Abstract

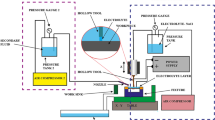

Due to rising attention towards environmental and ecological issues caused by mineral oil-based lubricants in machining operations, the developing of an environmental favourable lubricant has become inevitable. As environmental favourable cutting fluids, vegetable oils have acquired great attention in machining operations due to their good biodegradability, non-toxicity and less environmental pollutant properties. Nowadays, the minimum quantity lubrication (MQL) technique is explored as alternative technique to conventional flood cooling technique. However, very limited work is done to investigate the effect of MQL technique using vegetable oils as the base oil for machining of hard materials. Moreover, systematic comparison of different vegetable oils as the base oil will be of great significance to the manufacturing industry. Therefore, in this study, the performance of six vegetable oils viz. castor, coconut, soybean, canola, palm and sunflower oil, and distilled water has been investigated during drilling of stainless steel (AISI 321) using minimum quantity lubrication technology. The main objective of this study is to compare the performance of various cooling strategies viz. dry, flood and seven MQL conditions with respect to drilling characteristics (thrust force, torque, surface roughness, coefficient of friction (COF), chip morphology and wear mechanism) in the drilling of stainless steel (AISI 321) by using HSS drill tools. Experimental findings showed that MQL drilling conditions have given excellent drilling performance by improving drilling characteristics than dry and flood drilling. Among the MQL fluids, sunflower oil provided better lubrication and improved the drilling characteristics followed by palm, canola, soybean, coconut, castor oil and distilled water. Sunflower oil had a thrust force, torque, surface roughness and coefficient of friction of 1425 N, 22.8 Nm, 4.356 µm and 4.000 µ, which reduced by 21.27%, 25.49%, 30.72% and 5.35%, respectively than that under flood drilling at 30th hole. The better lubrication performance of sunflower oil may be attributed to the rich presence of saturated-fatty acids. In addition, vegetable oils based MQL technique is more worthy to improve the cooling capabilities and promote sustainability in the manufacturing sector by saving resources and extending environmental benefits.

Similar content being viewed by others

References

Cetin, M. H., Ozcelik, B., Kuram, E., & Demirbas, E. (2011). Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method. Journal of Cleaner Production, 19(17–18), 2049–2056. https://doi.org/10.1016/j.jclepro.2011.07.013

Ozcelik, B., Kuram, E., Huseyin Cetin, M., & Demirbas, E. (2011). Experimental investigations of vegetable based cutting fluids with extreme pressure during turning of AISI 304L. Tribology International, 44(12), 1864–1871. https://doi.org/10.1016/j.triboint.2011.07.012

Ghani, J. A., Rizal, M., & Che Haron, C. H. (2014). Performance of green machining: A comparative study of turning ductile cast iron FCD700. Journal of Cleaner Production, 85, 289–292. https://doi.org/10.1016/j.jclepro.2014.02.029

Rahim, E. A., Ibrahim, M. R., Rahim, A. A., Aziz, S., & Mohid, Z. (2015). Experimental investigation of minimum quantity lubrication (MQL) as a sustainable cooling technique. Procedia CIRP, 26, 351–354. https://doi.org/10.1016/j.procir.2014.07.029

Ribeiro Filho, S. L. M., Vieira, J. T., de Oliveira, J. A., Arruda, É. M., & Brandão, L. C. (2017). Comparison among different vegetable fluids used in minimum quantity lubrication systems in the tapping process of cast aluminum alloy. Journal of Cleaner Production, 140, 1255–1262. https://doi.org/10.1016/j.jclepro.2016.10.032

Lawal, S. A., Choudhury, I. A., & Nukman, Y. (2013). A critical assessment of lubrication techniques in machining processes: A case for minimum quantity lubrication using vegetable oil-based lubricant. Journal of Cleaner Production, 41, 210–221. https://doi.org/10.1016/j.jclepro.2012.10.016

Tawakoli, T., Hadad, M. J., & Sadeghi, M. H. (2010). Influence of oil mist parameters on minimum quantity lubrication—MQL grinding process. International Journal of Machine Tools and Manufacture, 50(6), 521–531. https://doi.org/10.1016/j.ijmachtools.2010.03.005

Pal, A., Chatha, S. S., & Singh, K. (2020). Performance evaluation of minimum quantity lubrication technique in grinding of AISI 202 stainless steel using nano-MoS2 with vegetable-based cutting fluid. The International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-020-05840-7

