Abstract

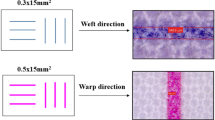

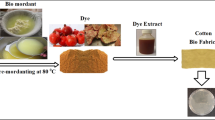

Current methods of fabric dyeing have a significant negative effect on the environment via toxic effluent emissions, high water usage, and high energy consumption. We demonstrate, for the first time, low-energy inkjet printing of an ecofriendly and biodegradable pigment derived from widely available spalting fungi with synthesis by-products that are fully biodegradable. Vivid and stable coloration is achieved on polyester and cotton using benign acetone-based and ethanol-based biopigment inks, with no liquid effluent or runoff, and without any synthetic dyes or mordants. We investigate the influence of fabric type, solvent type, and the number of printing passes on the color type, intensity, and uniformity, pigment crystallization, and environmental stability. Greater spatial definition of the printed pigment in inkjet printing effects greater crystallization and more vivid and uniform coloration as compared to drop-casting, the primary method used till date to color fabrics with such fungal biopigments. pH-driven interactions between the fabric, solvent, and biopigment cause solvent-driven changes in color type (from bluish to reddish) and fabric-governed changes in color intensity. The impact of our findings on minimizing the environmental impact of fabric dyeing is discussed.

Similar content being viewed by others

Availability of data

Data is available from the authors upon request.

References

Hicks, C., & Dietmar, R. (2007). Improving cleaner production through the application of environmental management tools in China. Journal of Cleaner Production, 15(5), 395–408. https://doi.org/10.1016/j.jclepro.2005.11.008

Perrut, M. (2000). Supercritical fluid applications: Industrial developments and economic issues. Industrial & Engineering Chemistry, 39, 4531–4535

Kadolph, S. J. (2011). Textiles. Upper Saddle River: Prentice Hall.

Zheng, H., & Zheng, L. (2014). Dyeing of meta-aramid fibers with disperse dyes in supercritical carbon dioxide. Fibers and Polymers, 15(8), 1627–1634

Kant, R. (2012). Textile dyeing industry and environmental hazard. Natural Science, 4(1), 22–26

Mangal, V. P. (2010). The future of Indian dyes & dye intermediates. Textile Review., 2010, 511

Chico, D., Aldaya, M. M., & Garrido, A. (2013). A water footprint assessment of a pair of jeans: The influence of agricultural policies on the sustainability of consumer products. Journal of Cleaner Production, 57, 238–248. https://doi.org/10.1016/j.jclepro.2013.06.001

Müller, J. M., & Voigt, K.-I. (2018). Sustainable industrial value creation in SMEs: A comparison between industry 4.0 and made in China 2025. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(5), 659–670. https://doi.org/10.1007/s40684-018-0056-z

Dornfeld, D. A. (2014). Moving towards green and sustainable manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology, 1(1), 63–66. https://doi.org/10.1007/s40684-014-0010-7

Park, C.-W., Kwon, K.-S., Kim, W.-B., Min, B.-K., Park, S.-J., Sung, I.-H., et al. (2009). Energy consumption reduction technology in manufacturing—a selective review of policies, standards, and research. International Journal of Precision Engineering and Manufacturing, 10(5), 151–173. https://doi.org/10.1007/s12541-009-0107-z

Park, K. T., Kang, Y. T., Yang, S. G., Zhao, W. B., Kang, Y.-S., Im, S. J., et al. (2020). Cyber physical energy system for saving energy of the dyeing process with industrial internet of things and manufacturing big data. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(1), 219–238. https://doi.org/10.1007/s40684-019-00084-7

Liu, Y., Shang, S., Mo, S., Wang, P., & Wang, H. (2020). Eco-friendly strategies for the material and fabrication of wearable sensors. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-020-00285-5

Zheng, H., Zhang, J., Yan, J., & Zheng, L. (2016). An industrial scale multiple supercritical carbon dioxide apparatus and its eco-friendly dyeing production. Journal of CO2 Utilization, 16, 272–281. https://doi.org/10.1016/j.jcou.2016.08.002

Reible, D. D. (2005). Hazardous substance research centers/South and South-West outreach program environmental hazards of the textile industry. Business Week, 2005, 910

Zaffalon, V. (2010). Climate change, carbon mitigation and textiles. Textile World, 160, 34

Hasanbeigi, A. (2013). Alternative and emerging technologies for an energy-efficient, water-efficient, and low-pollution textile industry. Lawrence Berkeley National Lab. (LBNL), Berkeley, CA (United States).

