Abstract

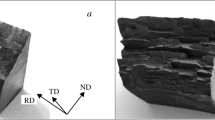

The influence of three multipass cross rolling patterns on the microstructure, mechanical properties and fracture toughness of ferrite-pearlitic pipe steel 09G2S is investigated using mechanical testing, optical metallography, transmission and scanning electron microscopy. Upon all cross-rolling patterns, a change in the parameters of the initial workpiece grain structure is observed with the formation of layered grain size distribution. Near the workpiece surface, the size of globular grains is 1–4 μm, the length of elongated grains in the central part of the workpiece varies from units to tens of μm, and the width varies from 1 to 8 μm. Mechanical tests for uniaxial tension and impact strength are carried out on specimens machined from the central part of the bar. It is established that cross rolling leads to an increase in the yield point and ultimate strength of steel after all investigated patterns with a slight decrease in the overall plasticity. The greatest increase in impact toughness at T = –70°C is observed after controlled cross rolling in the temperature range 850–500°C. Using electron microscopic studies, it is shown that the mechanical behavior of the cross-rolled specimens is associated with structural transformations that occur in steel during rolling and cooling. The main strengthening factor is the refinement of ferrite grains and the formation of a subgrain structure as cross rolled. The increase in impact toughness is associated with a more uniform finely dispersed structure of rolled products, which does not contain cementite and bainite plates. Temperature dependent fracture processes of the initial cross-rolled steel specimens are analyzed based on recorded shock loading diagrams and structures in the rupture areas of Charpy specimens.

Similar content being viewed by others

REFERENCES

Rybin, V.V., Malyshevskii, V.A., and Khlusova, E.I., Structure and properties of cold resistant steels for northern operating, Vopr. Materialoved., 2006, no. 1 (45), pp. 24–44.

Gorynin, I.V., Rybin, V.V., Malyshevskii, V.A., and Khlusova, E.I., Cold-resistant steels for Arctic shelf development equipment, Vopr. Materialoved., 2009, no. 3 (59), pp. 108–126.

Chzhao, F. and Chzhao, L., Bainitic steels with ultra-low carbon content and prospects for their application, Vopr. Materialoved., 2008, no. 1 (53), pp. 52–61.

Tian, Y., Wang, H.T., Wang, Z.D., Misra, R.D.K., and Wang, G.D., Microstructural evolution and the precipitation behavior in X90 linepipe steel during isothermal processing, J. Mater. Eng. Perform., 2018, vol. 27, no. 4, pp. 1494–1504. https://doi.org/10.1007/s11665-018-3197-x

Mishin, I.P., Naydenkin, E.V., Ratochka, I.V., Lykova, O.N., and Manisheva, A.I., Study of the effect of combined rolling with subsequent aging on structure and mechanical properties of near β titanium alloy, AIP Conf. Proc., 2019, vol. 2167, art. ID 020230. https://doi.org/10.1063/1.5132097

Naizabekov, A.B., Leznev, S.N., and Arbuz, A.S., The effect of radial-shear rolling on the microstructure and mechanical properties of technical titanium, Solid State Phenom., 2020, vol. 299, pp. 565–570. https://doi.org/10.4028/www.scientific.net/SSP.299.565

Ivanov, K.V., Naidenkin, E.V., Lykova, O.N., Ratochka, I.V., Mishin, I.P., and Vinokurov, V.A., Structure evolution and mechanical properties of a Ti-6Al-4V alloy during helical rolling and subsequent deformation and heat treatments, Russ. Phys. J., 2017, vol. 60, no. 7, pp. 1226–1232. https://doi.org/10.1007/s11182-017-1199-z

Surikova, N.S., Panin, V.E., Narkevich, N.A., Mishin, I.P., and Gordienko, A.I., Formation of a multilevel hierarchical mesosubstructure by cross rolling and its influence on the mechanical behavior of austenitic steel, Phys. Mesomech., 2018, vol. 21, no. 5, pp. 430–440. https://doi.org/10.1134/S1029959918050077

Gorelik, S.S., Dobatkin, S.V., and Kaputkina, L.M., Rekristallizatsiya metallov i splavov (Recrystallization of Metals and Alloys), Moscow: Mosk. Inst. Stali Splavov, 2005.

Schastlivtsev, V.M., Tabachnikova, T.I., Yakovleva, I.L., Kruglova, A.A., Khlusova, E.I., and Orlov, V.V., Features of bainite structure in low-carbon welded steels after thermomechanical treatment, Vopr. Materialoved., 2009, no. 3 (59), pp. 26–38.

