Abstract

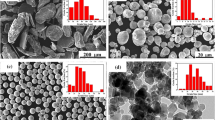

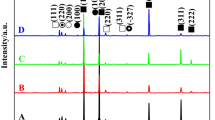

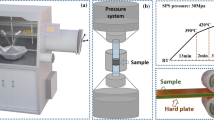

15 vol.% SiC/Al-6.5Zn-2.8 Mg-1.7Cu (wt%) composites with varying particle sizes (3.5, 7.0, 14 and 20 μm), i.e., C-3.5, C-7.0, C-14, and C-20, respectively, were fabricated by powder metallurgy (PM) method and subjected to microstructural examination. The effect of particle size on mechanical properties and fracture behaviors of the T6-treated composites was revealed and analyzed in detail. Element distribution and precipitates variations in the composites with varying particle sizes were emphatically considered. Results indicated that both tensile strength and plasticity of the T6-treated composites increased first and then decreased with particle size decreasing. The C-7.0 composite simultaneously exhibited the highest ultimate tensile strength (UTS) of 686 MPa and best elongation (El.) of 3.1%. The smaller-sized SiC particle would introduce more oxide impurities, which would react with the alloying element in the matrix to cause Mg segregation and depletion. According to strengthening mechanism analysis, the weakening of precipitation strengthening in the T6-treated C-3.5 composite was the main cause of the lower tensile strength. Additionally, the larger SiC particle, the more likely to fracture, especially in the composites with high yield strength. For the T6-treated C-20 composites, more than 75% SiC particles were broken up, resulting in the lowest plasticity. As decreasing particle size, the fracture behaviors of the T6-treated composites would change from particle fracture to matrix alloy fracture gradually.

Similar content being viewed by others

References

C. Wang, B.B. Wang, D. Wang, P. Xue, Q.Z. Wang, B.L. Xiao, L.Q. Chen, Z.Y. Ma, Acta Metall. Sin. -Engl. Lett. 32, 677 (2019)

J. Nie, J. Fan, S. Zhang, S. Wei, T. Zuo, Z. Ma, Z. Xiang, Acta Metall. Sin. -Engl. Lett. 27, 875 (2014)

J. Hu, G.H. Wu, Q. Zhang, H.S. Gou, Compos. Part B 66, 400 (2014)

Z.Y. Liu, Q.Z. Wang, B.L. Xiao, Z.Y. Ma, Compos. Part A 41, 1686 (2010)

S.Z. Zhu, G.N. Ma, D. Wang, B.L. Xiao, Z.Y. Ma, Mater. Sci. Eng. A 767, 138422 (2019)

J.F. Zhang, X.X. Zhang, Q.Z. Wang, B.L. Xiao, Z.Y. Ma, J. Mater. Sci. Technol. 34, 627 (2018)

T.W. Lu, W.P. Chen, W.Y. Xu, P. Wang, M.D. Mao, Y.X. Liu, Z.Q. Fu, Mater. Charact. 136, 264 (2018)

G.N. Ma, D. Wang, Z.Y. Liu, S. Bi, Y.N. Zan, B.L. Xiao, Z.Y. Ma, Acta Metall. Sin. 55, 1319 (2019)

W.H. Yuan, J. Zhang, C.C. Zhang, Z.H. Chen, J. Mater. Process. Technol. 209, 3251 (2009)

X. Gao, X.X. Zhang, L. Geng, Mater. Sci. Eng. A 740, 353 (2019)

J.F. Jiang, Y. Wang, X. Nie, G.F. Xiao, Mater. Des. 96, 36 (2016)

Y.H. Jiao, J.F. Zhu, X.L. Li, F. Wang, X. Zhao, C.J. Shi, W. Abdul, B. Lu, Ceram. Int. 46, 17675 (2020)

G. Xue, L.D. Ke, H.L. Liao, C.P. Chen, H.H. Zhu, J. Alloy. Compd. 845, 18813 (2020)

C. Sun, M. Song, Z.W. Wang, Y.H. He, J. Mater. Eng. Perform. 20, 1606 (2011)

T.K. Ye, Y.X. Xu, J. Ren, Mater. Sci. Eng. A 753, 146 (2019)