Pal, A., Chatha, S. S., & Sidhu, H. S. (2021). Tribological characteristics and drilling performance of nano-MoS2-enhanced vegetable oil-based cutting fluid using eco-friendly MQL technique in drilling of AISI 321 stainless steel. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 43(4), 1–20

Sayuti, M., Sarhan, A. A. D., & Salem, F. (2014). Novel uses of SiO2 nano-lubrication system in hard turning process of hardened steel AISI4140 for less tool wear, surface roughness and oil consumption. Journal of Cleaner Production, 67, 265–276. https://doi.org/10.1016/j.jclepro.2013.12.052

Bhowmick, S., Lukitsch, M. J., & Alpas, A. T. (2010). Dry and minimum quantity lubrication drilling of cast magnesium alloy (AM60). International Journal of Machine Tools and Manufacture, 50(5), 444–457. https://doi.org/10.1016/j.ijmachtools.2010.02.001

Meena, A., & El Mansori, M. (2011). Study of dry and minimum quantity lubrication drilling of novel austempered ductile iron (ADI) for automotive applications. Wear, 271(9–10), 2412–2416. https://doi.org/10.1016/j.wear.2010.12.022

Niketh, S., & Samuel, G. (2018). Drilling performance of micro textured tools under dry, wet and MQL condition. Journal of Manufacturing Processes, 32, 254–268

Tawakoli, T., Hadad, M. J., Sadeghi, M. H., Daneshi, A., Stöckert, S., & Rasifard, A. (2009). An experimental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication—MQL grinding. International Journal of Machine Tools and Manufacture, 49(12–13), 924–932. https://doi.org/10.1016/j.ijmachtools.2009.06.015

Sadeghi, M., Hadad, M., Tawakoli, T., Vesali, A., & Emami, M. (2010). An investigation on surface grinding of AISI 4140 hardened steel using minimum quantity lubrication-MQL technique. International Journal of Material Forming, 3(4), 241–251

Mao, C., Zou, H., Huang, Y., Li, Y., & Zhou, Z. (2013). Analysis of heat transfer coefficient on workpiece surface during minimum quantity lubricant grinding. The International Journal of Advanced Manufacturing Technology, 66(1–4), 363–370

Li, C. H., Hou, Y. L., Xiu, S. C., & Cai, G. Q. (2008). Application of lubrication theory to near-dry green grinding–feasibility analysis. Advanced materials research, Vol 44. (pp. 135–142). Trans Tech Publ.

Dhar, N. R., Kamruzzaman, M., & Ahmed, M. (2006). Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. Journal of Materials Processing Technology, 172(2), 299–304. https://doi.org/10.1016/j.jmatprotec.2005.09.022

Dhar, N. R., Ahmed, M. T., & Islam, S. (2007). An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. International Journal of Machine Tools and Manufacture, 47(5), 748–753. https://doi.org/10.1016/j.ijmachtools.2006.09.017

Priarone, P. C., Robiglio, M., Settineri, L., & Tebaldo, V. (2014). Milling and turning of titanium aluminides by using minimum quantity lubrication. Procedia CIRP, 24, 62–67. https://doi.org/10.1016/j.procir.2014.07.147

Alves, S. M., & de Oliveira, J. F. G. Vegetable based cutting fluid: An environmental alternative to grinding process. In LCE 2008: 15th CIRP international conference on life cycle engineering: Conference proceedings, 2008 (p. 664). CIRP.

Stachurski, W., Sawicki, J., Krupanek, K., & Nadolny, K. (2020). Application of numerical simulation to determine ability of air used in MQL method to clean grinding wheel active surface during sharpening of hob cutters. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-020-00239-x

Lee, C.-M., Choi, Y.-H., Ha, J.-H., & Woo, W.-S. (2017). Eco-friendly technology for recycling of cutting fluids and metal chips: A review. International Journal of Precision Engineering and Manufacturing-Green Technology, 4(4), 457–468

Zhang, Y., Li, C., Jia, D., Zhang, D., & Zhang, X. (2015). Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. Journal of Cleaner Production, 87, 930–940. https://doi.org/10.1016/j.jclepro.2014.10.027

Yin, Q., Li, C., Dong, L., Bai, X., Zhang, Y., Yang, M., et al. (2021). Effects of physicochemical properties of different base oils on friction coefficient and surface roughness in MQL milling AISI 1045. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-021-00318-7

Lawal, S. A., Choudhury, I. A., & Nukman, Y. (2014). Evaluation of vegetable and mineral oil-in-water emulsion cutting fluids in turning AISI 4340 steel with coated carbide tools. Journal of Cleaner Production, 66, 610–618. https://doi.org/10.1016/j.jclepro.2013.11.066

