Abstract

GFRP pipes are increasingly used all around the globe mainly because of its high corrosive resistance and light weight properties. GFRP are employed in the industries involving chemical processes, such as, water treatment, desalination and in petrochemical industries for handling oil & gas at offshore platforms. The studies on the reliability of the GFRP pipes and its defect occurring probabilities are widely performed, in which, pitting or wall loss defect is one of the severe defects which may produce in service stage and lead to leakage accidents. This paper explores the potential of lock-in results to quantification of pitting or wall loss defects in unidirectional filament wound GFRP curved composite materials. This work is focusing on quantification of defect depth through thermal diffusion and amplitude contrast methods. For defect sizing Full Width at Half Maximum method (FWHM) has been used. A detailed systematic investigation on defect depth and size quantification at various depths of the unidirectional GFRP curved sample is studied with the amplitude and phase images.

Similar content being viewed by others

References

ArabiHassen, A., Vaidya, U.K., Britt, F.: Structural integrity of fibre reinforced plastic piping. Mater. Eval. 73, 918–929 (2015)

Ainsworth, L.: Fibre Reinforced plastics pipes and applications. Composites 12, 185–190 (1981). https://doi.org/10.1016/0010-4361(81)90501-2

Wright, M.: Ultrasonic nondestructive evaluation of GRP pipes—Sure2GriP—quality assurance and structural evaluation of GRP pipes horizontal research activities involving SME. In: European conference on NDT 2006, Berlin, Germany, pp 1–10 (2006)

Montanini, R., Freni, F.: Non-destructive evaluation of thick glass fiber-reinforced composites by means of optically excited lock-in thermography. Compos. A 43, 2075–2082 (2012). https://doi.org/10.1016/j.compositesa.2012.06.004

Gashoot, S.R., Al-Madani, R.A.: A survey of GRP pipes defects and damage due to fabrication processes. In: International Conference on Production and Mechanical Engineering (ICPME’2014), 30–31 December 2014, Bangkok, Thailand (2014)

Shen, G., Li, T.: Infrared thermography test for high temperature pressure pipe. Insight 49, 151–153 (2007). https://doi.org/10.1784/insi.2007.49.3.151

Dong, J., Kim, B., Locquet, A., McKeon, P., Declercq, N., Citrin, D.S.: Nondestructive evaluation of forced delamination in glass fiber-reinforced composites by terahertz and ultrasonic waves. Composites B Eng. 79, 667–675 (2015). https://doi.org/10.1016/j.compositesb.2015.05.028

Gholizadeh, S.: A review of non-destructive testing methods of composite materials. Procedia Struct. Integrity 1, 50–57 (2016). https://doi.org/10.1016/j.prostr.2016.02.008

Scott, I.G., Scala, C.M.: A review of non-destructive testing of composite materials. NDT Int. 15, 75–86 (1982). https://doi.org/10.1016/0308-9126(82)90001-3

Sharath, D., Menaka, M., Venkatraman, B.: Defect characterization using pulsed and lock-in thermography: a comparative study. J. Non-destruct. Test. Eval. 32, 134–141 (2012)

Vijayaraghavan, G.K., Sundaravalli, S.: Evaluation of pits in GRP composite pipes by thermal NDT technique. J. Reinfor. Plastics Compos 30, 1599–1604 (2011). https://doi.org/10.1177/0731684411423119

Busse, G.: Optoacoustic phase angle measurement for probing a metal. Appl. Phys. Lett. 35, 759–760 (1978). https://doi.org/10.1063/1.90960

Montanini, R.: Quantitative determination of subsurface defects in a reference specimen made of Plexiglas by means of lock-in and pulse phase infrared thermography. Infrared Phys. Technol. 53, 363–371 (2010). https://doi.org/10.1016/j.infrared.2010.07.002

Menaka, M., Sharath, D., Venkatraman, B., Raj, B.: Precise depth detection of EDM notches by lock-in thermography. J. Non-destruct. Test. Eval. 8, 15–18 (2009)

Choia, M., Kanga, K., Parka, J., Kimb, W., Kimc, K.: Quantitative determination of a subsurface defect of reference specimen by lock-in infrared thermography. NDT&E Int. 41, 119–124 (2008). https://doi.org/10.1016/j.ndteint.2007.08.006

