Abstract

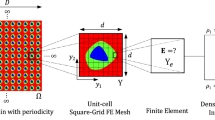

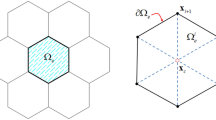

Strength-oriented optimization of porous periodic microstructures impacts on efficient design of load-bearing lightweight structures avoiding mechanical failure. In this work, the maximal von-Mises stress, predicted by homogenization theory on a planar representative unit-cell domain, is minimized using either shape or topology design changes. Plane stress and linear behaviour are assumed. Two benchmarks problems are revisited, bulk and shear loads. Firstly, a fully stressed design is sought on extremal materials, rank-2 laminates, for comparative purposes. The lamination factors are handled analytically to find a relationship between stress and material volume fraction. Secondly, one numerically minimizes the peak von-Mises stress of single-material unit-cell varying shape or topology. In shear, the optimal topology design tends to approximate its rank-2 counterpart. Under bulk load, the peak stresses are further decreased by allowing an inhomogeneous solid phase. An extra material discrete phase is included in the shape problem while functionally graded material solutions are allowed in the topology problem. The single-material optimal results are consistent with the theoretical ones. This validates not only the proposed shape parameterization problem, based on supershapes, but also the proposed stress-based formulation for microstructural topology optimization, not yet extensively addressed in the literature. The multi-material approaches, to the extent of ideally allowing each spatial point to have a different material property, show that by increasing the material design freedom one achieves lower peak stresses.

Similar content being viewed by others

References

Allaire G, Aubry S (1999) On optimal microstructures for a plane shape optimization problem. Struct Optim 17:89–94

Allaire G, Kohn RV (1995) Optimal bounds on the effective behavior of a mixture of two well-ordered elastic materials. Quart Appl Appl Math 51:643–674

Banichuk NV (1977) Optimality conditions in the problem of seeking the hole shapes in elastic bodies. J Appl Math Mech 41(5):946–951

Banichuk NV (1983) Problems and methods of optimal structural design. Plenum Press, New York

Bendsøe M, Sigmund O (1999) Material interpolation schemes in topology optimization. Arch Appl Mech 69:635–654

Bendsøe M, Sigmund O (2003) Topology optimization. theory, methods, and applications. Springer, Berlin Heidelberg New York

Bruggi M (2008) On an alternative approach to stress constraints relation in topology optimization. Struct Multidiscip Optim 36:125–141

Bruns TE, Tortorelli DA (2001) Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng 190:3443–3459

Cadman JE, Zhou S, Chen Y, Li Q (2013) On design of multi-functional microstructural materials. J Mater Sci 48:51–66

Cherepanov GP (1974) Inverse problems of the plane theory of elasticity. J Appl Math Mech 38:915–931

Cherkaev AV, Gibiansky LV (1993) Coupled estimates for the bulk and shear moduli of a two-dimensional isotropic elastic composite. J Mech Phys Solids 41:937–980

Cherkaev AV, Grabovsky Y, Movchan AB, Serkov SK (1998) The cavity of the optimal shape under the shear stresses. Int J Solids Struct 35:4391–4410

Coelho PG, Reis RAR, Guedes JM (2016a) Convergence analysis of stress fields to homogenization predictions in optimal periodic composite design. In: Papadrakakis M, Papadopoulos V, Stefanou G, Plevris V (eds) Proceedings of VII European Congress on Computational Methods in Applied Sciences and Engineering, Crete Island, 5–10 June 2016, https://doi.org/10.7712/100016.1956.6757

Coelho PG, Amiano LD, Guedes JM, Rodrigues HC (2016b) Scale-size effects analysis of optimal periodic material microstructures designed by the inverse homogenization method. Comput Struct 174:21–32

Coelho PG, Guedes JM, Cardoso JB (2019) Topology optimization of cellular materials with periodic microstructure under stress constraints. Struct Multidiscip Optim 59:633–645

Collet M, Noël L, Bruggi M, Duysinx P (2018) Topology optimization for microstructural design under stress constraints. Struct Multidiscip Optim 58:2677–2695

Conlan-Smith C, James KA (2019) A stress-based topology optimization method for heterogeneous structures. Struct Multidiscip Optim 60:167–183

Duysinx P, Bendsøe MP (1998) Topology optimization of continuum structures with local stress constraints. Int J Numer Methods Eng 43:1453–1478