Rahim, E. A., & Sasahara, H. (2011). An analysis of surface integrity when drilling inconel 718 using palm oil and synthetic ester under MQL condition. Machining Science and Technology, 15(1), 76–90

Emami, M., Sadeghi, M. H., Sarhan, A. A. D., & Hasani, F. (2014). Investigating the minimum quantity lubrication in grinding of Al2O3 engineering ceramic. Journal of Cleaner Production, 66, 632–643. https://doi.org/10.1016/j.jclepro.2013.11.018

Wang, Y., Li, C., Zhang, Y., Yang, M., Li, B., Jia, D., et al. (2016). Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. Journal of Cleaner Production, 127, 487–499

Burton, G., Goo, C.-S., Zhang, Y., & Jun, M. B. (2014). Use of vegetable oil in water emulsion achieved through ultrasonic atomization as cutting fluids in micro-milling. Journal of Manufacturing Processes, 16(3), 405–413

Lawal, S., Choudhury, I., & Nukman, Y. (2012). Application of vegetable oil-based metalworking fluids in machining ferrous metals—a review. International Journal of Machine Tools and Manufacture, 52(1), 1–12

Bhowmick, S., & Alpas, A. T. (2008). Minimum quantity lubrication drilling of aluminium–silicon alloys in water using diamond-like carbon coated drills. International Journal of Machine Tools and Manufacture, 48(12–13), 1429–1443. https://doi.org/10.1016/j.ijmachtools.2008.04.010

Bhowmick, S., & Alpas, A. T. (2011). The role of diamond-like carbon coated drills on minimum quantity lubrication drilling of magnesium alloys. Surface and Coatings Technology, 205(23–24), 5302–5311. https://doi.org/10.1016/j.surfcoat.2011.05.037

Fasina, O., & Colley, Z. (2008). Viscosity and specific heat of vegetable oils as a function of temperature: 35 C to 180 C. International Journal of Food Properties, 11(4), 738–746

Turgut, A., Tavman, I., & Tavman, S. (2009). Measurement of thermal conductivity of edible oils using transient hot wire method. International Journal of Food Properties, 12(4), 741–747

Sen, B., Mia, M., Krolczyk, G. M., Mandal, U. K., & Mondal, S. P. (2021). Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology, 8(1), 249–280. https://doi.org/10.1007/s40684-019-00158-6

Kuram, E., Ozcelik, B., & Demirbas, E. (2013). Environmentally friendly machining: Vegetable based cutting fluids. Green manufacturing processes and systems. (pp. 23–47). Springer.

Ulrich, K. (2002). Vegetable oil-based coolants improve cutting performance. Journal of Cutting Fluids. http://www.blaser.com/download/Dec02.pdf.

Davis, B., Schueller, J. K., & Huang, Y. (2015). Study of ionic liquid as effective additive for minimum quantity lubrication during titanium machining. Manufacturing Letters, 5, 1–6. https://doi.org/10.1016/j.mfglet.2015.04.001

Geng, D., Lu, Z., Yao, G., Liu, J., Li, Z., & Zhang, D. (2017). Cutting temperature and resulting influence on machining performance in rotary ultrasonic elliptical machining of thick CFRP. International Journal of Machine Tools and Manufacture, 123, 160–170

Nam, J., & Lee, S. W. (2018). Machinability of titanium alloy (Ti-6Al-4V) in environmentally-friendly micro-drilling process with nanofluid minimum quantity lubrication using nanodiamond particles. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(1), 29–35. https://doi.org/10.1007/s40684-018-0003-z

Tazehkandi, A. H., Pilehvarian, F., & Davoodi, B. (2014). Experimental investigation on removing cutting fluid from turning of Inconel 725 with coated carbide tools. Journal of Cleaner Production, 80, 271–281

Belluco, W., & De Chiffre, L. (2004). Performance evaluation of vegetable-based oils in drilling austenitic stainless steel. Journal of Materials Processing Technology, 148(2), 171–176. https://doi.org/10.1016/s0924-0136(03)00679-4

Kuram, E., Ozcelik, B., Demirbas, E., Şik, E., & Tansel, I. N. (2011). Evaluation of new vegetable-based cutting fluids on thrust force and surface roughness in drilling of AISI 304 using Taguchi method. Materials and Manufacturing Processes, 26(9), 1136–1146

Lorain, R., Olivier, L., Poggi, A., Valiorgue, F., & Rech, J. (2019). Identification of friction coefficients when drilling titanium TiAl6V4. Procedia CIRP, 82, 119–123. https://doi.org/10.1016/j.procir.2019.04.004

