Abstract

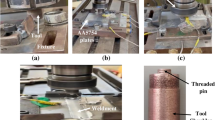

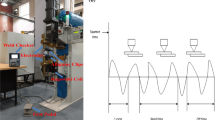

Tailor welded blank sheets made of friction stir welding (FSW) process have found many applications in aerospace, automobile, marine, and other industries. In the present study, two different aluminum alloys AA5083-O and AA6082-T6 having 2 mm thickness were used. This research presents the multi-responses optimization of process parameters, i.e., rotation speed (R), travel speed (T), and shoulder diameter (S) in the FSW process using response surface methodology (RSM) based on gray relational analysis (GRA) coupled with principal component analysis (PCA) technique. For the optimization of the process, the face-centered central composite design technique with minimal design was used to get the optimum level of the parameter. The objective of this paper is to find out the optimum level of the process parameters which yields the maximum responses, i.e., ultimate tensile strength, total elongation, yield strength, dome height, and microhardness value. ANOVA technique was used to ensure the significant contribution of the individual and the combination of process parameters. The confirmatory run analyzed the optimized process parameters, and the experimental result was observed within 2.6% of error agreement with predicted values. GRA determined the optimum value of the input parameter with the PCA technique, a hybrid approach. The optimum value of R, T, and S was found at 1900 rpm, 40 mm/min, 12 mm, respectively. The microstructural study of variation in grain structure across the different zones of the FSW region was examined and tested by scanning electron microscope. The microhardness and formability tests for the optimized parameters were carried out. This research reveals that the multi-response optimization problem can be easily solved through RSM based GRA-PCA approach.

Similar content being viewed by others

References

Mishra RS, Ma ZY. Friction stir welding and processing. 2005; 50:1–78.

Ahn BW, Choi DH, Kim DJ, Jung SB. Microstructures and properties of friction stir welded 409L stainless steel using Si3N4 tool. Mater Sci Eng. A. 2012; 532:476–9. https://doi.org/10.1016/j.msea.2011.10.109

Lee WB, Lee CY, Chang WS, Yeon YM, Jung SB. Microstructural investigation of friction stir welded pure titanium. Mater Lett. 2005;59(26):3315–8.

Reynolds AP, Tang W, Gnaupel-Herold T, Prask H. Structure, properties, and residual stress of 304L stainless steel friction stir welds. Scr Mater. 2003;48(9):1289–94.

Ghaffarpour M, Dariani BM, Hossein Kokabi A, Razani NA. Friction stir welding parameters optimization of heterogeneous tailored welded blank sheets of aluminium alloys 6061 and 5083 using response surface methodology. Proc Inst Mech Eng Part B J Eng Manuf. 2012;226(12):2013–22.

Kasman Ş. Multi-response optimization using the Taguchi-based grey relational analysis: A case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111. Int J Adv Manuf Technol. 2013;68(1–4):795–804.

Babajanzade Roshan S, Behboodi Jooibari M, Teimouri R, Asgharzadeh-Ahmadi G, Falahati-Naghibi M, Sohrabpoor H. Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol. 2013;69(5–8):1803–18.

Singh G, Singh K, Singh J. Modelling of the effect of process parameters on tensile strength of friction stir welded aluminium alloy joints. Exp Tech. 2014;38(3):63–71.

Kumar S, Kumar S, Kumar A. Optimization of process parameters for friction stir welding of joining A6061 and A6082 alloys by Taguchi method. Proc Inst Mech Eng Part C J Mech Eng Sci. 2013;227(6):1150–63.

Trimble D, O’Donnell GE, Monaghan J. Characterisation of tool shape and rotational speed for increased speed during friction stir welding of AA2024-T3. J Manuf Process [Internet]. 2015;17:141–50. https://doi.org/10.1016/j.jmapro.2014.08.007

Arora A, De A, Debroy T. Toward optimum friction stir welding tool shoulder diameter. Scr Mater. 2011;64(1):9–12.

Giraud L, Robe H, Claudin C, Desrayaud C, Bocher P, Feulvarch E. Investigation into the dissimilar friction stir welding of AA7020-T651 and AA6060-T6. J Mater Process Technol [Internet]. 2016;235:220–30. https://doi.org/10.1016/j.jmatprotec.2016.04.020

Hirata T, Oguri T, Hagino H, Tanaka T, Chung SW, Takigawa Y, et al. Influence of friction stir welding parameters on grain size and formability in 5083 aluminum alloy. Mater Sci Eng A. 2007;456(1–2):344–9.

Yuan SJ, Hu ZL, Wang XS, Liu G, Liu HJ. Effect of post-weld annealing treatment on plastic deformation of 2024 friction-stir-welded joints. J Mater Eng Perform. 2012;21(6):920–6.

Sharma N, Siddiquee AN, Khan ZA, Mohammed MT. Material stirring during FSW of Al–Cu: Effect of pin profile. Mater Manuf Process. 2018;33(7):786–94.

Babu NBK, Davidson MJ, Neelakanteswara Rao A. Investigation on the Influence of the Lubrication on the Formability of Dissimilar Tailor Welded Blanks. Trans Indian Inst Met. 2015;68(4):529–34.

