Abstract

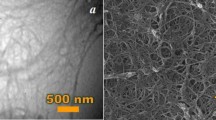

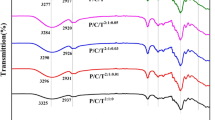

Concerns about environmental problems have led to the development of biodegradable packaging. Food wastes as a byproduct could be a good source for biopolymers. This study aimed to describe the physical and antimicrobial features of nano biocomposite films based on orange waste powder (OWP) with different concentrations of nettle essential oil (NEO) (1.5 and 3%) as an antibacterial agent and cellulose nanofiber (CNF) (3 and 6%) as a structural reinforcement. Thus, Field emission scanning electron microscopy (FE-SEM), Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), and differential scanning calorimetry analysis (DSC) were performed. Further, tensile strength, elongation at break, water vapor permeability, and antimicrobial properties were investigated. As a result, the addition of CNF improved the tensile strength and water barrier properties of the samples. Compared to the control film, adding NEO (3%) decreased the tensile strength but increased water vapor permeability and melting temperature. Moreover, the OWP-based film samples had an antimicrobial effect against five foodborne pathogens; this effect was increased considerably by enhancing the NEO concentration. In this regard, the maximum and minimum susceptibility was related to the Staphylococcus aureus and Salmonella enterica, respectively. In conclusion, orange waste could be used to produce an active film with improved physicomechanical and antibacterial properties by incorporating CNF and NEO.

Similar content being viewed by others

References

Dashipour A, Razavilar V, Hosseini H et al (2015) Antioxidant and antimicrobial carboxymethyl cellulose films containing Zataria multiflora essential oil. Int J Biol Macromol 72:606–613. https://doi.org/10.1016/j.ijbiomac.2014.09.006

Soofi M, Alizadeh A, Hamishehkar H et al (2021) Preparation of nanobiocomposite film based on lemon waste containing cellulose nanofiber and savory essential oil: a new biodegradable active packaging system. Int J Biol Macromol 169:352–361. https://doi.org/10.1016/j.ijbiomac.2020.12.114

Jouki M, Yazdi FT, Mortazavi SA, Koocheki A (2014) Quince seed mucilage films incorporated with oregano essential oil: physical, thermal, barrier, antioxidant and antibacterial properties. Food Hydrocoll 36:9–19. https://doi.org/10.1016/j.foodhyd.2013.08.030

Karimi N, Alizadeh A, Almasi H, Hanifian S (2020) Preparation and characterization of whey protein isolate/polydextrose-based nanocomposite film incorporated with cellulose nanofiber and L. plantarum: a new probiotic active packaging system. LWT. https://doi.org/10.1016/j.lwt.2019.108978

Viana RM, Sá NMSM, Barros MO et al (2018) Nanofibrillated bacterial cellulose and pectin edible films added with fruit purees. Carbohydr Polym 196:27–32. https://doi.org/10.1016/j.carbpol.2018.05.017

Zabihollahi N, Alizadeh A, Almasi H et al (2020) Development and characterization of carboxymethyl cellulose based probiotic nanocomposite film containing cellulose nanofiber and inulin for chicken fillet shelf life extension. Int J Biol Macromol 160:409–417

Tulamandi S, Rangarajan V, Rizvi SSH et al (2016) A biodegradable and edible packaging film based on papaya puree, gelatin, and defatted soy protein. Food Packag Shelf Life 10:60–71. https://doi.org/10.1016/j.fpsl.2016.10.007

Mohebbi M, Ansarifar E, Hasanpour N, Amiryousefi MR (2012) Suitability of Aloe vera and gum tragacanth as edible coatings for extending the shelf life of button mushroom. Food Bioprocess Technol 5:3193–3202

Razavi SMA, Amini AM, Zahedi Y (2015) Characterisation of a new biodegradable edible film based on sage seed gum: influence of plasticiser type and concentration. Food Hydrocoll 43:290–298

Seyedi S, Koocheki A, Mohebbi M, Zahedi Y (2014) Lepidium perfoliatum seed gum: a new source of carbohydrate to make a biodegradable film. Carbohydr Polym 101:349–358

Wang X, Sun X, Liu H et al (2010) Food and Bioproducts Processing Barrier and mechanical properties of carrot puree films. Food Bioprod Process 89:149–156. https://doi.org/10.1016/j.fbp.2010.03.012

Bátori V, Jabbari M, Åkesson D et al (2017) Production of pectin-cellulose biofilms: a new approach for citrus waste recycling. Int J Polym Sci. https://doi.org/10.1155/2017/9732329

McKay S, Sawant P, Fehlberg J, Almenar E (2021) Antimicrobial activity of orange juice processing waste in powder form and its suitability to produce antimicrobial packaging. Waste Manag 120:230–239