Rech, J., Arrazola, P., Claudin, C., Courbon, C., Pusavec, F., & Kopac, J. (2013). Characterisation of friction and heat partition coefficients at the tool-work material interface in cutting. CIRP Annals, 62(1), 79–82

Percin, M., Aslantas, K., Ucun, I., Kaynak, Y., & Çicek, A. (2016). Micro-drilling of Ti–6Al–4V alloy: The effects of cooling/lubricating. Precision Engineering, 45, 450–462

Chatha, S. S., Pal, A., & Singh, T. (2016). Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. Journal of Cleaner Production, 137, 537–545

Zainal Abidin, Z., Tarisai Mativenga, P., & Harrison, G. (2020). Chilled air system and size effect in micro-milling of nickel−titanium shape memory alloys. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(2), 283–297. https://doi.org/10.1007/s40684-019-00040-5

Tunc, L. T., Gu, Y., & Burke, M. G. (2016). Effects of minimal quantity lubrication (MQL) on Surface integrity in robotic milling of austenitic stainless steel. Procedia CIRP, 45, 215–218. https://doi.org/10.1016/j.procir.2016.02.337

Molaie, M. M., Akbari, J., & Movahhedy, M. R. (2016). Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. Journal of Cleaner Production, 129, 212–222. https://doi.org/10.1016/j.jclepro.2016.04.080

Wu, S., Liao, H., Li, S., Bi, J., & Li, Z. (2020). High-speed milling of hardened mold steel P20 with minimum quantity lubrication. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-020-00249-9

Li, M., Yu, T., Zhang, R., Yang, L., Ma, Z., Li, B., et al. (2019). Experimental evaluation of an eco-friendly grinding process combining minimum quantity lubrication and graphene-enhanced plant-oil-based cutting fluid. Journal of Cleaner Production, 20, 118747

Pal, A., Chatha, S. S., & Sidhu, H. S. (2020). Experimental investigation on the performance of MQL drilling of AISI 321 stainless steel using nano-graphene enhanced vegetable-oil-based cutting fluid. Tribology International, 20, 106508

Masoudi, S., Esfahani, M. J., Jafarian, F., & Mirsoleimani, S. A. (2019). Comparison the effect of MQL, wet and dry turning on surface topography, cylindricity tolerance and sustainability. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-019-00042-3

Sen, B., Mia, M., Krolczyk, G., Mandal, U. K., & Mondal, S. P. (2019). Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology, 20, 1–32

Iyappan, S. K., & Ghosh, A. (2020). Small quantity lubrication assisted end milling of aluminium using sunflower oil. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(2), 337–345. https://doi.org/10.1007/s40684-019-00081-w

Jia, D., Li, C., Zhang, Y., Yang, M., Wang, Y., Guo, S., et al. (2017). Specific energy and surface roughness of minimum quantity lubrication grinding Ni-based alloy with mixed vegetable oil-based nanofluids. Precision Engineering, 50, 248–262

Debnath, S., Reddy, M. M., & Yi, Q. S. (2014). Environmental friendly cutting fluids and cooling techniques in machining: A review. Journal of Cleaner Production, 83, 33–47. https://doi.org/10.1016/j.jclepro.2014.07.071

Jiugen, W., & Jianzhong, Z. (2005). On formation and breakup of boundary lubricating layer. Lubrication Engineering-Huangpu-, 6(172), 4

Giakoumis, E. G. (2018). Analysis of 22 vegetable oils’ physico-chemical properties and fatty acid composition on a statistical basis, and correlation with the degree of unsaturation. Renewable Energy, 126, 403–419

Abdalla, H., & Patel, S. (2006). The performance and oxidation stability of sustainable metalworking fluid derived from vegetable extracts. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 220(12), 2027–2040

Hu, Z. (1999). Study on tribology of hydroxy and sulfurized vegetable oil fatty acids. Shanghai University Press.

