Abstract

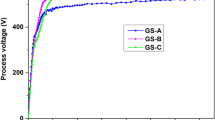

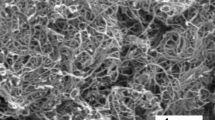

Surface modification of high-strength aluminium alloy 7075-T6 by plasma electrolytic oxidation (PEO) and type II hard anodization (HA) is presented in the current work. PEO-based ceramic oxide coatings were fabricated by employing an alternating current (AC) power source with a current density of 300 mA/cm2. The concentration effect of electrolytes on the alumina coatings was investigated and optimized comprehensively. Three separate aqueous electrolytes with 1:3, 1:1 and 3:1 proportions of sodium silicate (Na2SiO3) and potassium hydroxide (KOH) were utilized to evaluate optimum electrolyte concentration for obtaining desired AC-PEO coatings. X-ray diffraction (XRD) was utilized to investigate the phase composition of the coatings. Field emission scanning electron microscopy (FESEM) was employed to investigate the surface and cross-sectional characteristics of oxide coatings. Scratch testing was used to assess the oxide coatings' adhesion ability, and potentiodynamic polarization (PDP) was utilized to assess the coatings' corrosion behaviour in a 3.5 wt% aqueous NaCl solution. Among the AC-PEO and HA coatings, the AC-PEO specimen fabricated with equal ratios of sodium silicate and KOH concentration (Na2SiO3:KOH 1:1) showed excellent adhesion strength (critical load, Lc = 41.5 N) along with the remarkable corrosion resistance (corrosion current density, icorr = 5.63 × 10–6 mA/cm2).

Similar content being viewed by others

References

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, and Miller W S, Mater Sci Eng A 280 (2000) 102.

Eswara Prasad E, and Wanhill R J H, Aerospace Materials and Material Technologies Vol 1: Aerospace Materials, IIM Series, Springer Singapore (2017).

Yu M, Dong H, and Shi H, Appl Surf Sci 479 (2019) 105-113.

Agureev L, Savushkina S, Ashmarin A, Borisov A, Apelfeld A, Anikin K, Tkachenko N, Gerasimov M, Shcherbakov A, Ignatenko V, and Bogdashkina N, Metals 8 (2018) 459.

Arunnellaiappan T, Kishore Babu N, Rama Krishna L, and Rameshbabu N, Surf Coat Technol 280 (2015) 136.

Wang R, Wang L, He C, Lu M, and Sun L, Surf Coat Technol 360 (2019) 369.

Abdel-Gawad S A, Osman W M, and Fekry A M, Surf Interfaces 14 (2019) 314.

Stergioudi F, Vogiatzis C A, Gkrekos K, Michailidis N, and Skolianos S M, Corros Sci 91 (2015) 151.

Thiemea M, Strellera F, Simonb F, Frenzelb R, and White A J, Appl Surf Sci 283 (2013) 1041.

Gonzalez E, Vejar N, Solis R, Muñoz L, Victoria Encinas M, and Paez M, Sol–Gel Method- Design and Synthesis of New Materials with Interesting Physical, Chemical and Biological Properties, (ed) Aguilar G V, Intech open, London (2019) p 75.

Lawal J, Kiryukhantsev-Korneev P, Matthews A, and Leyland A, Surf Coat Technol 310 (2017) 59.

Assadi H, Kreye H, Gärtner F, and Klassen T, Acta Mater 116 (2016) 382.

Tesar T, Musalek R, Medricky J, Kotlana J, Lukac F, Pala Z, Ctibor P, Chraska T, Houdkova S, Rimal V, and Curry N, Surf Coat Technol 325 (2017) 277.

Gökhan Demira A, and Alberto Biffi C, J Manuf Process 37 (2019) 362.

Arunnellaiappan T, Ashfaq M, Rama Krishna L, and Rameshbabu N, Ceram Int 42(2016) 5897.

Sreekanth D, and Rameshbabu N, Mater Lett 68 (2012).

Arun S, Hariprasad S, Saikiran A, Ravisankar B, Parfenov E V, Mukaeva V R, and Rameshbabu N, Surf Coat Technol 363 (2019) 301.

Sharma A, Jang Y J, and Jung J P, J Mater Eng Perform 26 (2017) 5032.

Mohitfar S H, Mahdavi S, Etminanfar M R, and Khalil-Allafi J, J Alloys Compd 842 (2020) 155988.

Lerner L M, Trans Inst Met Finish 88 (2010).

Hariprasad S, Gowtham S, Arun S, Ashok M, and Rameshbabu N, J Alloys Compd 722 (2017) 698.

