Abstract—

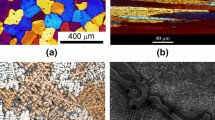

Many algorithms that are capable of determining the indent area in automatic processing of optical images of imprints have found application in hardness measurements using the Vickers method. A robust interactive algorithm based on the maximum separation of color image components in the indentation area and an unstrained surface is described. The efficiency and stability of the presented method are evaluated using indents on several materials with different morphology and deformation character.

Similar content being viewed by others

REFERENCES

GOST R ISO (State Standard) no. 6507-1-2007: Metals and Alloys. Vickers Hardness Test. Part 1. Test Method, Moscow: Standartinform, 2008.

ISO no. 6507-1:2005: Metallic Materials - Vickers Hardness Test, 2005.

Baldner, F., Costa, P.B., Gomes, J.F.S., and Leta, F.R., in Advances in Visualization and Optimization Techniques for Multidisciplinary Research, Vucinic, D., Leta, F.R., and Janardhanan, S., Eds., Singapore: Springer, 2019, pp. 265−281. https://doi.org/10.1007/978-981-13-9806-3_9.

Gadermayr, M., Maier, A., and Uhl, A., Mach. Vision Appl., 2013, vol. 24, no. 6, p. 1183. https://doi.org/10.1007/s00138-012-0478-5

Oliver, W.C. and Pharr, G.M., J. Mater. Res., 2004, vol. 19, no. 1, p. 3. https://doi.org/10.1557/jmr.2004.19.1.3

Dominguez-Nicolás, M., Herrera-May, A.L., García-González, L., Zamora, L., Hernández-Torres, J., Martínez-Castillo, J., Morales-Gonzalez, E., Cerón-Alvarezand, C.A., and Escobar-Pére, A., Meas. Sci. Technol., 2020, vol. 32, no. 1, p. 015407. https://doi.org/10.1088/1361-6501/abaa66

Aminzadeh, M. and Kurfess, T., J. Manuf. Syst., 2015, vol. 37, p. 83. https://doi.org/10.1016/j.jmsy.2015.09.004

Truong, M.T.N. and Kim, S., Soft Comput., 2018, vol. 22, no. 13, p. 4197. https://doi.org/10.1007/s00500-017-2709-1

Wakaf, Z. and Jalab, H.A., J. King Saud Univ. − Comput. Inf. Sci., 2018, vol. 30, no. 1, p. 33. https://doi.org/10.1016/j.jksuci.2016.11.001

Firdousi, R. and Parveen, S., Int. J. Eng. Comput. Sci., 2014, vol. 3, no. 3, p. 4062. http://103.53.42.157/index.php/ijecs/article/view/152.

Yong Pan, Yuekang Shan, Yu Ji, and Shibo Zhang, Proc. 4th Int. Symposium on Precision Mechanical Measurements, Anhui, December 31, 2008, 71304C, pp. 998–1003.

Yao, L. and Chih-Heng Fang, IEEE Trans. Ind. Electron., 2006, vol. 53, no. 3, p. 950. https://doi.org/10.1109/TIE.2006.874259

Funding

The study was supported by the Russian Foundation for Basic Research, scientific project no. 18-08-00558.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Goryacheva

Rights and permissions

About this article

Cite this article

Fedotkin, A.P., Laktionov, I.V., Kravchuk, K.S. et al. Automatic Processing of Microhardness Images Using Computer Vision Methods. Instrum Exp Tech 64, 357–362 (2021). https://doi.org/10.1134/S0020441221030180

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441221030180