Abstract

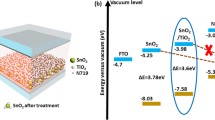

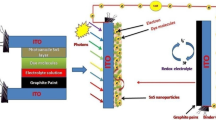

This paper reports the performance of alizarin based SnO2 dye-sensitized solar cells. A novel template assisted method has been applied for the preparation of tin oxide nanoparticles. For the first time, onion (Allium cepa) was used as a template for the synthesis of tin oxide nanostructures at different pH values. Tin oxide nanostructures were used for the photoanode preparation. A sandwich cell was prepared by using the dye soaked SnO2 film as a photoanode and platinum as a counter electrode. The structural, morphological and optical properties of the nanoparticles were studied using powder X-ray diffraction (XRD), Scanning Electron microscope (SEM), Photoluminescence (PL), Attenuated Total Reflectance (ATR) spectra and UV–visible spectroscopic techniques. Current–voltage (I–V) characteristics have been measured using electrochemical workstation under the presence of solar illumination. Characteristic parameters of the fabricated cell were determined on the basis of the measured I–V curves.

Similar content being viewed by others

References

B. O’Regan, M. Gratzel, Nature (1991). https://doi.org/10.1038/353737a0

W. Qarony, M.I. Hossain, M.K. Hossain, M.J. Uddin, A. Haque, A.R. Saad, Y.H. Tsang, Results Phys. (2017). https://doi.org/10.1016/j.rinp.2017.09.030

A. Aboulouard, B. Gultekin, M. Can, M. Erol, A. Jouaiti, B. Elhadadi, C. Zafer, S. Demic, J. Mater. Res. Technol (2020). https://doi.org/10.1016/j.jmrt.2019.11.083

R.P.A. Latini, IdaPettiti, Carmen Cavallo. Mater. Chem. Phys. (2017). https://doi.org/10.1016/j.matchemphys.2017.09.030

I. Iwantono, S.K.M. Saad, R. Yuda, M.Y. Abd Rahman, A.A. Umar, Superlattices Microstruct. (2018). https://doi.org/10.1016/j.spmi.2018.05.041

A. Rajendran, S. Kandasamy, Mater. Res. Innov. (2019). https://doi.org/10.1080/14328917.2017.1349060

A.N. Kawade, P.K. Bhujbal, A.T. Supekar, H.M. Pathan, K.M. Sonawane, Optik (2020). https://doi.org/10.1016/j.ijleo.2020.164968

T. Krishnamoorthy, M.Z. Tang, A. Verma, A.S. Nair, D. Pliszka, S.G. Mhaisalkar, S. Ramakrishna, J. Mater. Chem. (2012). https://doi.org/10.1039/C1JM15047B

M.K. Hossain, M.F. Pervez, S. Tayyaba, M.J. Uddin, A.A. Mortuza, M.N.H. Mia, M.A. Khan, Efficiency enhancement of natural dye sensitized solar cell by optimizing electrode fabrication parameters. Mater. Sci. 35, 816–823 (2017)

G. Syrrokostas, A. Siokou, G. Leftheriotis, P. Yianoulis, Sol. Energy Mater. Sol. Cells (2012). https://doi.org/10.1016/j.solmat.2012.04.021

A. Ramachandran, C.O. Sreekala, K.S. Sreelatha, I. Jinchu, IOP Conf. Series: Mater. Sci Eng. (2018). https://doi.org/10.1088/1757-899X/310/1/012151

H.K. Farag, H. Abbas, Z. Phys. Chem. (2018). https://doi.org/10.1515/zpch-2017-0966

J.F. Mohammad, M.A.A. Sooud, S.M. Abed, J. Ovonic Res. 16(2), 107–113 (2020)

K. Vignesh, R. Hariharan, M. Rajarajan, A. Suganthi, Solid State Sci. (2013). https://doi.org/10.1016/j.solidstatesciences.2013.04.017

R.C. Abruzzi, B.A. Dedavid, M.J.R. Pire, Cerâmica (2015). https://doi.org/10.1590/0366-69132015613591919

S. Tazikeh, A. Akbari, A. Talebi, E. Talebi, Mater. Sci-Poland (2014). https://doi.org/10.2478/s13536-013-0164-y

H. Yang, Y. Hu, A. Tang, S. Jin, G. Qiu, J. Alloy Compds. 363(1–2), 276–279 (2004). https://doi.org/10.1016/S0925-8388(03)00473-0

A.G. Habte, F.G. Hone, F.B. Dejene, Physica B Condens. Matter. (2020). https://doi.org/10.1016/j.physb.2019.411832

S. Jayapandi, P. Packiyaraj, S. Premkumar, J. Mayandi, K. Anitha, Ionics (2017). https://doi.org/10.1007/s11581-017-2121-y

W. Peng, X. Yang, Z. Chen, J. Zhang, H. Chen, K. Zhang, L. Han, Chemsuschem (2014). https://doi.org/10.1002/cssc.201300644

M.A. Gondal, Q.A. Drmosh, T.A. Saleh, Appl. Surface Sci. (2010). https://doi.org/10.1016/j.apsusc.2010.05.027

B. Nandan, B. Venugopal, S. Amirthapandian, B.K. Panigrahi, P. Thangadurai, J. Nanopart. Res. (2013). https://doi.org/10.1007/s11051-013-1999-1

S. Sain, A. Kar, A.P. Swapan, K. Pradhan, CrystEngComm (2014). https://doi.org/10.1039/c3ce42281j

R. Vasanthapriya, N. Neelakandeswari, N. Rajasekaran, K. Uthayarani, M. Chitra, Mater. Lett. (2018). https://doi.org/10.1016/j.matlet.2018.02.118

K.G. Godinho, A. Walsh, G.W. Watson, J. Phys. Chem. C (2009). https://doi.org/10.1021/jp807753t

L.B. Patle, A.L. Chaudhari, Int. J. Sci. Eng. Res. 7(8), 1004–1009 (2016)

C.O. Sreekala, R. Pragash, K.S. Sreelatha, I. Jinchu, 2017 IEEE International Conference on Technological Advancements in Power and Energy (TAP Energy)

T. Qi, QianWang, Yongchao Zhang, DiWang, Renqiang Yang, Wei Zheng. Mater. Des. (2016). https://doi.org/10.1016/j.matdes.2016.09.098

S.A. Arote, V.A. Tabhane, H.M. Pathan, Opt. Mater. (2018). https://doi.org/10.1016/j.optmat.2017.11.023

Funding

Authors wish to thank DST, India for creating characterisation facilities under DST-FIST(SR/FST/COLLEGE-154/2013 scheme in Sri Ramakrishna Engineering College, Coimbatore, Tamilnadu, India).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vasanthapriya, R., Neelakandeswari, N., Uthayarani, K. et al. Influence of pH on the DSSC Performance of Template Assisted SnO2 Nanostructures. J Inorg Organomet Polym 31, 4272–4280 (2021). https://doi.org/10.1007/s10904-021-02031-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-021-02031-z