H. Lee, J.H. Choi, M.C. Jo, D. Lee, S. Shin, I. Jo, S.K. Lee, S. Lee, Mater. Sci. Eng. A 738, 412 (2018)

X.L. Guo, Q. Guo, J.H. Nie, Z.Y. Liu, Z.Q. Li, G.L. Fan, D.B. Xiong, Y.S. Su, J.Z. Fan, D. Zhang, Mater. Sci. Eng. A 711, 643 (2018)

Y.N. Zan, Y.T. Zhou, Z.Y. Liu, G.N. Ma, D. Wang, Q.Z. Wang, W.G. Wang, B.L. Xiao, Z.Y. Ma, Mater. Des. 166, 107629 (2019)

J.C. Shao, B.L. Xiao, Q.Z. Wang, Z.Y. Ma, K. Yang, Compos. Sci. Technol. 71, 39 (2011)

Z. Xiang, J. Nie, S. Wei, T. Zuo, Z. Ma, J. Fan, Chin. J. Rare Metals 39, 998 (2015)

G.N. Ma, D. Wang, Z.Y. Liu, B.L. Xiao, Z.Y. Ma, Mater. Charact. 158, 109966 (2019)

D. Xu, Z. Li, G. Wang, X. Li, X. Lv, Ya. Zhang, Y. Fan, B. Xiong, Mater. Charact. 131, 285 (2017)

H. Li, F. Cao, S. Guo, Y. Jia, D. Zhang, Z. Liu, P. Wang, S. Scudino, J. Sun, J. Alloy. Compd. 719, 89 (2017)

M.M. Sharma, M.F. Amateau, T.J. Eden, Mater. Sci. Eng. A 424, 87 (2006)

J.G. Zhao, Z.Y. Liu, S. Bai, D.P. Zeng, L. Luo, J. Wang, J. Alloy. Compd. 829, 154469 (2020)

Y. Li, Y.L. Deng, S.T. Fan, X.B. Guo, K.D. Jiang, Z. Zhang, L. Sun, J. Alloy. Compd. 829, 154612 (2020)

K. Zhao, Z.Y. Liu, B.L. Xiao, D.R. Ni, Z.Y. Ma, Acta Metall. Sin. -Engl. Lett. 31, 134 (2018)

B.W. Xiong, Z.F. Xu, Q.S. Yan, B.P. Lu, C.C. Cai, J. Alloy. Compd. 509, 1187 (2011)

Z.P. Luo, Acta Mater. 54, 47 (2006)

Z.Y. Huang, X.X. Zhang, C. Yang, B.L. Xiao, Z.Y. Ma, J. Alloy. Compd. 743, 87 (2018)

K. Tesař, H. Somekawa, A. Singh, J. Alloy. Compd. 849, 156340 (2020)

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Acta Mater. 62, 141 (2014)

X. Xu, J. Zheng, Z. Li, R. Luo, B. Chen, Mater. Sci. Eng. A 691, 60 (2017)

W.X. Shu, L.G. Hou, C. Zhang, F. Zhang, J.C. Liu, J.T. Liu, L.Z. Zhuang, J.S. Zhang, Mater. Sci. Eng. A 657, 269 (2016)

Z. Zhang, D.L. Chen, Scr. Mater. 54, 1321 (2006)

H. Wen, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, Acta Mater. 61, 2769 (2013)

J.Y. Zhang, B. Wang, H. Wang, Mater. Charact. 162, 110205 (2020)

H.D. Fan, S. Aubry, A. Arsenlis, J.A. El-Awady, Scr. Mater. 112, 50 (2016)

O.B. Bembalge, S.K. Panigrahi, J. Alloy. Compd. 766, 355 (2018)

R.X. Liu, C.D. Wu, J. Zhang, G.Q. Luo, Q. Shen, L.M. Zhang, J. Alloy. Compd. 748, 737 (2018)

Acknowledgements

This work was financially supported by the National Key R & D Program of China (No. 2017YFB0703104) and the National Natural Science Foundation of China (Grant Nos. 51771193 and 51931009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Ma, G., Wang, D., Xiao, B. et al. Effect of Particle Size on Mechanical Properties and Fracture Behaviors of Age-Hardening SiC/Al–Zn–Mg–Cu Composites. Acta Metall. Sin. (Engl. Lett.) 34, 1447–1459 (2021). https://doi.org/10.1007/s40195-021-01254-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01254-w