Sharath, A., Menaka, M., Venkatraman, B., Raj, B.: Defect depth quantification using lockin thermography. Quant. Infrared Thermogr. J. 12, 37–52 (2015). https://doi.org/10.1080/17686733.2015.1013663

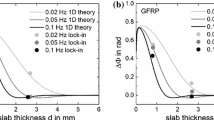

Ranjit, S., Choi, M., Kim, W.: Quantification of defects depth in glass fiber reinforced plastic plate by infrared lock-in thermography. J. Mech. Sci. Technol. 30, 1111–1118 (2016). https://doi.org/10.1007/s12206-016-0215-5

Sakagami, T., Kubo, S.: Applications of pulse heating thermography and lock-in thermography to quantitative nondestructive evaluations. Infrared Phys. Technol. 43, 211–218 (2002). https://doi.org/10.1016/S1350-4495(02)00141-X

Saintey, M.B., Almond, D.P.: Defect sizing by transient thermography. II. A numerical treatment. J. Phys. D Appl. Phys 28, 2539–2546 (1995). https://doi.org/10.1088/0022-3727/28/12/023

Vavilov, V.P., Pawar, S.: Determining the lateral size of subsurface defects during active thermal nondestructive testing. Russ J Nondestruct Test 52, 528–531 (2016). https://doi.org/10.1134/S1061830916090084

Meola, C., Carlomagno, G.M., Squillace, A., Giorleo, G.: Non-destructive control of industrial materials by means of lock-in thermography. Meas. Sci. Technol. 13, 1583–1590 (2002). https://doi.org/10.1088/0957-0233/13/10/311

Wui, D., Rantala, J., Karpeni, W., Zenzinger, G., SchOnbach, B., Rippeli, W., Steegmiilleri, R., Dieneri, L., Busse, G.: Applications of lockin-thermography methods. Rev. Prog. Quant. Nondestruct. Eval. 15, 511–518 (1996). https://doi.org/10.1007/978-1-4613-0383-1_65

Wallbrink, C., Wade, S.A., Jones, R.: The effect of size on the quantitative estimation of defect depth in steel structures using lock-in thermography. J. Appl. Phys. 101, 104907 (2007). https://doi.org/10.1063/1.2732443

Meola, C., Carlomagno, G.M.: Impact damage in GFRP: new insights with infrared thermography. Compos. A Appl. Sci. Manuf. 41, 1839–1847 (2010). https://doi.org/10.1016/j.compositesa.2010.09.002

Palumbo, D., Tamborrino, R., Galietti, U., Aversa, P., Tatì, A., Luprano, V.A.M.: Ultrasonic analysis and lock-in thermography for debonding evaluation of composite adhesive joints. NDT&E Int. 78, 1–9 (2016). https://doi.org/10.1016/j.ndteint.2015.09.001

Vijayaragavan, G.K., Majumder, M., Ramachandran, K.P.: NDTE using flash thermography: numerical modelling and analysis of delaminations in GRP pipes. Insight 52, 481–487 (2010)

Palumbo, D.: On the thickness quantification of composite materials by using lock-in thermography. Materials 12(7), 1185 (2019). https://doi.org/10.3390/ma12071185

Junyan, L., Liqiang, L., Yang, W.: Experimental study on active infrared thermography as a NDI tool for carbon–carbon composites. Composites Part B Eng. (2013). https://doi.org/10.1016/j.compositesb.2012.09.006

Krapez, J.C.: Compared performances of four algorithms used for modulation thermography. In: Quantitative Infrared Thermography—QIRT’98, Łódź, Poland. https://doi.org/10.21611/qirt.1998.023.

Acknowledgements

The authors thank Director, Indira Gandhi centre for Atomic Research, Kalpakkam for permitting to use the lock-in thermographic facility. This research received no specific scholarship from any funding agency.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gomathi, R., Ashok, M., Menaka, M. et al. Quantification of Wall Loss Defect in Glass Fiber Reinforced Polymer Curved Composites Using Lock-In Thermography. J Nondestruct Eval 40, 42 (2021). https://doi.org/10.1007/s10921-021-00774-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-021-00774-w