Francfort GA, Murat F (1986) Homogenization and optimal bounds in linear elasticity. Arch Ration Mech Anal 94:307–334

Gielis J (2003) A generic geometric transformation that unifies a wide range of natural and abstract shapes. Amer J Botany 90(3):333–338

Gielis J (2017) The geometrical beauty of plants. Atlantic Press, Paris. https://doi.org/10.2991/978-94-6239-151-2

Goyat V, Verma S, Garg RK (2019) Stress concentration reduction using different functionally graded materials layer around their hole in an infinite panel. Strength Fracture Complexity 1:1–15

Grabovsky Y, Kohn R (1995a) Microstructures minimizing the energy of a two phase elastic composite in two space dimensions I: the confocal ellipse construction. J Mech Physical Solids 43(6):933–947

Grabovsky Y, Kohn RV (1995b) Microstructures minimizing the energy of a two phase elastic composite in two space dimensions. II: The vigdergauz microstructure J Mech Phys Solids 43:949–972

Guedes JM, Kikuchi N (1990) Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput Methods Appl Mech Eng 83:143–198

Guedes JM, Rodrigues HC, Bendsøe M (2003) A material optimization model to approximate energy bounds for cellular materials under multiload conditions. Struct Multidiscip Optim 25:446–452

Hashin Z (1963) The elastic modlui of heterogeneous materials. J Appl Mech 29:143–150

Hashin Z, Shtrikman S (1963) A variational approach to the theory of the elastic behaviour of multiphase materials. J Mech Phys Solids 11:127–140

Haug EJ, Choi KK, Komkov V (1986) Design sensitivity analysis of structural systems. Academis Press Inc., Orlando

Ituarte IF, Boddeti N, Hassani V, Dunn ML, Rosen DW (2019) Design and additive manufacture of functionally graded structures based on digital materials. Addit Manuf 30:100839

Kang Z, Wu C, Luo Y, Li M (2019) Robust topology optimization of multi-material structures considering uncertain graded interface. Compos Struct 208:395–406

Kim J-H, Paulino GH (2002) Isoparametric graded finite elements for non-homogeneous isotropic and orthotropic materials. J Appl Mech 69(4):502–514

Kumar AV (2019) Conceptual design of structures using an upper bound of von Mises stress. J Comput Inf Sci Eng 19:011005–011001

Lian H, Christiansen AN, Tortorelli DA, Sigmund O (2017) Combined shape and topology optimization for minimization of maximal von Mises stress. Struct Multidiscip Optim 55:1541–1557

Lipton R (2002) Design of functionally graded composite structures in the presence of stress constraints. Int J Solids Struct 39:2575–2586

Milton GW, Cherkaev AV (1995) Which elasticity tensors are realizable? J Eng Mater Technol 117:483–493

Nie GJ, Zhong Z, Batra RC (2018) Material tailoring for reducing stress concentration factor at a circular hole in a functionally graded material (FGM) panel. Compos Struct 205:49–57

Noël L, Duysinx P (2017) Shape optimization of microstructural designs subject to local stress constraints within an XFEM-level set framework. Struct Multidiscip Optim 55:2323–2338

Norato J (2018) Topology optimization with supershapes. Struct Multidic Optim 58:415–434

Paulino GH, Silva ECN, Le CH (2009) Optimal design of periodic functionally graded composites with prescribed properties. Struct Multidiscip Optim 38:469–489

Pedersen P (1988) Design for minimum stress concentration — some practical aspects. In: Rozvany GIN, Karihaloo BL (eds) Structural Optimization. Springer, Dordrecht. https://doi.org/10.1007/978-94-009-1413-1_29

Pedersen P (2000) On optimal shapes in materials and structures. Struct Multidiscip Optim 19:169–182

Prager W (1968) Optimality criteria in structural design. Proc Natl Acad Sci 61(3):794–796

Sburlati R (2013) International Journal of Solids and Structures Stress concentration factor due to a functionally graded ring around a hole in an isotropic plate. Int J Solids Struct 50:3649–3658

Sburlati R, Atashipour SR, Atashipour SA (2014) Reduction of the stress concentration in a homogeneous panel with hole by using a functionally graded layer. Compos Part B 61:99–1090

Sigmund O (1994) Materials with prescribed constitutive parameters: an inverse homogenization problem. Int J Solids Struct 31(17):2313–2329

Sigmund O (2000) A new class of extremal composites. J Mech Phys Solids 48:397–428

