Abstract

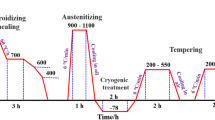

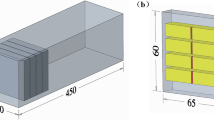

55NiCrMoV7 hot-work die steel is mainly used to manufacture heavy forgings in the fields of aerospace and automobile. This study aims to clarify the effects of heat treatment on the microstructural evolution and mechanical properties of the steel, in order to find out an optimal heat treatment scheme to obtain an excellent balance of strength, ductility and toughness. The steel was quenched at temperature from 790 °C to 910 °C followed by tempering treatments of 100–650 °C for 5 h. The mechanical property tests were carried out by tensile, impact toughness and hardness. Optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM) were used to observe the austenite grains, lath martensite, carbides and fracture morphology. The results show that the quenching temperature mainly influences the austenite grain size and the volume fraction of undissolved carbides (UCs), while the tempering temperature mainly influences the size and morphology of the martensite with a body centered cubic (BCC) and the carbides with a face centered cubic (FCC). The mechanical properties of the steel, including yield and tensile strength, ductility, impact toughness and hardness, get an excellent balance at a quenching range of 850–870 °C. As the tempering temperature increases, the yield and tensile strength and hardness decrease, while the ductility and impact toughness increase. These variation trends can be further verified by fracture SEM observation and analysis. Combined with a macro-micro coupled finite element (MMFE) modeling technique, the cooling rate, microstructural evolution and yield strength of the steel were predicted and compared with the tested data.

Similar content being viewed by others

References

Velay V, Bernhart G, Penazzi L (2006) Cyclic behavior modeling of a tempered martensitic hot work tool steel. Int J Plasticity 22(3):459–496

Zhang Z, Delagnes D, Bernhart G (2007) Ageing effect on cyclic plasticity of a tempered martensitic steel. Int J Fatigue 29(2):336–346

Zhu J, Zhang ZH, Xie JX (2019) Improving strength and ductility of H13 die steel by pre-tempering treatment and its mechanism. Mater Sci Eng A 752(3):101–114

Li JY, Chen YL, Huo JH (2015) Mechanism of improvement on strength and toughness of H13 die steel by nitrogen. Mater Sci Eng A 640:16–23

Li JY, Zhao P, Yanagimoto J et al (2012) Effects of heat treatment on the microstructures and mechanical properties of a new type of nitrogen-containing die steel. Int J Miner Metall Mater 19(6):511–517

Pérez M, Rodríguez C, Belzunce FJ (2014) The use of cryogenic thermal treatments to increase the fracture toughness of a hot work tool steel used to make forging dies. Proc Mater Sci 3:604–609

Yan ZJ, Liu K, Eckert J (2020) Effect of tempering and deep cryogenic treatment on microstructure and mechanical properties of Cr-Mo-V-Ni steel. Mater Sci Eng A 787:139520. https://doi.org/10.1016/j.msea.2020.139520

Weng ZJ, Gu KX, Wang KK et al (2020) The reinforcement role of deep cryogenic treatment on the strength and toughness of alloy structural steel. Mater Sci Eng A. 772: 138698. https://doi.org/10.1016/j.msea.2019.138698

Peng F, Xu YB, Han DT et al (2019) In influence of pre-tempering treatment on microstructure and mechanical properties in quenching and partitioning steels with ferrite-martensite start structure. Mater Sci Eng A 756:248–257

Luo H, Shi J, Wang C et al (2011) Experimental and numerical analysis on formation of stable austenite during the intercritical annealing of 5 Mn steel. Acta Mater 59(10):4002–4014

Åsberg M, Fredriksson G, Hatami S et al (2019) In influence of post treatment on microstructure, porosity and mechanical properties of additive manufactured H13 tool steel. Mater Sci Eng A 742:584–589

Ali M, Porter D, Kömi J et al (2019) The effect of double austenitization and quenching on the microstructure and mechanical properties of CrNiMoWMnV ultrahigh-strength steels after low-temperature tempering. Mater Sci Eng A 763:138169. https://doi.org/10.1016/j.msea.2019.138169

