Abstract—

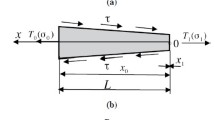

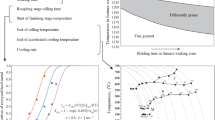

According to research tests, the rolling-and-drawing of metal in nondriven rollers reduces the rolling force by 30 to 32% as compared with the rolling in driven rollers. A new method of determining the friction coefficient for a modified process flow sheet is proposed. As shown by the calculations, continuous strip mills used in the roll-and-draw mode cut the metal strain force by 34 to 41% and the energy costs of strip rolling by 5 to 13%.

Similar content being viewed by others

REFERENCES

Polukhin, P.I., Polukhin, V.P., Pimenov, A.F., et al., Prokatka na mnogovalkovykh stanakh (Rolling on Multi-Roll Mills), Moscow: Metallurgiya, 1981.

Garber, E.A., Stany kholodnoi prokatki (teoriya, oborudovanie, tekhnologiya) (Cold-Rolling Mills: Theory, Equipment, and Technology), Moscow: Chermetinformatsiya, 2004.

Perlin, I.Ya. and Ermanyuk, M.Z., Teoriya volocheniya (Theory of Drawing), Moscow: Metallurgiya, 1971.

Dobrov, I.V., Analysis of the influence of the external friction coefficient on the parameters of the drawing process in roller dies, Nauk, Visti Suchasni Probl. Metal., 2005, no. 8, pp. 131–135.

Dobrov, I.V., Grudev, A.P., and Kokovikhin, Yu.V., Comparative analysis of rolling and drawing processes in roller dies, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1987, no. 10, pp. 44–48.

Lokhomatov, A.P., Zhuchkov, S.M., Kulakov, L.V., et al., Nepreryvnaya prokatka sortovoi stali (Continuous Rolling of Bar Steel), Kyiv: Naukova Dumka, 1998.

Nikolaev, V.A., Determination of kinematic and energy-power parameters of rolling with a single-roll drive, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1993, no. 1, pp. 34–37.

Nikolaev, V.A., Teoriya i praktika protsessov prokatki (The Theory and Practice of Rolling Processes), Zaporozhye: Zaporozh. Gos. Inzh. Akad., 2002.

Nikolaev, V.A., Vasil’ev, A.G., and Vasil’ev, A.A., Parameters of rolling-drawing of thin strips in non-drive rolls, Metall. Gornorudn. Prom-st., 2009, no. 5, pp. 50–53.

Nikolaev, V.A., Issledovanie paramtrov, sposoby i ustroistva prkatki polos (Study of Parameters, Methods, and Devices of the Metal Strip Rolling), Zaporozhye: Aktsent Invest-Treid, 2012.

Nikolaev, V.A., Average normal contact stress and other parameters during rolling of thin strips, Stal’, 2016, no. 2, pp. 27–29.

Polukhin, P.I., Nikolaev, V.A., Polukhin, V.P., et al., Kontaktnoe vzaimodeistvie metalla i instrumenta pri prokatke (Contact Interaction of Metal and Tool during Rolling), Moscow: Metallurgiya, 1974.

Nikolaev, V.A., Determination of torque during rolling in a quarto cage, Stal’, 2016, no. 7, pp. 40–43.

Nikolaev, V.A. and Vasil’ev, A.G., Rolling parameters of strips with opposite roll displacement, Stal’, 2019, no. 10, pp. 27–31.

Nikolaev, V.A. and Putnoki, A.Yu., Prokatka shirokopolosnoi stali (Rolling of Broad-Strip Steel), Kiev: Osvita Ukrainy, 2009.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Kuznetsov

About this article

Cite this article

Nikolaev, V.A., Vasilyev, A.A. & Vasilyev, A.G. Rolling in Nondriven Rollers of Four-High Mill Stands. Steel Transl. 51, 125–130 (2021). https://doi.org/10.3103/S0967091221020078

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221020078