Abstract—

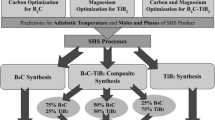

Based on analysis of phase diagram data and thermodynamic modeling, we have evaluated the optimal temperature ranges of the processes underlying the preparation of B4C–TiB2 and B4C–ZrB2 composite powders via boron carbide reactions in the presence of excess boron carbide: 2MO2 + (n + 1)B4C + 3C = 2MB2 + 4CO + nB4C (M = Ti, Zr). The values of n have been taken so as to obtain composite powders with the following compositions (mol %): 90B4C–10MB2 (n = 19), 80B4C–20MB2 (n = 9), 75B4C–25MB2 (n = 7), and 70B4C–30MB2 (n = 5.67). We have found temperatures that ensure the preparation of composite powders with tailored composition at various CO pressures. At a CO pressure of 0.0773 MPa, these temperatures for both reactions are 1816 K (~1540°C), independent of the composition of the synthesized powders. The eutectic temperature in the B4C–TiB2 system is ~2200°C and that in the B4C–ZrB2 system is ~2280°C. Thus, at a nearly atmospheric pressure in the reactor, the optimal synthesis temperature of B4C–TiB2 composite powder lies in the range 1540–2200°C and that of B4C–ZrB2 composite powder lies in the range 1540–2280°C. Such powders are potentially attractive for the fabrication of ceramics with improved performance parameters.

Similar content being viewed by others

REFERENCES

Spohn, M.T., Annual minerals review. Boron carbide, Am. Ceram. Soc. Bull., 1995, vol. 74, no. 6, pp. 113–115.

Kislyi, P.S., Kuzenkova, M.A., Bodnaruk, N.I., and Grabchuk, B.L., Karbid bora (Boron Carbide), Kiev: Naukova Dumka, 1988.

Serebryakova, T.I., Neronov, V.A., and Peshev, P.D., Vysokotemperaturnye boridy (High-Temperature Borides), Moscow: Metallurgiya, 1991.

Zhang, W., Yamashita, S., and Kita, H., Progress in pressureless sintering of boron carbide ceramics – a review, Adv. Appl. Ceram., 2019, vol. 118, no. 4, pp. 222–239. https://doi.org/10.1080/17436753.2019.1574285

Heydari, M.S. and Baharvandi, H.R., Effect of different additives on the sintering ability and the properties of B4C–TiB2 composites, Int. J. Refract. Met. Hard Mater., 2015, vol. 51, pp. 61–69. https://doi.org/10.1016/j.ijrmhm.2015.02.014

Ordan’yan, S.S., Stepanenko, K.K., Dmitriev, A.I., and Shchemeleva, M.V., interaction in the B4C–TiB2 system, Sverkhtverd. Mater., 1986, no. 5, pp. 27–29.

Huang, S., Vanmeensel, K., Malek, O., van der Biest, O., and Vleugels, J., Microstructure and mechanical properties of pulsed electric current sintered B4C–TiB2 composites, Mater. Sci. Eng., A, 2011, vol. 528, no. 3, pp. 1302–1309. https://doi.org/10.1016/j.msea.2010.10.022

Xu, C., Cai, Y., Flodström, K., Li, Z., Esmaeilzadeh, S., and Zhang, G.-J., Spark plasma sintering of B4C ceramics: the effects of milling medium and TiB2 addition, Int. J. Refract. Met. Hard Mater., 2012, vol. 30, no. 1, pp. 139–144. https://doi.org/10.1016/j.ijrmhm.2011.07.016

Ordan’yan, S.S., Dmitriev, A.I., Bizhev, K.T., and Stepanenko, E.K., Interaction in the B4C–ZrB2 system, Poroshk. Metall., 1988, no. 1, pp. 41–43.

Mestvirishvili, Z., Bairamashvili, I., Kvatchadze, V., and Rekhviashvili, N., Thermal and mechanical properties of B4C–ZrB2 ceramic composite, J. Mater. Sci. Eng., B, 2015, vols. 9–10, pp. 385–393. https://doi.org/10.17265/2161-6221/2015.9-10.007

Chakraborty, S., Debnath, D., Mallick, A.R., and Das, P.K., Mechanical, tribological, and thermal properties of hot-pressed ZrB2–B4C composite, Int. J. Appl. Ceram. Technol., 2014, vol. 9, pp. 1–9. https://doi.org/10.1111/ijac.12290

Dudina, D.V., Hulbert, D.M., Jiang, D., Unuvar, C., Cytron, S.J., and Mukherjee, A.K., In situ boron carbide–titanium diboride composites prepared by mechanical milling and subsequent spark plasma sintering, J. Mater. Sci., 2008, vol. 43, no. 10, pp. 3569–3576. https://doi.org/10.1007/s10853-008-2563-8

Nikzad, L., Licheri, R., Ebadzadeh, T., Orru, R., and Cao, G., Effect of ball milling on reactive spark plasma sintering of B4C–TiB2 composites, Ceram. Int., 2012, vol. 38, no. 8, pp. 6469–6480. https://doi.org/10.1016/j.ceramint.2012.05.024

