Abstract

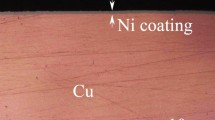

The solid–liquid compound casting (SLCC) was used to produce Ti/Mg bimetal via hot dip Zn coating, and the interfacial microstructures and mechanical properties of the Mg/Ti bimetal were investigated in this work. The scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS) reveal that there is no interlayer metallurgical reaction when the pouring temperature is 670 °C. As the pouring temperature increases to 710 and 750 °C, the thickness of the metallurgical interfacial zone is about 130 and 310 µm, respectively. The interfacial zone is mainly consists of α-Mg and τ-TiAlZn coexistence phases. Thermodynamic models are established to explain the evolution mechanism of α-Mg and τ-TiAlZn coexistence phases. It is concluded that the formation process of α-Mg and τ-TiAlZn phase coexist is as follows: TiZn5(s)-to-TiZn5(l), and then α-Mg and τ-TiAlZn phases coexist. While the sequence of the phases that formed in the Ti–Al–Zn ternary system is TiAl3→τ-TiAlZn, this is based on the fact that the Al atoms are used up at the interfacial zone. The highest shear strength of Zn-coated TC4/AZ91D bimetallic material is up to 34.24 Mpa when the pouring temperature is 710 °C.

Similar content being viewed by others

References

T.E.B.L. Mordike, Mater Sci Eng A 1, 37–45 (2001)

M.K. Kulekci, Int J Adv Manuf Tech 39, 851–865 (2007)

X. Lu, G. Zhao, H. Xi, C. Zhang, L. Chen, L. Sun, Mater Charact 151, 414–428 (2019)

E. Karakulak, J Magn Alloy 3, 355–369 (2019)

J. Yao, Y. Wang, G. Wu, M. Sun, M. Wang, Q. Zhang, Appl Surf Sci 479, 727–737 (2019)

Y. Sun, G. Luo, J. Zhang, C. Wu, J. Li, Q. Shen, L. Zhang, J Alloy Compd 741, 918–926 (2018)

M. Aonuma, K. Nakata, Mater Sci Eng: B 161, 46–49 (2009)

A.M. Atieh, T.I. Khan, J. Mat. S 48, 6737–6745 (2013)

A.M. Atieh, T.I. Khan, J Mater Process Technol 214, 3158–3168 (2014)

A. AlHazaa, I. Alhoweml, M.A. Shar, M. Hezam, H.S. Abdo, H. AlBrithen, Materials 12, 769 (2019)

R. Cao, T. Wang, C. Wang, Z. Feng, Q. Lin, J.H. Chen, J Alloy Compd 605, 12–20 (2014)

C. Xu, G. Sheng, H. Wang, K. Feng, X. Yuan, J Mater Sci Tech 32, 167–171 (2016)

M. Gao, Z.M. Wang, X.Y. Li, X.Y. Zeng, MMTA 43, 163–172 (2011)

C. Tan, X. Song, B. Chen, L. Li, J. Feng, Mater Lett 167, 38–42 (2016)

C. Tan, B. Chen, S. Meng, K. Zhang, X. Song, L. Zhou, J. Feng, Mater Design 99, 127–134 (2016)

M. Pintore, J. Wölck, T. Mittler, T. Gress, B. Tonn, W. Volk, Int J Metalcast 14, 155–166 (2020). https://doi.org/10.1007/s40962-019-00344-x

T. Greß, V. Glück Nardi, T. Mittler, S. Schmid, P. Buchberger, B. Tonn, W. Volk, Int J Metalcast 14, 564–579 (2020). https://doi.org/10.1007/s40962-019-00387-0

A.O. Bakke, L. Arnberg, Y.J. Li, J.O.E. Loland, S. Jorgensen, J. Kvinge, Int J Metalcast 1, 40–48 (2019)

M. Pintore, O. Starykov, T. Mittler, W. Volk, B. Tonn, Int J Metalcast 12, 79–88 (2018). https://doi.org/10.1007/s40962-017-0140-0