Sigmund O (2007) Morphology-based black and white filters for topology optimization. Struct Multidiscip Optim 33:401–424

Sigmund O, Maute K (2013) Topology optimization approaches – a comparative review. Struct Multidiscip Optim 48:1031–1055

Stump FV, Silva ECN, Paulino GH (2007) Optimization of material distribution in functionally graded structures with stress constraints. Commun Numer Meth Engng 23:535–551

Svanberg K (1987) The method of moving asymptotes—a new method for structural optimization. Int J Numer Methods Eng 24:359–373

Taylor JE, Bendsøe MP (1984) An interpretation of min-max structural design problems including a method for relaxing constraints. Int J Solids Struct 20:301–314

Verbart A, Langelaar M, Verbart A, Langelaar M, Keulen FV (2017) A unified aggregation and relaxation approach for stress-constrained topology optimization. Struct Multidiscip Optim 55:663–679

Vigdergauz S (1976) Integral equation of the inverse problem of the plane theory of elasticity. J Appl Math Mech 40(3):518–522

Vigdergauz S (1993) Optimal stiffening of holes under equibiaxial tension. Int J Solids Struct 30(4):569–577

Vigdergauz S (1994) Two-dimensional grained composites of extreme rigidity. J Appl Mech 61:390–394

Vigdergauz S (1997) Two-dimensional grained composites of minimum stress concentration. Int J Solids Struct 34(6):661–672

Vigdergauz S (2001a) Genetic algorithm perspective to identify energy optimizing inclusions in an elastic plate. Int J Solids Struct 38:6851–6867

Vigdergauz S (2001b) The effective properties of a perforated elastic plate numerical optimization by genetic algorithm. Int J Solids Struct 38:8593–8616

Vigdergauz S (2002) Genetic algorithm optimization of the effective Young moduli in a perforated plate. Struct Multidiscip Optim 24:106–117

Vigdergauz S (2006) The stress-minimizing hole in an elastic plate under remote shear. J Mech Mater Struct 1(2):387–406

Vigdergauz S (2007) Shape optimization of a rigid inclusion in a shear-loaded elastic plate. J Mech Mater Struct 2(2):275–291

Vigdergauz S (2010) Stress smoothing holes in planar elastic domains. J Mech Mater Struct 5(6):987–1006

Vigdergauz S (2016) A planar grained structure with a multiphase nested inclusion in a periodic cell: Elastostatic solution and the equistressness. Math Mech Solids 21(6):709–724

Vigdergauz S, Cherkaev A (1986) A hole in a plate, optimal for its biaxial extension-compression. J Appl Math Mech 50(3):401–404

Xia Q, Wang MY (2008) Simultaneous optimization of the material properties and the topology of functionally graded structures. Comput Aided Des 40:660–675

Yang Q, Gao C-F, Chen W (2010) Stress analysis of a functional graded material plate with a circular hole. Arch Appl Mech 80:895–907

Zhou M, Sigmund O (2017) On fully stressed design and p-norm measures in structural optimization. Struct Multidiscip Optim 56:731–736

Acknowledgements

The authors wish to thank Professor Krister Svanberg (Royal Institute of Technology, Stockholm, Sweden) for the MMA optimization code.

Funding

This study received financial support from Fundação para a Ciência e a Tecnologia (FCT–MCTES) through the projects UIDB/00667/2020 (UNIDEMI) and UIDB/50022/2020 (IDMEC/LAETA) and PhD scholarship SFRH/BD/136744/2018.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Replication of results

Our manuscript details the input and output data by means of figures and tables such that results can be reproduced and confirmed. In addition to that, supershape parameters are provided in Appendix 1 Tables 5, 6, 7, and 8. Equations are presented in such way that readers can implement or solve them. Actually, we also use in this paper implementations that are already available in the literature as the homogenization and MMA codes.

Additional information

Responsible Editor: Gregoire Allaire

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1 Values for the supershape parameters

Appendix 1 Values for the supershape parameters

Tables 5, 6, 7 and 8 present the values found for the supershape parameters in the SO problems solved.

Rights and permissions

About this article

Cite this article

Coelho, P.G., Barroca, B.C., Conde, F.M. et al. Minimization of maximal von Mises stress in porous composite microstructures using shape and topology optimization. Struct Multidisc Optim 64, 1781–1799 (2021). https://doi.org/10.1007/s00158-021-02942-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-021-02942-y