Abstract

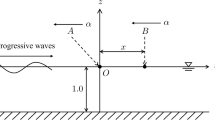

When ultrasonic time-of-flight diffraction (TOFD) B-scan is implemented along the circumferential direction of pipeline, the ray path of direct longitudinal wave (DLW) is not parallel to the curved pipeline surface, inducing the layered dead zone. In this paper, the spectrum analysis method based on Fourier transform is employed to establish the relationship between flaw depth and harmonic frequency interval. On this basis, the relative position between flaw tip and DLW is determined combining with the characteristics of the tip-diffracted waves in B-scan image, realizing the quantitative detection of the defects with different depths. Simulated and experimental results show that the range of dead zone in pipeline is reduced by 40% with spectrum analysis method, and the relative quantitative errors of flaw depths are within 11%. Finally, the formation mechanism of extreme values for the tip-diffracted waves in B-scan image is discussed by theoretical analysis.

Similar content being viewed by others

References

Prager, J., Kitze, J., Acheroy, C., Brackrock, D., Brekow, G., Kreutzbruck, M.: SAFT and TOFD-a comparative study of two defect sizing techniques on a reactor pressure vessel mock-up. J. Nondestruct. Eval. 32(1), 1–13 (2013)

Nath, S.K., Balasubramaniam, K., Krishnamurthy, C.V., Narayana, B.H.: Sizing of surface-breaking cracks in complex geometry components by ultrasonic time-of-flight diffraction (TOFD) technique. Insight Non-Destr. Test. Cond. Monit. 49(4), 200–206 (2007)

Merazi-Meksen, T., Boudraa, M., Boudraa, B.: Mathematical morphology for TOFD image analysis and automatic crack detection. Ultrasonics 54(6), 1642–1648 (2014)

Duan, J.X., Luo, L., Gao, X.R., Peng, J.P., Li, J.L.: Multiframe ultrasonic TOFD weld inspection imaging based on wavelet transform and image registration. J. Sens. 2018, 1–8 (2018)

Baskaran, G., Balasubramaniam, K., Krishnamurthy, C.V., Rao, C.L.: TOFD imaging: ultrasonic TOFD flaw sizing and imaging in thin plates using embedded signal identification technique (ESIT). Insight Non-Destr. Test. Cond. Monit. 46(9), 537–542 (2004)

Baby, S., Balasubramanian, T., Pardikar, R.J., Palaniappan, M., Subbaratnam, R.: Time-of-flight diffraction (TOFD) technique for accurate sizing of surface-breaking cracks. Insight Non-Destr. Test. Cond. Monit. 45(6), 426–430 (2003)

Han, Q.B., Wang, P., Zheng, H.: Modified ultrasonic time-of-flight diffraction testing with barker code excitation for sizing inclined crack. Appl. Acoust. 140, 153–159 (2018)

Yeh, F.W.T., Lukomski, T., Haag, J., Clarke, T., Stepinski, T., Strohaecker, T.R.: An alternative ultrasonic time of flight diffraction (TOFD) method. NDT&E Int. 100, 74–83 (2018)

Taghipour, M.H.: Study and evaluation of advanced TOFD method for inspection of polyethylene pipes but welding. J. Phys. Sci. Appl. 5(5), 349–355 (2015)

Ido, N., Hatanaka, H., Arakawa, T., Katou, K., Furuta, H.: Examination of flaw detection near the surface by the ultrasonic TOFD method. Key Eng. Mater. 270–273, 378–383 (2004)

Chi, D.Z., Gang, T.: Shallow buried defect testing method based on ultrasonic TOFD. J. Nondestruct. Eval. 32(2), 164–171 (2013)

Jin, S.J., Sun, X., Ma, T.T., Ding, N., Lei, M.K., Lin, L.: Quantitative detection of shallow subsurface defects by using mode-converted waves in time-of-flight diffraction technique. J. Nondestruct. Eval. 39(2), 33 (2020)

Baskaran, G., Balasubramaniam, K., Rao, C.L.: Shear-wave time of flight diffraction (S-TOFD) technique. NDT&E Int. 39(6), 458–467 (2006)

Cong, S., Gang, T., Zhang, J.Y., Sheng, C.Y.: Parameter design of linear frequency modulated excitation waveform for ultrasonic nondestructive testing of metallic materials. J. Nondestruct. Eval. 33(4), 684–693 (2014)

Chen, T.L., Que, P.W., Zhang, Q., Liu, Q.K.: Ultrasonic signal identification by empirical mode decomposition and Hilbert transform. Rev. Sci. Instrum. 76(8), 85109 (2005)

Chen, J., Wu, E., Wu, H.T., Zhou, H.M., Yang, K.J.: Enhancing ultrasonic time-of-flight diffraction measurement through an adaptive deconvolution method. Ultrasonics 96, 175–180 (2019)

Li, X., Li, X.B., Liang, W., Chen, L.: l0-norm regularized minimum entropy deconvolution for ultrasonic NDT & E. NDT&E Int. 47, 80–87 (2012)

Zhao, Y., Lin, L., Li, X.M., Lei, M.K.: Simultaneous determination of the coating thickness and its longitudinal velocity by ultrasonic nondestructive method. NDT&E Int. 43(7), 579–585 (2010)

Ma, Z.Y., Zhao, Y., Luo, Z.B., Lin, L.: Ultrasonic characterization of thermally grown oxide in thermal barrier coating by reflection coefficient amplitude spectrum. Ultrasonics 54(4), 1005–1009 (2014)

Haines H., Hörchens L., Tomar P.: Identifying and sizing axial seam weld flaws in ERW pipe seams and SCC in the pipe body using ultrasonic imaging. In: 2016 11th International Pipeline Conference, Calgary, Alberta (2016)

Jin, S.J., Sun, X., Luo, Z.B., Ma, T.T., Lin, L.: Quantitative detection of shallow subsurface cracks in pipeline with time-of-flight diffraction technique. NDT&E Int. 118, 102397 (2021)

Yacef, N., Bouden, T., Grimes, M.: Accurate ultrasonic measurement technique for crack sizing using envelope detection and differential evolution. NDT&E Int. 102, 161–168 (2019)

Manjula, K., Vijayarekha, K., Venkatraman, B.: Quality enhancement of ultrasonic TOFD signals from carbon steel weld pad with notches. Ultrasonics 84, 264–271 (2018)

Habibpour-Ledari, A., Honarvar, F.: Three dimensional characterization of defects by ultrasonic time-of-flight diffraction (TOFD) technique. J. Nondestruct. Eval. 37(1), 14 (2018)

Fitting, D.W., Adler, L.: Ultrasonic Spectral Analysis for Nondestructive Evaluation. Plenum Press, New York (1981)

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Grant No. 2019YFA0709003), the National Natural Science Foundation of China (Grant No. 51905079), the Dalian Science and Technology Innovation Fund (Grant No. 2020JJ26GX041) and the Fundamental Research Funds for the Central Universities (Grant No. DUT20ZD204).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jin, S.J., Zhang, B., Sun, X. et al. Reduction of Layered Dead Zone in Time-of-Flight Diffraction (TOFD) for Pipeline with Spectrum Analysis Method. J Nondestruct Eval 40, 48 (2021). https://doi.org/10.1007/s10921-021-00781-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-021-00781-x