J. Cheng, J. Zhao, D. Zheng, J.-J. Shang-guan, K. He, Y. Guo, Int J Metalcast 14, 518–527 (2020). https://doi.org/10.1007/s40962-019-00380-7

W.M. Jiang, Z.T. Fan, C. Li, J Mater Process Technol 226, 25–31 (2015)

K. Bobzin, M. Öte, S. Wiesner, L. Gerdt, A. Buehrig-Polaczek, J. Brachmann, Int J Metalcast 12, 712–721 (2018). https://doi.org/10.1007/s40962-017-0205-0

Z. Jiang, Z. Fan, W. Jiang, G. Li, Y. Wu, F. Guan, H. Jiang, J Mater Process Technol 261, 149–158 (2018)

E. Hajjari, M. Divandari, S.H. Razavi, S.M. Emami, T. Homma, S. Kamado, JMatS 46, 6491–6499 (2011)

K. He, J. Zhao, P. Li, J. He, Q. Tang, Mater Design 112, 553–564 (2016)

J. Cheng, J. H. Zhao, J. Y. Zhang, Y. Guo, K. He, J. J. Shang-Guan and F. L. Wen, Materials 12, 1651 (2019)

J.L. Murray, Bull Alloy phase Diagram 7, 245–248 (1986)

C.T. Chang, R.K. Shiue, Int J Refract Met Hard Mater 23, 161–170 (2005)

Y. Hu, Y. Xiong, X. Chen, H. Bai, Y. Tian, G. Liu, Appl Opt 57, 4277–4282 (2018)

A.M. Atieh, T.I. Khan, JMatS 49, 7648–7658 (2014)

C. Tan, C. Zang, X. Zhao, H. Xia, Q. Lu, X. Song, B. Chen, G. Wang, Opt. Laser Technol. 108, 378–391 (2018)

A.M. Atieh, T.I. Khan, J Mater Eng Perform 23, 4042–4054 (2014)

A.N. AlHazaa, Key Eng Mater 735, 34–41 (2017)

K. He, J. Zhao, J. Cheng, J. Shangguan, F. Wen and Y. Wang, Materials (Basel) 12 (2019)

G. Ghosh, S. Delsante, G. Borzone, M. Asta, R. Ferro, Acta Mater 54, 4977–4997 (2006)

G.P. Vassilev, E.S. Dobrev, J.C. Tedenac, J Alloy Compd 407, 170–175 (2006)

D.A. Brice, P. Samimi, I. Ghamarian, Y. Liu, M.Y. Mendoza, M.J. Kenney, R.F. Reidy, M. Garcia-Avila, P.C. Collins, J Alloy Compd 718, 22–27 (2017)

X.J.L.G.P. Vassilev, K. Ishida, J Alloy Compd 384, 162–170 (2004)

R. Miedema, P.F. Chatel, F.R. Boer, Phys B 100(1), 1–28 (1980)

G.W. Toop, Trans Metall Soc AIME 233, 850–854 (1965)

S. Yang, X. Su, J. Wang, F. Yin, Z. Li, H. Tu, H. Peng, J Alloy Compd 499, 194–199 (2010)

Q. Luo, Q. Li, F. Jin, J.-Y. Zhang, X.-B. Yu, Q.-F. Gu, K.-C. Chou, Intermetallics 26, 136–141 (2012)

S.-M. Liang, H.K. Singh, H. Zhang, R. Schmid-Fetzer, Calphad 64, 213–224 (2019)

J.-H. Zhao, Y.-Q. Zhang, J.-S. He, P. Li, Surf Coat Tech 307, 301–307 (2016)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51875062).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shangguan, J., Zhao, J., Shi, Y. et al. Effects of Zn Interlayer on Microstructures and Mechanical Properties of TC4/AZ91D Bimetal via Solid–Liquid Compound Casting Process. Inter Metalcast 16, 419–434 (2022). https://doi.org/10.1007/s40962-021-00612-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00612-9