Abstract

In-plane uniaxial tension of AZ31 magnesium alloy sheet with non-basal texture has been conducted in order to demonstrate the effects of loading direction on the microstructure evolution and mechanical properties at ambient temperature. Loading axes are chosen to be along five directions distributed between rolling direction (RD) and transverse direction (TD), allowing various activities in involved slip and twinning modes to take place. As for twinning modes, electron backscattered diffraction observations confirm that the contribution of \({{\{ 10\overline{1}1\} }}\) compression twinning is minimal to the plastic deformation of all deformed samples. By comparison, \({{\{ 10\overline{1}2\} }}\) extension twinning (ET) not only serves as an important carrier on sustaining and accommodating plastic strain but also contributes to the emergence of TD-component texture with the progression of plastic strain. In terms of slip modes, analysis on Schmid factor demonstrates that the increasing tilted angle between loading direction and RD of sheet is unfavorable to the activation of basal <a> slip, whereas it contributes to the activation of prismatic <a> slip. These observations consequently explain the increasing tendency of 0.2% proof yield stress. Moreover, the activations of basal <a> slip and \({{\{ 10\overline{1}2\} }}\) ET collectively contribute to the concentration of two tilted basal poles toward normal direction. With increasing angle between loading direction and RD, the activations of basal <a> slip and \({{\{ 10\overline{1}2\} }}\) ET are gradually weakened. This leads to a weakening tendency about concentration of two tilted basal poles, a generally increasing tendency about Lankford value (r-value) and a generally decreasing tendency about strain-hardening exponent (n-value).

Similar content being viewed by others

Change history

27 October 2023

A Correction to this paper has been published: https://doi.org/10.1007/s40195-023-01614-8

References

J. Hirsch, T. Alsamman, Acta Mater. 61, 818 (2013)

B.Q. Xiao, J.F. Song, H. Zhao, A.T. Tang, Q. Liu, B. Jiang, S.T. Dou, F.S. Pan, Acta Metall. Sin. Engl. Lett. 34, 227 (2021)

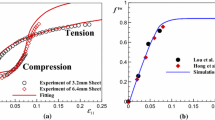

F. Kabirian, A.S. Khan, T. Gnaupelherlod, Int. J. Plast. 68, 1 (2015)

J.L. Zhang, H. Liu, Y.L. Xie, G.S. Huang, X. Chen, B. Jiang, A.T. Tang, F.S. Pan, Acta Metall. Sin. Engl. Lett. 33, 1487 (2020)

C.H. Ma, F.S. Pan, D.F. Zhang, A.T. Tang, Z.W. Lu, Acta Metall. Sin. Engl. Lett. 34, 278 (2021)

L. Lu, T. Liu, Y. Chen, Z. Wang, Mater. Charact. 67, 93 (2012)

J. Suh, J. Victoriahernandez, D. Letzig, R. Golle, S. Yi, J. Bohlen, W. Volk, J. Mater. Process. Technol. 217, 286 (2015)

R.B. Figueiredo, S. Sabbaghianrad, A. Giwa, J.R. Greer, T.G. Langdon, Acta Mater. 122, 322 (2017)

F. Guo, D. Zhang, X. Fan, J. Li, L. Jiang, F. Pan, Mater. Sci. Eng. A 655, 92 (2016)

J. Tu, T. Zhou, L. Liu, L. Shi, H. Li, D. Song, B. Song, M. Yang, Q. Chen, F.S. Pan, J. Alloys Compd. 768, 598 (2018)

D. Song, T. Zhou, J. Tu, L. Shi, B. Song, L. Hu, M. Yang, Q. Chen, L. Lu, J. Mater. Process. Technol. 259, 380 (2018)

X. Zhang, Y. Cheng, J. Alloys Compd. 622, 1105 (2015)

J. Ma, X. Yang, H. Sun, Q. Huo, J. Wang, J. Qin, Mater. Sci. Eng. A 584, 156 (2013)

T. Ebeling, C. Hartig, T. Laser, R. Bormann, Mater. Sci. Eng. A 527, 272 (2009)

S.R. Agnew, C.N. Tome, D.W. Brown, T.M. Holden, S.C. Vogel, Scr. Mater. 48, 1003 (2003)

Y. Chen, L. Hu, L. Shi, T. Zhou, J. Tu, Q. Chen, M. Yang, Mater. Sci. Eng. A 769, 138497 (2020)

R. Hielscher, H. Schaeben, J. Appl. Crystallogr. 41, 1024 (2008)

Y.K. Wu, Z. Liu, X. Qin, C. Wang, L. Zhou, J. Alloys Compd. 795, 370 (2019)

R. Badji, T. Chauveau, B. Bacroix, Mater. Sci. Eng. A 575, 94 (2013)

L. Jiang, J.J. Jonas, R.K. Mishra, A.A. Luo, A.K. Sachdev, S. Godet, Acta Mater. 55, 3899 (2007)

B. Song, R. Xin, N. Guo, Z. Chen, X. Yang, Q. Liu, Mater. Lett. 176, 147 (2016)

T. Zhou, Z. Yang, D. Hu, T. Feng, M. Yang, X. Zhai, J. Alloys Compd. 650, 436 (2015)

X. Huang, K. Suzuki, A. Watazu, I. Shigematsu, N. Saito, J. Alloys Compd. 470, 263 (2009)

A. Fernández, A. Jérusalem, I. Gutiérrez-Urrutia, M.T. Pérez-Prado, Acta Mater. 61, 7679 (2013)

A. Chapuis, Z.Q. Wang, Q. Liu, Mater. Sci. Eng. A 655, 244 (2016)

A. Chapuis, Q. Liu, Comput. Mater. Sci. 97, 121 (2015)

J. Zhao, B. Jiang, A. Tang, Y. Chai, B. Liu, H. Sheng, T. Yang, G. Huang, D. Zhang, F.S. Pan, Mater. Charact. 159, 110041 (2020)

Y. Lian, H. Li, T. Zhou, M. Yang, J. Zhang, Metals 9, 41 (2019)

A.V. Pandey, F. Kabirian, J. Hwang, S. Choi, A.S. Khan, Int. J. Plast. 68, 111 (2015)

S.R. Agnew, M.H. Yoo, C.N. Tome, Acta Mater. 49, 4277 (2001)

X. Huang, K. Suzuki, N. Saito, Scr. Mater. 60, 651 (2009)

X. Huang, K. Suzuki, A. Watazu, I. Shigematsu, N. Saito, Mater. Sci. Eng. A 488, 214 (2008)

J.A. del Valle, F. Carreño, O.A. Ruano, Acta Mater. 54, 4247 (2006)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51805064, 51822509, 51701034), the Scientific and Technological Research Program of Chongqing Municipal Education Commission (Grant No. KJQN201801137), the Basic and Advanced Research Project of Chongqing Science and Technology Commission (Grant Nos. cstc2017jcyjAX0062, cstc2018jcyjAX0035), the Chongqing University Key Laboratory of Micro/Nano Materials Engineering and Technology (Grant No. KFJJ2003).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, L., Li, M., Chen, Q. et al. Dependence of Microstructure Evolution and Mechanical Properties on Loading Direction for AZ31 Magnesium Alloy Sheet with Non-basal Texture During In-Plane Uniaxial Tension. Acta Metall. Sin. (Engl. Lett.) 35, 223–234 (2022). https://doi.org/10.1007/s40195-021-01246-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01246-w