Sieber M, Mehner T, Dietrich D, Alisch G, Nickel D, Meyer D, Scharf I, and Lampke T, Surf Coat Technol 240 (2014) 96.

Walsh F C, Low C T J, Wood R J K, Stevens K T, Archer J, Poeton A R, and Ryder A, Trans Inst Met Finish 87 (2009) 122.

Hussein R O, and Northwood D O, in Developments in Corrosion Protection, (ed) Aliofkhazraei M, Intech open, Croatia (2014) p 201.

Mohedano M, Lu X, Matykina E, Blawert C, Arrabal R, and Zheludkevich M L, Plasma Electrolytic Oxidation (PEO) of Metals and Alloys (2018), p 423.

Saikiran A, Hariprasad S, Manojkumar P, Rama Krishna L, and Rameshbabu N, Surf Coat Technol 394 (2014) 125888.

Manojkumar P, Lokeshkumar E, Saikiran A, Govardhanan B, Ashok M, and Rameshbabu N, J Alloys Compd 825 (2020) 154092.

Yang Z, Wu Y K, Zhang X Z, Wang D D, Liu X T, Wu G R, Li D L, Yu S X, and Shen D J, Surf Interfaces 16 (2019) 199.

Babaei K, Fattah-alhosseini A, and Molaei M, Surf Interfaces 21 (2020) 100677.

Hariprasad S, Saikiran A, Premchand C, Rama Krishna L, and Rameshbabu N, J Magnes Alloy (2020, in press).

Li Q, Liang J, Wang Q, in Modern Surface Engineering Treatments, (ed) Aliofkhazraei M, Intech open, Croatia (2013), p 75.

Santosh Prasad S, Etsushi T, Yoshitaka A, and Hiroki H, Corros Sci 55 (2012) 90.

Pillai A M, Rajendra A, and Sharma A K, J Appl Electrochem 48 (2018) 543.

Khan R H U, Yerokhin A, Li X, Dong H, and Matthews A, Surf Coat Technol 205 (2010) 1679.

Jiang B L, and Wang Y M, in Surface Engineering of Light Alloys: Aluminium, Magnesium and Titanium Alloys, (ed) Dong H, Woodhead Publishing (2010) p 110.

Yerokhin A L, Shatrov A, Samsonov V, Shashkov P, Pilkington A, Leyland A, and Matthews A, Surf Coat Technol 199 (2005) 150.

Ghafaripoor M, Raeissia K, Santamaria M, and Hakimizad A, Surf Coat Technol 349 (2018) 470.

Kwolek P, Krupa K, Obłoj A, Kocurek P, Wierzbinska M, and Sieniawski J, J Mater Eng Perform 27 (2018) 3268.

Rama Krishna L, Sudha Purnima A, and Sundararajan G, Wear 261 (2006) 1095.

Alexandre Becerik D, Ayday A, Cenk Kumruoglu L, Can Kurnaz S, and Ozel A, J Mater Eng Perform 21 (2012) 1426.

Fattah-Alhosseini A, Vakili-Azghandi M, and Keshavarz M K, Acta Metall Sin (Engl Lett) 29 (2016) 274.

Yerokhin A L, Snizhko L O, Gurevina N L, Leyland A, Pilkington A, and Matthews A, J Phys D Appl Phys 36 (2003) 2110.

Ikonopisov S, Girginov A, and Machkova M, Acta 24 (1979) 451.

Rama Krishna L, Rybalko A V, and Sundararajan G, Process for forming coatings on metallic bodies and an apparatus for carrying out the process, (2005) US 6,893,551 B2.

Snizhko L O, Yerokhin A L, Pilkington A, Gurevina N L, Misnyankin D O, Leyland A, and Matthews A, Electrochim Acta 49 (2004) 2085.

Saikiran A, Hariprasad S, Arun S, Rama Krishna L, and Rameshbabu N, Surf Coat Technol 372 (2019) 239.

Wheeler J M, Curran J A, and Shrestha S, Surf Coat Technol 207 (2012) 480.

Ramakrishnan E, Premchand C, Manojkumar P, and Rameshbabu N, Mater. Today (2021, in press).

Acknowledgements

The author (NRB) would also like to thank and acknowledge the financial support received from the Defence Research and Development Organisation (DRDO), New Delhi (No. EMR/2016/003259 dated 22-03-2017) to carry out this research

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Premchand, C., Hariprasad, S., Saikiran, A. et al. Assessment of Corrosion and Scratch Resistance of Plasma Electrolytic Oxidation and Hard Anodized Coatings Fabricated on AA7075-T6. Trans Indian Inst Met 74, 1991–2002 (2021). https://doi.org/10.1007/s12666-021-02289-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02289-4