Baumgart, P., Canzi, G., Hanashiro, T., Doezema, L. A., & Siniawski, M. T. (2010). Influence of fatty acid additives on the tribological performance of sunflower oil. Lubrication Science, 22(9), 393–403

Guo, S., Li, C., Zhang, Y., Wang, Y., Li, B., Yang, M., et al. (2017). Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. Journal of Cleaner Production, 140, 1060–1076

Fox, N., Tyrer, B., & Stachowiak, G. (2004). Boundary lubrication performance of free fatty acids in sunflower oil. Tribology Letters, 16(4), 275–281

Zhang, Y., Li, C., Yang, M., Jia, D., Wang, Y., Li, B., et al. (2016). Experimental evaluation of cooling performance by friction coefficient and specific friction energy in nanofluid minimum quantity lubrication grinding with different types of vegetable oil. Journal of Cleaner Production, 139, 685–705

Sahoo, A. K., & Sahoo, B. (2012). Experimental investigations on machinability aspects in finish hard turning of AISI 4340 steel using uncoated and multilayer coated carbide inserts. Measurement, 45(8), 2153–2165

Shokoohi, Y., Khosrojerdi, E., & Shiadhi, B. R. (2015). Machining and ecological effects of a new developed cutting fluid in combination with different cooling techniques on turning operation. Journal of Cleaner Production, 94, 330–339

Ravi, S., & Kumar, M. P. (2011). Experimental investigations on cryogenic cooling by liquid nitrogen in the end milling of hardened steel. Cryogenics, 51(9), 509–515

Yi, S., Li, G., Ding, S., & Mo, J. (2017). Performance and mechanisms of graphene oxide suspended cutting fluid in the drilling of titanium alloy Ti-6Al-4V. Journal of Manufacturing Processes, 29, 182–193

da Silva, L. R., Bianchi, E. C., Fusse, R. Y., Catai, R. E., Franca, T. V., & Aguiar, P. R. (2007). Analysis of surface integrity for minimum quantity lubricant—MQL in grinding. International Journal of Machine Tools and Manufacture, 47(2), 412–418

Khaliq, W., Zhang, C., Jamil, M., & Khan, A. M. (2020). Tool wear, surface quality, and residual stresses analysis of micro-machined additive manufactured Ti–6Al–4V under dry and MQL conditions. Tribology International, 151, 106408. https://doi.org/10.1016/j.triboint.2020.106408

Guo, S., Li, C., Zhang, Y., Yang, M., Jia, D., Zhang, X., et al. (2018). Analysis of volume ratio of castor/soybean oil mixture on minimum quantity lubrication grinding performance and microstructure evaluation by fractal dimension. Industrial Crops and Products, 111, 494–505. https://doi.org/10.1016/j.indcrop.2017.11.024

Shukla, A., Kotwani, A., & Unune, D. R. (2020). Performance comparison of dry, flood and vegetable oil based minimum quantity lubrication environments during CNC milling of Aluminium 6061. Materials Today: Proceedings, 21, 1483–1488

Cao, T., Liu, Y., & Xu, Y. (2020). Cutting performance of tool with continuous lubrication at tool-chip interface. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(2), 347–359. https://doi.org/10.1007/s40684-019-00114-4

Sidik, N. A. C., Samion, S., Ghaderian, J., & Yazid, M. N. A. W. M. (2017). Recent progress on the application of nanofluids in minimum quantity lubrication machining: A review. International Journal of Heat and Mass Transfer, 108, 79–89

Sen, B., Mia, M., Mandal, U. K., Dutta, B., & Mondal, S. P. (2019). Multi-objective optimization for MQL-assisted end milling operation: An intelligent hybrid strategy combining GEP and NTOPSIS. Neural Computing and Applications, 31(12), 8693–8717

Singh, H., Sharma, V. S., & Dogra, M. (2020). Exploration of graphene assisted vegetables oil based minimum quantity lubrication for surface grinding of TI-6AL-4V-ELI. Tribology International, 144, 106113

Chetan Behera, B. C., Ghosh, S., & Rao, P. V. (2016). Wear behavior of PVD TiN coated carbide inserts during machining of Nimonic 90 and Ti6Al4V superalloys under dry and MQL conditions. Ceramics International, 42(13), 14873–14885. https://doi.org/10.1016/j.ceramint.2016.06.124

Author information

Authors and Affiliations

Contributions

All the authors have equally participated and worked as a team to complete this research work. The major contribution of the authors is listed as: AP: Problem formulation, related literature review, fabrication of the experimental set-up and procurement of material, conducting of experimentation, testing, analysis of the results and writing—original draft are the major contribution of the AP. SSC, HSS: Discussion on the idea, help in the procurement and arranging of the facilities, conducting of experimentation, analysis of the results, writing—review and editing and whole process monitoring are the major contributions of the SSC and HSS.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pal, A., Chatha, S.S. & Sidhu, H.S. Performance Evaluation of Various Vegetable Oils and Distilled Water as Base Fluids Using Eco-friendly MQL Technique in Drilling of AISI 321 Stainless Steel. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 745–764 (2022). https://doi.org/10.1007/s40684-021-00355-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00355-2