Montero, G., Smith, C. B., Hendrix, W., & Butcher, D. (2000). Supercritical fluid technology in textile processing: An overview. Industrial and Engineering Chemistry, 39, 4806–4812

Zheng, H., Xu, Y., Zhang, J., Xiong, X., Yan, J., & Zheng, L. (2017). An ecofriendly dyeing of wool with supercritical carbon dioxide fluid. Journal of Cleaner Production, 143, 269–277. https://doi.org/10.1016/j.jclepro.2016.12.115

Hasanbeigi, A., & Price, L. (2015). A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. Journal of Cleaner Production, 95, 30–44

Kim, T., Seo, B., Park, G., & Lee, Y.-W. (2019). Effects of dye particle size and dissolution rate on the overall dye uptake in supercritical dyeing process. The Journal of Supercritical Fluids, 151, 1–7. https://doi.org/10.1016/j.supflu.2019.05.006

Liu, M., Zhao, H., Wu, J., Xiong, X., & Zheng, L. (2018). Eco-friendly curcumin-based dyes for supercritical carbon dioxide natural fabric dyeing. Journal of Cleaner Production, 197, 1262–1267. https://doi.org/10.1016/j.jclepro.2018.06.202

Nimkulrat, N., Kane, F., & Walton, K. (2016). Crafting textiles in the digital age. London: Bloomsbury Publishing.

Tippett, B. G. (2002). The evolution and progression of digital textile printing. http://brookstippett.com/docs/Print2002-BGT.pdf. Accessed 2 Dec 2015.

Gupta, S. (2001). Inkjet printing—a revolutionary ecofriendly technique for textile printing. Indian Journal of Fibers & Textile Research, 26, 156–161

Xue, C., Shi, M., Chen, H., Wu, G., & Wang, M. (2006). Preparation and application of nanoscale microemulsion as binder for fabric inkjet printing. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 287, 147–152

Choi, S., Cho, K. H., Namgoong, J. W., Kim, J. Y., Yoo, E. S., Lee, W., et al. (2019). The synthesis and characterization of the perylene acid dye inks for digital textile printing. Dyes and Pigments, 163, 381–392. https://doi.org/10.1016/j.dyepig.2018.12.002

Ding, Y., Parrillo-Chapman, L., & Freeman, H. S. (2018). A study of the effects of fabric pretreatment on color gamut from inkjet printing on polyester. The Journal of The Textile Institute, 109(9), 1143–1151. https://doi.org/10.1080/00405000.2017.1415623

Wang, L., Hu, C., & Yan, K. (2018). A one-step inkjet printing technology with reactive dye ink and cationic compound ink for cotton fabrics. Carbohydrate Polymers, 197, 490–496. https://doi.org/10.1016/j.carbpol.2018.05.084

Wilson, J. H., Bradbury, R., Annable, T., & Yeates, S. G. (2012). Inkjet printable aqueous composite dye–polymer nanoparticles. Dyes and Pigments, 95(2), 201–205. https://doi.org/10.1016/j.dyepig.2012.04.005

Kaimouz, A. W., Wardman, R. H., & Christie, R. M. (2010). Ink-jet printing process for lyocell and cotton fibres. Part 2: The relationship of colour strength and dye fixation to ink penetration. Coloration Technology, 126(6), 342–347. https://doi.org/10.1111/j.1478-4408.2010.00267.x

Park, J.-Y., Hirata, Y., & Hamada, K. (2012). Relationship between the dye/additive interaction and inkjet ink droplet formation. Dyes and Pigments, 95(3), 502–511. https://doi.org/10.1016/j.dyepig.2012.04.019

Güngör, G. L., Kara, A., Gardini, D., Blosi, M., Dondi, M., & Zanelli, C. (2016). Ink-jet printability of aqueous ceramic inks for digital decoration of ceramic tiles. Dyes and Pigments, 127, 148–154. https://doi.org/10.1016/j.dyepig.2015.12.018

Weber, G., Chen, H.-L., Hinsch, E., Freitas, S., & Robinson, S. (2014). Pigments extracted from the wood-staining fungi Chlorociboria aeruginosa, Scytalidium cuboideum, and S. ganodermophthorum show potential for use as textile dyes. Coloration Technology, 130(6), 445–452. https://doi.org/10.1111/cote.12110

Hinsch, E. (2015). A Comparative Analysis of Extracted Fungal Pigments and Commercially Available Dyes for Colorizing Textiles. M.S. Thesis, Oregon State University. Oregon State University, Corvallis, Oregon.