Chen K, Jiang ZH, Liu FB et al (2020) Enhanced mechanical properties by retained austenite in medium-carbon Si-rich microalloyed steel treated by quenching-tempering, austempering and austempering-tempering processes. Mater Sci Eng A 790:139742. https://doi.org/10.1016/j.msea.2020.139742

Zhou QC, Wu XC, Shi NN et al (2011) Microstructure evolution and kinetic analysis of DM hot-work die steels during tempering. Mater Sci Eng A 528(8):5696–5700

Zhang YP, Zhan DP, Qi XW et al (2017) Microstructure and mechanical properties of Cr14 ultra-high-strength steel at different tempering temperatures around 773 K. Mater Sci Eng A 698:152–161

Liu HH, Fu PX, Liu HW et al (2018) Microstructure evolution and mechanical properties in 718H pre-hardened mold steel during tempering. Mater Sci Eng A 709:181–192

Saha DC, Biro E, Gerlich AP et al (2016) Effects of tempering mode on the structural changes of martensite. Mater Sci Eng A 673:467–475

Jebaraj M, Kumar MP, Anburaj R (2020) Effect of LN2 and CO2 coolants in milling of 55NiCrMoV7 steel. J Manuf Process 53:318–327

Zhang ZP, Qi YH, Delagnes D et al (2007) Microstructure variation and hardness diminution during low cycle fatigue of 55NiCrMoV7 steel. J Iron Steel Research Int 14:68–73

Egner H, Egner W (2014) Modeling of a tempered martensitic hot work tool steel behavior in the presence of thermo-viscoelastic coupling. Int J Plast 57:77–91

Sun C, Fu PX, Ma XP et al (2020) Effect of matrix carbon content and lath martensite microstructures on the tempered precipitates and impact toughness of a medium-carbon low-alloy steel. J Mater Res Technol 9(4):7701–7710

Wu C, Meng QL (2019) Microstructural evolution of a steam-turbine rotor subjected to a water-quenching process: numerical simulation and experimental verification. Adv Manuf 7:84–104

Morsdorf L, Tasan CC, Ponge D et al (2015) 3D structural and atomic-scale analysis of lath martensite: Effect of the transformation sequence. Acta Mater 95:366–377

He BB, Huang MX (2015) Revealing the intrinsic nanohardness of lath martensite in low carbon steel. Metall Mater Trans A 46:688–694

Maalekian M, Kozeschenik E, Chatterjee S et al (2007) Mechanical stabilisation of eutectoid steel. Mater Sci Technol 23:610–612

Tao XG, Han LZ, Gu JF (2014) Effect of tempering on microstructure evolution and mechanical properties of X12CrMoWVNbN10-1-1 steel. Mater Sci Eng A 618:189–204

Hoseiny H, Klement U, Sotskovszki P et al (2011) Comparison of the microstructures in continuous-cooled and quench-tempered pre-hardened mould steels. Mater Des 32:21–28

Garrison WM, Wojcieszynski AL (2007) A discussion of the effect of inclusion volume fraction on the toughness of steel. Mater Sci Eng A 464:321–329

Chen K, Jiang ZH, Liu FB et al (2019) Effect of quenching and tempering temperature on microstructure and tensile properties of micro-alloyed ultra-high strength suspension spring steel. Mater Sci Eng A 766:138272. https://doi.org/10.1016/j.msea.2019.138272

Lütjering G, Williams JC (2007) Titanium, (2nd edn). Springer, Berlin

Kim B, Boucard E, Sourmail T et al (2014) The influence of silicon in tempered martensite: understanding the microstructure properties relationship in 0.5–0.6 wt.% C steels. Acta Mater 68:169–178

Acknowledgement

The authors acknowledge with gratitude funding received from the fellowship of China Postdoctoral Science Foundation (Grant No. 2020M672309).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, XS., Wu, C., Shi, RX. et al. Microstructural evolution and mechanical properties of 55NiCrMoV7 hot-work die steel during quenching and tempering treatments. Adv. Manuf. 9, 520–537 (2021). https://doi.org/10.1007/s40436-021-00352-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-021-00352-3