Kalemba-Rec I, Kopyściański M, Miara D, Krasnowski K. Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys. Int J Adv Manuf Technol. 2018;97(5–8):2767–79.

Ahmadnia M, Shahraki S, Kamarposhti MA. Experimental studies on optimized mechanical properties while dissimilar joining AA6061 and AA5010 in a friction stir welding process. Int J Adv Manuf Technol. 2016;87(5–8):2337–52.

Sertan K. Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state RS. 2017;30(2009):2211–21.

Gautam V, Raut VM, Kumar DR. Analytical prediction of spring back in bending of tailor-welded blanks incorporating the effect of anisotropy and weld zone properties. Proc Inst Mech Eng Part L J Mater Des Appl. 2018;232(4):294–306.

21. Lee W, Chung K, Kim D, Kim J, Kim C, Okamoto K, et al. Experimental and numerical study on formability of friction stir welded TWB sheets based on hemispherical dome stretch tests. Int J Plast [Internet]. 2009;25(9):1626–54. https://doi.org/10.1016/j.ijplas.2008.08.005

Kumar S, Kumar DR, Kumar H, Nath AK. Characterization of tensile properties of tailor welded IF steel sheets and their formability in stretch forming. 2007;183:321–32.

Ghangas G, Singhal S. Modelling and optimization of process parameters for friction stir welding of armor alloy using RSM and GRA-PCA approach. Mater Res Express. 2019;6(2).

Kundu J, Singh H. Friction stir welding: multi-response optimisation using Taguchi-based GRA. Prod Manuf Res [Internet]. 2016;4(1):228–41. https://doi.org/10.1080/21693277.2016.1266449

Wakchaure KN, Thakur AG, Gadakh V, Kumar A. Multi-Objective Optimization of Friction Stir Welding of Aluminium Alloy 6082-T6 Using hybrid Taguchi-Grey Relation Analysis- ANN Method. Mater Today Proc [Internet]. 2018;5(2):7150–9. https://doi.org/10.1016/j.matpr.2017.11.380

Vijayan S, Raju R, Rao SRK. Multiobjective optimization of friction stir welding process parameters on aluminum aalloy AA 5083 using Taguchi-based grey relation analysis. Mater Manuf Process. 2010;25(11):1206–12.

Vijayan D, Rao VS. Friction Stir Welding of Age-Hardenable Aluminum Alloys: A Parametric Approach Using RSM Based GRA Coupled With PCA. J Inst Eng Ser C. 2014;95(2):127–41.

Scialpi A, De Filippis LAC, Cavaliere P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater Des. 2007;28(4):1124–9.

Sakthivel T, Sengar GS, Mukhopadhyay J. Effect of welding speed on microstructure and mechanical properties of friction-stir-welded aluminum. Int J Adv Manuf Technol. 2009;43(5–6):468–73.

Gungor B, Kaluc E, Taban E, Sik A. Mechanical, fatigue and microstructural properties of friction stir welded 5083-H111 and 6082-T651 aluminum alloys. Mater Des [Internet]. 2014;56:84–90. https://doi.org/10.1016/j.matdes.2013.10.090

Jamshidi Aval H, Serajzadeh S, Kokabi AH. The influence of tool geometry on the thermo-mechanical and microstructural behavior in friction stir welding of AA5086. Proc Inst Mech Eng Part C J Mech Eng Sci. 2011;225(1):1–16.

Simar A, Bréchet Y, De Meester B, Denquin A, Gallais C, Pardoen T. Integrated modeling of friction stir welding of 6xxx series Al alloys: Process, microstructure, and properties. Prog Mater Sci [Internet]. 2012;57(1):95–183. https://doi.org/10.1016/j.pmatsci.2011.05.003

Ouyang JH, Kovacevic R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys. J Mater Eng Perform. 2002;11(1):51–63.

Kalemba-Rec I, Hamilton C, Kopyściański M, Miara D, Krasnowski K. Microstructure and Mechanical Properties of Friction Stir Welded 5083 and 7075 Aluminum Alloys. J Mater Eng Perform. 2017;26(3):1032–43.

Singh K, Singh G, Singh H. Investigation on the microstructure and mechanical properties of a dissimilar friction stir welded joint of magnesium alloys. Proc Inst Mech Eng Part L J Mater Des Appl. 2019;233(12):2444–54.

Acknowledgements

The authors genuinely express their gratefulness to (Prof.) Dr. Vijay Gautam, Delhi Technological University, Delhi, for extending his valuable suggestion and providing the facilities of the metal forming laboratory to carry out the tensile and limiting dome height test. The authors also would like to thank CAPIER, DTU for providing the facility for microhardness test.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) affirms that there is no conflict of interest with respect to the present study, authorship, and publication of this research paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, P., Sharma, S. Influence of FSW Process Parameters on Formability and Mechanical Properties of Tailor Welded Blanks AA6082-T6 and AA5083-O Using RSM with GRA-PCA Approach. Trans Indian Inst Met 74, 1943–1968 (2021). https://doi.org/10.1007/s12666-021-02255-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02255-0