Palomino-Agurto, M. E., Vega-Gutierrez, S. M., Chen, H.-L., & Robinson, S. C. (2017). Wood-rotting fungal pigments as colorant coatings on oil-based textile dyes. Coatings, 7, 10. https://doi.org/10.3390/coatings7100152

Robinson, S. C., Tudor, D., Zhang, W. R., Ng, S., & Cooper, P. A. (2014). Ability of three yellow pigment producing fungi to colour wood under controlled conditions. International Wood Products Journal, 5(2), 103–107. https://doi.org/10.1179/2042645313Y.0000000060

Saikawa, Y., Watanabe, T., Hashimoto, K., & Nakata, M. (2000). Absolute configuration and tautomeric structure of xylindein, a blue–green pigment of Chlorociboria species. Phytochemistry, 55(3), 237–240. https://doi.org/10.1016/S0031-9422(00)00282-X

Vega Gutierrez, S. M., Van Court, R. C., Stone, D. W., Konkler, M. J., Groth, E. N., & Robinson, S. C. (2018). Relationship between molarity and color in the crystal (‘Dramada’) Produced by Scytalidium cuboideum, in two solvents. Molecules, 23, 10. https://doi.org/10.3390/molecules23102581

Hinsch, E. M. (2015). A comparative analysis of extracted fungal pigments and commercially available dyes for colorizing textiles. Corvallis: Oregon State University.

Hinsch, E. M., & Robinson, S. C. (2016). Mechanical color reading of wood-staining fungal pigment textile dyes: an alternative method for determining colorfastness. Coatings, 6, 3. https://doi.org/10.3390/coatings6030025

Robinson, S. C., Weber, G., Hinsch, E., Vega Gutierrez, S. M., Pittis, L., & Freitas, S. (2014). Utilizing extracted fungal pigments for wood spalting: A comparison of induced fungal pigmentation to fungal dyeing. Journal of Coatings, 2014, 759073. https://doi.org/10.1155/2014/759073

Gutierrez, S. M. V., Hazell, K. K., Simonsen, J., & Robinson, S. C. (2018). Description of a naphthoquinonic crystal produced by the fungus Scytalidium cuboideum. Molecules, 23, 8. https://doi.org/10.3390/molecules23081905

Vega Gutierrez, S. M., He, Y., Cao, Y., Stone, D., Walsh, Z., Malhotra, R., et al. (2019). Feasibility and surface evaluation of the pigment from Scytalidium cuboideum for inkjet printing on textiles. Coatings, 9, 4. https://doi.org/10.3390/coatings9040266

Li, J., Li, Y., Song, X., & Chen, H. (2020). Photochromic printing and spectral properties of luminous polyester non-woven fabric. Surface Innovations, 8(3), 138–144

Güell, F., Martínez-Alanis, P. R., Khachadorian, S., Zamani, R. R., Franke, A., Hoffmann, A., et al. (2016). Spatially controlled growth of highly crystalline ZnO nanowires by an inkjet-printing catalyst-free method. Materials Research Express, 3(2), 025010. https://doi.org/10.1088/2053-1591/3/2/025010

Buanz, A. B. M., & Gaisford, S. (2017). Formation of highly metastable β glycine by confinement in inkjet printed droplets. Crystal Growth & Design, 17(3), 1245–1250. https://doi.org/10.1021/acs.cgd.6b01633

Hwang, H.-J., & Malhotra, R. (2019). Shape-tuned junction resistivity and self-damping dynamics in intense pulsed light sintering of silver nanostructure films. ACS Applied Materials & Interfaces, 11(3), 3536–3546. https://doi.org/10.1021/acsami.8b17644