Hu, J., Du, L.-X., Xie, H., Yu, P., and Misra, R.D.K., A nanograined/ultrafine-grained low-carbon microalloyed steel processed by warm rolling, Mater. Sci. Eng., A, 2014, vol. 605, pp. 186–191. https://doi.org/10.1016/j.msea.2014.03.064

Hohenwarter, A., Kapp, M.W., Volker, B., Renk, O., and Pippan, R., Strength and ductility of heavily deformed pearlitic microstructures, IOP Conf. Ser.: Mater. Sci. Eng., 2017, vol. 219, art. ID 012003. https://doi.org/10.1088/1757-899X/219/1/012003

Li, Y.J., Kang, J., Zhang, W.N., Liu, D., Wang, X.H., Yuan, G., Misra, R.D.K., and Wang, G.D., A novel phase transition behavior during dynamic partitioning and analysis of retained austenite in quenched and partitioned steels, Mater. Sci. Eng., A, 2018, vol. 710, pp. 181–191. https://doi.org/10.1016/j.msea.2017.10.104

Schastlivtsev, V.M., Yakovleva, I.L., Tereshchenko, N.A., Kurban, V.V., Kornilov, V.L., Salganik, V.M., and Pesin, A.M., Main structural factors of strengthening of low-carbon low-alloy pipe steels after controlled rolling, Met. Sci. Heat Treat., 2009, vol. 51, nos. 1–2, pp. 40–44.

Ghosh, S. and Mula, S., Thermomechanical processing of low carbon Nb–Ti stabilized microalloyed steel: microstructure and mechanical properties, Mater. Sci. Eng., A, 2015, vol. 646, pp. 218–233. https://doi.org/10.1016/j.msea.2015.08.072

Tian, J., Xu, G., Liang, W., and Yuan, Q., Effect of annealing on the microstructure and mechanical properties of low-carbon steel with ultrafine grains, Metallogr., Microstruct. Anal., 2017, vol. 6, no. 3, pp. 233–239. https://doi.org/10.1007/s13632-017-0350-0

Ravi, A.M., Kumar, A., Herbi, M., Sietsma, J., and Santofimia, M.J., Impact of austenite grain boundaries and ferrite nucleation on bainite formation in steels, Acta Mater., 2020, vol. 188, pp. 424–434. https://doi.org/10.1016/j.actamat.2020.01.065

Shamsujjoha, M., Evolution of microstructures, dislocation density and arrangement during deformation of low carbon lath martensitic steels, Mater. Sci. Eng., A, 2020, vol. 776, art. ID 139039. https://doi.org/10.1016/j.msea.2020.139039

Eres-Castellanos, A., Caballero, F.G., and Garcia-Mateo, C., Stress or strain induced martensitic and bainitic transformations during ausforming processes, Acta Mater., 2020, vol. 189, pp. 60–72. https://doi.org/10.1016/j.actamat.2020.03.002

Yakovleva, S.P., Makharova, S.N., and Borisova, M.Z., Structure, properties, and fracture of a low-alloy steel in the submicrocrystalline state, Russ. Metall. (Engl. Transl.), 2006, vol. 2006, no. 4, pp. 337–343.

Farber, V.M., Khotinov, V.A., Morozova, A.N., Lezhnin, N.V., and Martin, T., Diagnosis of fractures and energy intensity of viscous fracture during instrumental tests for impact bending, Met. Sci. Heat Treat., 2015, vol. 57, nos. 5–6, pp. 329–333.

Khotinov, V.A., Faber, V.M., and Morozova, A.N., Evaluating the toughness of pipe steels by impact fracture curves, Diagn., Resour. Mech. Mater. Struct., 2015, no. 2, pp. 57–66.

Faber, V.M., Khotinov, V.A., Morozova, A.N., Selivanova, O.V., Polukhina, O.N., and Karabanalov, M.S., Study of the breakage region of high ductility steel 08G2B Charpy specimen fracture, Met. Sci. Heat Treat., 2018, vol. 60, nos. 5–6, pp. 348–353. https://doi.org/10.1007/s11041-018-0282-6

Funding

This work was carried out within the framework of the state assignment of the Institute of Strength Physics and Materials Science, Siberian Branch of the Russian Academy of Sciences, topic no. FWRW–2021–0010, and with the financial support of the Russian Foundation for Basic Research within the framework of scientific project no. 18-08-00221.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Surikova, N.S., Vlasov, I.V., Derevyagina, L.S. et al. Influence of Cross Rolling Patterns on the Mechanical Properties and Fracture Toughness of Pipe Steel. Steel Transl. 51, 7–14 (2021). https://doi.org/10.3103/S0967091221010113

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091221010113