rep. 15, 205–280 (1992).

Min, X., Chen, Y. & Kanan, M. W. Alkaline O2 reduction on oxide-derived Au: high activity and 4e− selectivity without (100) facets. Phys. Chem. Chem. Phys. 16, 13601–13604 (2014).

Su, D. S., Zhang, B. & Schlög, R. Electron microscopy of solid catalysts transforming from a challenge to a toolbox. Chem. Rev. 115, 2818–2882 (2015).

Love, G., Scott, V. D., Dennis, N. M. T. & Laurenson, L. Sources of contamination in electron optical equipment. Scanning 4, 32–39 (1981).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Bader, R. F. W. A quantum theory of molecular structure and its applications. Chem. Rev. 91, 893–928 (1991).

Tang, W., Sanville, E. & Henkelman, G. A grid-based Bader analysis algorithm without lattice bias. J. Phys. Condens. Matter 21, 084204 (2009).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A. Climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Aguilella-Arzo, M., Andrio, A., Aguilella, V. M. & Alcaraz, A. Dielectric saturation of water in a membrane protein channel. Phys. Chem. Chem. Phys. 11, 358–365 (2009).

Serway, R. A. & Jewett, J. W. Principles of Physics Vol. 1, 602 (Saunders College Publishing, 1998).

Matula, R. A. Electrical resistivity of copper, gold, palladium, and silver. J. Phys. Chem. Ref. Data 8, 1147–1298 (1979).

Acknowledgements

We thank L. Nazar for help with the DFT calculations, S. Tatarchuk for help with FEM computing and O. Voznyy for fruitful discussions. F.L. is grateful for the Nanofellowship provided by the Waterloo Institute for Nanotechnology. Y.G. thanks the China Scholarship Council for the fellowship. A.K. is grateful to the University of Waterloo startup funding, the Discovery Grant and the Research Tools and Instruments funding provided by the Natural Sciences and Engineering Research Council of Canada, the Canada Foundation for Innovation John R. Evans Leaders Fund (award no. 38060) and the Ontario Research Fund: Small Infrastructure. H.T.-A. acknowledges the financial support from the Max Planck Society. A.A. acknowledges California State University Long Beach internal research funding.

Author information

Authors and Affiliations

Contributions

A.K. conceived the idea, supervised the project and wrote the manuscript. F.L. designed and carried out the DFT calculations and the FEM simulations and assisted in manuscript writing. X.V.M. designed experiments and performed the nanoparticle synthesis, carried out the electrochemical experiments, conducted the SEM characterization and assisted in manuscript writing. J.J.M. performed electrochemical experiments and product analysis and conducted the literature survey summarized in Supplementary Tables 1–3. E.K. performed the nanoparticle synthesis and the electrochemical experiments. H.E. assisted with the nanoparticle synthesis and helped to organize the supplementary materials. S.C. assisted with the FEM simulations. J.J. assisted with the Joule heating simulations. A.A. assisted with running and analysing the FEM simulations. Y.G. assisted with the nanoparticle synthesis. A.L. assisted with data analysis. H.T.-A., A.A. and Y.P. contributed to data analysis and manuscript polishing. All authors discussed the results and assisted during manuscript preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Catalysis thanks the anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

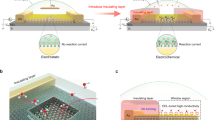

Extended Data Fig. 1 Electrochemical performance and stability of Au CCs and BNPs.

a-c, CO2 reduction activity of Au BNPs (a,b) and Au CCs (c) over time during potentiostatic electrolysis at −0.6 V (a,c) and −1.2 V (b) vs RHE in CO2-saturated 0.5 M KHCO3. d-g, Cyclic voltammograms of Au BNPs (d,e) and Au CCs (f,g) before and after 5 hours of potentiostatic electrolysis at −0.6 V vs RHE in CO2-saturated (d,f) or Ar-saturated 0.5 M KHCO3 (e,g). Current densities correspond to currents normalized by the geometric area of the electrode. For surface roughness analysis of these electrodes see Supplementary Table 5.

Extended Data Fig. 2 Structural stability of Pd CCs and BNPs under CO2 reduction conditions.

a-d, SEM images areas of Pd CCs before (a,c) and after (b,d) 300 min of CO2RR reaction at −1.2 V vs RHE at different magnifications. e-h, SEM images of Pd CCs with a more open wall morphology before (e,g) and after (f,h) 300 min of CO2RR reaction at −1.2 V vs RHE at different magnifications. i-n, SEM images of Pd BNPs before (i,l), after 120 min (j,m), and after 300 min (k,n) of CO2RR reaction at −1.2 V vs RHE at different magnifications.

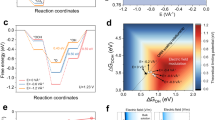

Extended Data Fig. 3 Charge distribution profiles for different Ay facets with surface-bound intermediates *COOH or *H.

a–c, Side view of Au(111), Au(110) and Au(211). d-g, Top view of Au(111), Au(100), Au(110) and Au(211). Yellow and blue colors represent the charge accumulation and depletion, with an iso-surface value of 0.001 e/Å3 implemented.

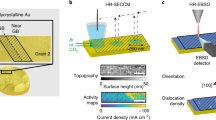

Extended Data Fig. 4 Effects of geometry, material, and interelectrode distance on computed current density and E-field.

a, Computed current density distribution in Pd BNPs. b-d, average current density within the Debye length, Jelectrolyte (b), average current density within the electrode, Jmetal (c) and average E-field within the Stern layer (d), as the function of the distance between anode and cathode. e, Computed current density distribution in a Au CC tetramer with the geometry shown in the inset; three CCs in the front of the structure are hidden from the view to reveal the current distribution at the interfaces between the particles and at the particle-substrate interfaces. In (a) and (e) Jmetal is shown as colour maps, and Jelectrolyte at the nanostructure surface is shown as a group of yellow arrows, where the size and direction of each arrow represent the magnitude and direction of current at the spatial position of the arrow, respectively. Scale bars are 25 nm.

Supplementary information

Supplementary Information

Supplementary Notes 1–3, Methods, Tables 1–5, Figs. 1–30 and References.

Source data

Source Data Fig. 3

Optimized geometries for NEB and charge distribution calculations.

Source Data Extended Data Fig. 3

Optimized geometries for charge distribution calculations.

Rights and permissions

About this article

Cite this article

Li, F., Medvedeva, X.V., Medvedev, J.J. et al. Interplay of electrochemical and electrical effects induces structural transformations in electrocatalysts. Nat Catal 4, 479–487 (2021). https://doi.org/10.1038/s41929-021-00624-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-021-00624-y

This article is cited by

-

Impact of palladium/palladium hydride conversion on electrochemical CO2 reduction via in-situ transmission electron microscopy and diffraction

Nature Communications (2024)

-

In situ electrochemical Raman spectroscopy and ab initio molecular dynamics study of interfacial water on a single-crystal surface

Nature Protocols (2023)

-

Steering surface reconstruction of copper with electrolyte additives for CO2 electroreduction

Nature Communications (2022)

-

External field-strengthened Ostwald nanowelding

Nano Research (2022)

-

Electrocatalyst nanoparticles go with the flow

Nature Catalysis (2021)