Abstract

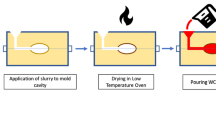

Chemically bonded sand systems are an important part of foundry technology and their interactions at the mold-steel interface are of great interest. With today’s emphasis on near-net-shape steel castings and more stringent dimensional requirements, there is a need to characterize as-cast surface quality. Part I of this two-part paper focused on surface quality at uncoated as-cast steel/chemically bonded sand interfaces. The results of Part I suggest that refractory coating (wash) technologies may be required. Therefore, Part II focuses on studying the effects of refractory coating, metal, and chemically bonded sand system on as-cast surface quality. Refractory coatings, designed for steel castings, were applied to disk-shaped specimens by four industrial partners using normal production techniques. A small and practical casting trial, using disk-shaped specimen cores, was developed at Western Michigan University. This trial allows several core specimens to be wetted simultaneously from a known head pressure, temperature, and steel alloy. The casting trials were conducted at Saginaw Valley State University. The results show that various combinations of refractory coatings and chemically bonded sand systems provide different as-cast surface quality. Also, a new refractory coating technology (sol–gel) may provide a superior as-cast surface quality with silica and ceramic sands in a steel casting. Traditional refractory coatings, while still better than no coating, performed worse. Finally, the refractory coatings can affect the shakeout/collapsibility of a chemically bonded sand system. Overall, this indicates that more engineering of these coatings may be required for steel.

Similar content being viewed by others

References

R. Tuttle, S. Ramrattan, & L. Wells, As-cast surface characterization for steel using disk-shaped chemically bonded sand specimens. Inter. Metalcast. 15, 382–390 (2021). https://doi.org/10.1007/s40962-020-00520-4

S.N. Ramrattan, S.F. Cheah, O.B. Guyer, K.M. Fisher, Comparing refractory coatings on shell sand utilizing elevated temperature and collapsibility testing. AFS Trans. 112, 689–696 (2004)

S.N. Ramrattan, M.K. Joyce, Wet to dry—refractory coating control for precision PUCB sands. Inter. Metalcast. 5(2), 7–22 (2011). https://doi.org/10.1007/BF03355468

AFS 4-F Mold-Metal Interface Reactions Committee, Baumè: Complete Coating Control? Phase I: variability of coating control test. AFS Trans. 112, 683–688 (2004)

O.B. Guyer, R.C. Emptage, S.N. Ramrattan, The effect of refractory coating thermal heat transfer on phenolic urethane cold box core distortion at iron temperature and pressure. AFS Trans. 113, 485–494 (2005)

S. Ramrattan, L. Wells, P. Patel, J. Shoemaker, Qualification of chemically bonded sand systems using a casting trial for quantifying interfacial defects. Inter. Metalcast. 12(2), 214–223 (2018). https://doi.org/10.1007/s40962-017-0166-3

U.C. Nwaogu, N.S. Tiedje, New sol–gel coatings to improve casting quality. DTU Mechanical Engineering (2011)

A.C. Pierre, Introduction to Sol–Gel Processing (Springer Science + Business Media, Berlin, 1998)

Ž. Maša, P. Mitja, V. Maja, Č. Janko, M. Jože, C.K. Romana, Application of sol–gel technology in foundry coatings. in, V: Križman, Alojz (ur.). Zbornik referatov = Conference proceedings (Društvo livarjev Slovenije, Ljubljana, 2018), Str. 1–9

Acknowledgments

The authors thank the metal casting students at SVSU (H. Towalski, K. Konwinski, and I. Portice) and WMU (A. Patel, M. Patel, K. Pathak, and K. Shenoy) for their support with casting trials and laboratory testing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tuttle, R., Ramrattan, S., Wells, L. et al. Refractory Coated Surface Characterization for Steel using Disk-Shaped Chemically Bonded Sand Specimens—Part II. Inter Metalcast 16, 493–501 (2022). https://doi.org/10.1007/s40962-021-00618-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00618-3