Dexter, M., Bhandari, R., Chang, C. H., & Malhotra, R. (2017). Controlling processing temperatures and self-limiting behaviour in intense pulsed sintering by tailoring nanomaterial shape distribution. RSC Advances, 7(89), 56395–56405. https://doi.org/10.1039/C7RA11013H

Dexter, M., Gao, Z., Bansal, S., Chang, C.-H., & Malhotra, R. (2018). Temperature, crystalline phase and influence of substrate properties in intense pulsed light sintering of copper sulfide nanoparticle thin films. Scientific Reports, 8(1), 2201. https://doi.org/10.1038/s41598-018-20621-9

Dexter, M., Pfau, A., Gao, Z., Herman, G. S., Chang, C.-H., & Malhotra, R. (2018). Modeling nanoscale temperature gradients and conductivity evolution in pulsed light sintering of silver nanowire networks. Nanotechnology, 29(50), 505205. https://doi.org/10.1088/1361-6528/aae368

Hwang, H.-J., Devaraj, H., Yang, C., Gao, Z., Chang, C.-H., Lee, H., et al. (2018). Rapid pulsed light sintering of silver nanowires on woven polyester for personal thermal management with enhanced performance, durability and cost-effectiveness. Scientific Reports, 8(1), 17159. https://doi.org/10.1038/s41598-018-35650-7

Hwang, H.-J., Zeng, C., Pan, C., Dexter, M., Malhotra, R., & Chang, C.-H. (2020). Tuning electronic and photocatalytic properties in pulsed light synthesis of Cu2ZnSnS4 films from CuS-ZnS-SnS nanoparticles. Materials Research Bulletin, 122, 110645. https://doi.org/10.1016/j.materresbull.2019.110645

Devaraj, H., & Malhotra, R. (2019). Scalable forming and flash light sintering of polymer-supported interconnects for surface-conformal electronics. Journal of Manufacturing Science and Engineering, 141, 4. https://doi.org/10.1115/1.4042610

Jahangir, M. N., Cleeman, J., Hwang, H.-J., & Malhotra, R. (2019). Towards out-of-chamber damage-free fabrication of highly conductive nanoparticle-based circuits inside 3D printed thermally sensitive polymers. Additive Manufacturing, 30, 100886. https://doi.org/10.1016/j.addma.2019.100886

Christie, R. M. (2001). Colour chemistry. Cambridge: Royal Society of Chemistry.

Wang, C., Wang, L., Huang, Y., Meng, Y., Sun, G., Fan, Q., et al. (2017). Fabrication of reactive pigment composite particles for blue-light curable inkjet printing of textiles. RSC Advances, 7(57), 36175–36184. https://doi.org/10.1039/C7RA04576J

Gutierrez, P. V., Almushardi, B., Huber, M., Andersen, C., Van Court, R. C., & Robinson, S. C. (2020). Expanding the spalting palette: Developing yellow, purple, and green pigments from Scytalidium ganodermophthorum. International Wood Products Journal. https://doi.org/10.1080/20426445.2020.1780543

Acknowledgements

The authors acknowledge the support provided by the Walmart Manufacturing Innovation Fund, the National Science Foundation Major Research Instrumentation (MRI) Program # 1040588, and the VF corporation.

Funding

This work was supported by the Walmart Manufacturing Innovation Fund and the National Science Foundation Major Research Instrumentation (MRI) Program # 1040588.

Author information

Authors and Affiliations

Contributions

RM, C-HC, SCR and H-LC originated the idea and planned the work. SMVG performed the biopigment exraction. YH and YC performed the inkjet printing, SEM, colorimetry, and TEM. H-JH and HD performed the humidity and temperature testing. SL performed the wash testing. All authors contributed towards the writing of the manuscript. The authors acknowledge Alvin Chang for his assistance in writing the paper and VF Corporation for providing the cotton fabrics.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

He, Y., Cao, Y., Hwang, Hj. et al. Inkjet Printing and In-Situ Crystallization of Biopigments for Eco-Friendly and Energy-Efficient Fabric Coloration. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 941–953 (2022). https://doi.org/10.1007/s40684-021-00360-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00360-5