FAO (2018) Food and Agriculture Organization of the United Nations Cropping Database. FAO, Rome

Azeredo HMC, Mattoso LHC, Wood D et al (2009) Nanocomposite edible films from mango puree reinforced with cellulose nanofibers. J Food Sci 74:31–35. https://doi.org/10.1111/j.1750-3841.2009.01186.x

Oun AA, Rhim JW (2015) Preparation and characterization of sodium carboxymethyl cellulose/cotton linter cellulose nanofibril composite films. Carbohydr Polym 127:101–109. https://doi.org/10.1016/j.carbpol.2015.03.073

Sherafatkhah Azari S, Alizadeh A, Roufegarinejad L et al (2020) Preparation and characterization of gelatin/β-glucan nanocomposite film incorporated with ZnO nanoparticles as an active food packaging system. J Polym Environ. https://doi.org/10.1007/s10924-020-01950-1

Esmaeili H, Cheraghi N, Khanjari A et al (2020) Incorporation of nanoencapsulated garlic essential oil into edible films: a novel approach for extending shelf life of vacuum-packed sausages. Meat Sci. https://doi.org/10.1016/j.meatsci.2020.108135

Gül S, Emirci B, Başer KH et al (2012) Chemical composition and in vitro cytotoxic, genotoxic effects of essential oil from Urtica dioica L. Bull Environ Contam Toxicol 88:666–671. https://doi.org/10.1007/s00128-012-0535-9

Bassania A, Montesb S, Jubeteb E et al (2019) Incorporation of waste orange peels extracts into PLA films. Chem Eng. https://doi.org/10.3303/CET1974178

Ghadetaj A, Almasi H, Mehryar L (2018) Development and characterization of whey protein isolate active films containing nanoemulsions of Grammosciadium ptrocarpum Bioss. essential oil. Food Packag Shelf Life 16:31–40. https://doi.org/10.1016/j.fpsl.2018.01.012

Nisar T, Wang ZC, Yang X et al (2018) Characterization of citrus pectin films integrated with clove bud essential oil: physical, thermal, barrier, antioxidant and antibacterial properties. Int J Biol Macromol 106:670–680. https://doi.org/10.1016/j.ijbiomac.2017.08.068

Šešlija S, Nešić A, Ružić J et al (2018) Edible blend films of pectin and poly(ethylene glycol): preparation and physico-chemical evaluation. Food Hydrocoll 77:494–501. https://doi.org/10.1016/j.foodhyd.2017.10.027

Szymanska-Chargot M, Zdunek A (2013) Use of FT-IR spectra and PCA to the bulk characterization of cell wall residues of fruits and vegetables along a fraction process. Food Biophys 8:29–42. https://doi.org/10.1007/s11483-012-9279-7

Rajinipriya M, Nagalakshmaiah M, Robert M, Elkoun S (2018) Homogenous and transparent nanocellulosic films from carrot. Ind Crops Prod 118:53–64. https://doi.org/10.1016/j.indcrop.2018.02.076

Zykwinska AW, Ralet MCJ, Garnier CD, Thibault JFJ (2005) Evidence for in vitro binding of pectin side chains to cellulose. Plant Physiol 139:397–407. https://doi.org/10.1104/pp.105.065912

Shahmohammadi Jebel F, Almasi H (2016) Morphological, physical, antimicrobial and release properties of ZnO nanoparticles-loaded bacterial cellulose films. Carbohydr Polym 149:8–19. https://doi.org/10.1016/j.carbpol.2016.04.089

Molaee-Aghaee E, Kamkar A, Akhondzadeh-Basti A, Khanjari A (2021) Antimicrobial effect of garlic essential oil (Allium sativum L.) in combination with chitosan biodegradable coating films. Int J Food Microbiol 342:109071

Mahardika M, Abral H, Kasim A et al (2019) Properties of cellulose nanofiber/bengkoang starch bionanocomposites: effect of fiber loading. LWT 116:108554

Fernandes SCM, Oliveira L, Freire CSR et al (2009) Novel transparent nanocomposite films based on chitosan and bacterial cellulose. Green Chem 11:2023–2029. https://doi.org/10.1039/b919112g

Atef M, Rezaei M, Behrooz R (2014) Preparation and characterization agar-based nanocomposite film reinforced by nanocrystalline cellulose. Int J Biol Macromol 70:537–544. https://doi.org/10.1016/j.ijbiomac.2014.07.013

Sahraee S, Milani JM, Ghanbarzadeh B, Hamishehkar H (2017) Effect of corn oil on physical, thermal, and antifungal properties of gelatin-based nanocomposite films containing nano chitin. LWT Food Sci Technol 76:33–39. https://doi.org/10.1016/j.lwt.2016.10.028

