Abstract

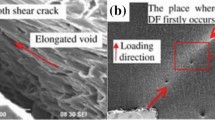

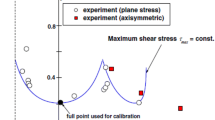

This paper is concerned with accurate prediction on the fracture strain and fracture forming limit curve (FFLC) by calibrating the material constants by the specimens with reasonable shapes and sizes. The Lou–Huh ductile fracture criteria (DFC) in analytic and integral forms were adopted, and the theoretical formulas in various stress states were derived. The process and basis for calibrating the material constants of DFC by hybrid experimental–numerical method were described in detail. Moreover, the material constants calculated by different test groups including the uniaxial tensile, plane strain and shear specimens with different shapes and sizes vary enormously, and the optimal test group was determined to calibrate the material constant of DFC. Meanwhile, it can be found that the different material constants greatly impact on the magnitude and shape of the fracture strain and FFLC, and the effect of each material constant on the fracture strain and FFLC was analyzed and compared in this paper. Finally, the FFLCs theoretically calculated by DFC in analytic and integral forms were verified by the experimental forming limiting data of the bulge test.

Graphic Abstract

Similar content being viewed by others

References

W. Muhammad, A.P. Brahme, R.K. Sabat, R.K. Mishra, K. Inal. Mater. Sci. Eng. A 759, 613 (2019)

Z.Y. Cai, S.H. Wang, X.D. Xu, M.Z. Li, J. Mater. Process. Tech. 209, 396 (2009)

M. Scales, K. Chen, S. Kyriakides, Int. J. Plasticity 120, 340 (2019)

Z.Y. Cai, S.H. Wang, M.Z. Li, Int. J. Adv. Manuf. Tech. 37, 927 (2008)

J. Cao, F.G. Li, X.K. Ma, Z.k. Sun, Int. J. Mech. Sci. 128–129, 445 (2017)

F. Djavanroodi, M. Ebrahimi, M. Janbakhsh, Results Phys. 14, 102496 (2019)

T. Wierzbicki, Y.B. Bao, Y.W. Lee, Y.l. Bai, Int. J. Mech. Sci. 47, 719 (2005)

M.G. Cockcroft, D.J. Latham, J. I. Met. 96, 33 (1968)

G.R. Johnson, W.H. Cook, Eng. Fract. Mech. 21, 31 (1985)

S.E. Clift, P. Hartley, C.E.N. Sturgess, G.W. Rowe, Int. J. Mech. Sci. 32, 1 (1990)

Y.K. Ko, J.S. Lee, H. Huh, H.K. Kim, S.H. Park, J. Mater. Process. Tech. 187–188, 358 (2007)

Y.S. Kim, S.H. Yang, Chin. J. Mech. Eng. 30, 625 (2017)

Y.L. Bai, T. Wierzbicki, Int. J. Fracture 161, 1 (2010)

Y.S. Lou, H. Huh, S. Lim, K. Pack, Int. J. Solids Struct. 49, 3605 (2012)

Y.S. Lou, H. Huh, J. Mater. Process. Tech. 213, 1284 (2013)

Y.B. Bao, T. Wierzbicki, Int. J. Mech. Sci. 46, 81 (2004)

L. Malcher, F.M. Andrade Pires, J.M.A. César de Sá, Int. J. Plasticity 54, 193 (2014)

Y.S. Lou, H. Huh, Int. J. Solids Struct. 50, 447 (2013)

Y.L. Bai, T. Wierzbicki, Int. J. Plasticity 24, 1071 (2008)

Y.B. Bao, T. Wierzbicki, Eng. Fract. Mech. 72, 1049 (2005)

M. Brunig, S. Gerke, M. Schmidt, Int. J. Plasticity 102, 70 (2018)

X. Teng, T. Wierzbicki, Eng. Fract. Mech. 73, 1653 (2006)

M.J. Mirnia, M. Vahdani, J. Mater. Process. Tech. 280, 116589 (2020)

H. Talebi-Ghadikolaee, H.M. Naeini, M.J. Mirnia, M.A. Mirzai, S. Alexandrov, M.S. Zeinali, J. Mater. Process. Tech. 283, 116690 (2020)

H. Talebi-Ghadikolaee, H.M. Naeini, M.J. Mirnia, M.A. Mirzai, S. Alexandrov, H. Gorji, Int. J. Adv. Manuf. Tech. 105, 5217 (2019)

Y.B. Bao, Ph.D. Thesis, Massachusetts Institute of Technology (2003)

H. Li, M.W. Fu, J. Lu, H. Yang, Int. J. Plasticity 27, 147 (2011)

C.C. Roth, D. Mohr, Int. J. Plasticity 56, 19 (2014)

M. Dunand, D. Mohr, Eng. Fract. Mech. 78, 2919 (2011)

F. Ozturk, D. Lee, J. Mater. Process. Tech. 147, 397 (2004)

H. Takuda, K. Mori, N. Takakura, K. Yamaguchi, Int. J. Mech. Sci. 42, 785 (2000)

C. Cheng, B. Meng, J.Q. Han, M. Wan, X.D. Wu, R. Zhao, Mater. Design 118, 89 (2017)

L.R. Sun, Z.Y. Cai, D.Y. He, L. Li, Metals 9, 1129 (2019)

Acknowledgements

The authors would like to acknowledge the financial support provided by the National Natural Science Foundation of China (Grant No. 51975248).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, L., Cai, Z., Gao, J. et al. Calibration of Ductile Fracture Criterion with Optimal Experiment Design and Prediction on Forming Limit for Aluminum Alloy Sheet. Met. Mater. Int. 28, 848–861 (2022). https://doi.org/10.1007/s12540-021-00970-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00970-3