Hulbert, D., Jiang, M.D., Dudina, D.V., and Mukherjee, A.K., The synthesis and consolidation of hard materials by spark plasma sintering, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, no. 2, pp. 367–375. https://doi.org/10.1016/j.ijrmhm.2008.09.011

Shcherbakov, V.A., Gryadunov, A.N., and Alymov, A.I., Synthesis and characteristics of the B4C–ZrB2 composites, Lett. Mater., 2017, vol. 7, no. 4, pp. 398–401. https://doi.org/10.22226/2410-3535-2017-4-398-401

Guo, W.-M., Wu, L.-X., You, Y., Lin, H.-T., and Zhang, G.-J., Three-step reactive hot pressing of B4C–ZrB2 ceramics, J. Eur. Ceram. Soc., 2016, vol. 36, no. 4, pp. 951–957. https://doi.org/10.1016/j.jeurceramsoc.2015.11.022

Huang, S., Vanmeensel, K., van der Biest, O., and Vleugels, J., In situ synthesis and densification of submicrometer-grained B4C–TiB2 composites by pulsed electric current sintering, J. Eur. Ceram. Soc., 2011, vol. 31, no. 4, pp. 637–644. https://doi.org/10.1016/j.jeurceramsoc.2010.10.028

Skorokhod, V. and Krstic, V., High strength-high toughness B4C–TiB2 composites, J. Mater. Sci. Lett., 2000, vol. 19, pp. 237–239. https://doi.org/10.1023/A:1006766910536

Wang, Y.-J., Peng, H.-X., Ye, F., and Zhou, Y., Effect of TiB2 content on microstructure and mechanical properties of in-situ fabricated TiB2/B4C composites, Trans. Nonferrous Met. Soc. China, 2011, vol. 21, no. 2, pp. 369–373. https://doi.org/10.1016/S1003-6326(11)61608-7

Svoistva elementov. Spravochnoe izdanie (Properties of Elements: A Handbook), Samsonov, G.V., Ed., Moscow: Metallurgiya, 1976, part 1.

Bolgar, A.S., Turchanin, A.G., and Fesenko, V.V., Termodinamicheskie svoistva karbidov (Thermodynamic Properties of Carbides), Kiev: Naukova Dumka, 1973.

Fiziko-khimicheskie svoistva okislov. Spravochnoe izdanie (Physicochemical Properties of Oxides: A handbook), Samsonov, G.V., Ed., Moscow: Metallurgiya, 1978.

West, A.R., Solid State Chemistry and Its Applications, Chichester: Wiley, 1985, part 1.

Kuznetsov, F.A. and Smirnova, T.P., Fundamental’nye osnovy protsessov khimicheskogo osazhdeniya plenok i struktur dlya nanoelektroniki (Fundamental Principles behind the Growth of Films and Structures for Nanoelectronics by Chemical Deposition), Novosibirsk: Sib. Otd. Ross. Akad. Nauk, 2013.

Sulyaeva, V.S., Shestakov, V.A., Rumyantsev, Yu.M., and Kosinova, M.L., Synthesis of zirconium diboride films and ZrB2/BCxNy heterostructures, Inorg. Mater., 2018, vol. 54, no. 2, pp. 133–139. https://doi.org/10.1134/S0020168518020152

Shestakov, V.A., Kosyakov, V.I., and Kosinova, M.L., Chemical vapor deposition of boron-containing films using B(OAlk)3 as precursors: thermodynamic modeling, Russ. Chem. Bull., 2019, no. 11, pp. 1983–1990.

Kiseleva, N.N., Komp’yuternoe konstruirovanie neorganicheskikh soedinenii. Ispol’zovanie baz dannykh i metodov iskusstvennogo intellekta (Computer Design of Inorganic Compounds: Use of Databases and Artificial Intelligence Methods), Moscow: Nauka, 2005.

Gurvich, L.V., Veits, I.V., Medvedev, V.A., Khachkuruzov, G.A., Yungman, V.S., Bergman, G.A., Baibuz, V.F., Iorish, V.S., Yurkov, G.N., Gorbov, S.I., Nazarenko, I.I., Dorofeeva, O.V., Kuratova, L.F., Osina, E.L., Gusarov, A.V., Leonidov, V.Ya., Przheval’skii, I.N., Rogatskii, A.L., Efremov, Yu.M., Ryabova, V.G., Zitserman, V.Yu., Khait, Yu.G., Shenyavskaya, E.A., Efimov, M.E., Kulemza, V.A., Khodeev, Yu.S., Tomberg, S.E., Vdovin, V.N., Yakobson, A.Ya., and Demidova, M.S., Termodinamicheskie svoistva individual’nykh veshchestv: Spravochnoe izdanie (Thermodynamic Properties of Pure Substances: A Handbook), Moscow: Nauka, 1982, vol. 4, issue 1.

Funding

This work was supported through the Development of Novosibirsk State Technical University Program, research project no. S20-19.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Shestakov, V.A., Gudyma, T.S., Krutskii, Y.L. et al. Evaluation of the Temperature Range Suitable for the Synthesis of B4C–TiB2 and B4C–ZrB2 Powder Composite Materials. Inorg Mater 57, 481–486 (2021). https://doi.org/10.1134/S0020168521050083

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521050083