Pelissari FM, Andrade-Mahecha MM, do Sobral PJA, Menegalli FC (2017) Nanocomposites based on banana starch reinforced with cellulose nanofibers isolated from banana peels. J Colloid Interface Sci 505:154–167. https://doi.org/10.1016/j.jcis.2017.05.106

Petersson L, Oksman K (2006) Biopolymer based nanocomposites: comparing layered silicates and microcrystalline cellulose as nanoreinforcement. Compos Sci Technol 66:2187–2196. https://doi.org/10.1016/j.compscitech.2005.12.010

Ghanbarzadeh B, Almasi H, Entezami AA (2010) Physical properties of edible modified starch/carboxymethyl cellulose films. Innov Food Sci Emerg Technol 11:697–702. https://doi.org/10.1016/j.ifset.2010.06.001

Ghanbarzadeh B, Almasi H (2011) Physical properties of edible emulsified films based on carboxymethyl cellulose and oleic acid. Int J Biol Macromol 48:44–49. https://doi.org/10.1016/j.ijbiomac.2010.09.014

Ghanbarzadeh B, Oromiehi AR (2009) Thermal and mechanical behavior of laminated protein films. J Food Eng 90:517–524. https://doi.org/10.1016/j.jfoodeng.2008.07.018

Huq T, Salmieri S, Khan A et al (2012) Nanocrystalline cellulose (NCC) reinforced alginate based biodegradable nanocomposite film. Carbohydr Polym 90:1757–1763. https://doi.org/10.1016/j.carbpol.2012.07.065

Shankar S, Rhim JW (2016) Preparation of nanocellulose from micro-crystalline cellulose: the effect on the performance and properties of agar-based composite films. Carbohydr Polym 135:18–26. https://doi.org/10.1016/j.carbpol.2015.08.082

Shojaee-Aliabadi S, Hosseini H, Mohammadifar MA et al (2013) Characterization of antioxidant-antimicrobial κ-carrageenan films containing Satureja hortensis essential oil. Int J Biol Macromol 52:116–124. https://doi.org/10.1016/j.ijbiomac.2012.08.026

Ramos M, Jiménez A, Peltzer M, Garrigós MC (2012) Characterization and antimicrobial activity studies of polypropylene films with carvacrol and thymol for active packaging. J Food Eng 109:513–519. https://doi.org/10.1016/j.jfoodeng.2011.10.031

Fabra MJ, Talens P, Chiralt A (2008) Tensile properties and water vapor permeability of sodium caseinate films containing oleic acid-beeswax mixtures. J Food Eng 85:393–400. https://doi.org/10.1016/j.jfoodeng.2007.07.022

Jamróz E, Juszczak L, Kucharek M (2018) Investigation of the physical properties, antioxidant and antimicrobial activity of ternary potato starch-furcellaran-gelatin films incorporated with lavender essential oil. Int J Biol Macromol 114:1094–1101. https://doi.org/10.1016/j.ijbiomac.2018.04.014

Ahmad M, Benjakul S, Prodpran T, Agustini TW (2012) Physico-mechanical and antimicrobial properties of gelatin film from the skin of unicorn leatherjacket incorporated with essential oils. Food Hydrocoll 28:189–199. https://doi.org/10.1016/j.foodhyd.2011.12.003

Hosseini MH, Razavi SH, Mousavi MA (2009) Antimicrobial, physical and mechanical properties of chitosan-based films incorporated with thyme, clove and cinnamon essential oils. J food Process Preserv 33:727–743

Espinosa-Pardo FA, Nakajima VM, Macedo GA et al (2017) Extraction of phenolic compounds from dry and fermented orange pomace using supercritical CO2 and cosolvents. Food Bioprod Process 101:1–10. https://doi.org/10.1016/j.fbp.2016.10.002

Hosseini SF, Rezaei M, Zandi M, Farahmandghavi F (2015) Bio-based composite edible films containing Origanum vulgare L. essential oil. Ind Crops Prod 67:403–413. https://doi.org/10.1016/j.indcrop.2015.01.062

Shojaee-Aliabadi S, Mohammadifar MA, Hosseini H et al (2014) Characterization of nanobiocomposite kappa-carrageenan film with Zataria multiflora essential oil and nanoclay. Int J Biol Macromol 69:282–289. https://doi.org/10.1016/j.ijbiomac.2014.05.015

Acknowledgements

The authors gratefully acknowledge the supports of the Islamic Azad University, Tabriz Branch. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mousavi Kalajahi, S., Alizadeh, A., Hamishehkar, H. et al. Orange Juice Processing Waste as a Biopolymer Base for Biodegradable Film Formation Reinforced with Cellulose Nanofiber and Activated with Nettle Essential Oil. J Polym Environ 30, 258–269 (2022). https://doi.org/10.1007/s10924-021-02195-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02195-2