Abstract

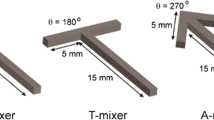

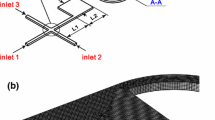

In the present study, a joint experimental and numerical study on mass transfer inside vortex-based micro-capillary channels by virtue of chaotic mixing theory is presented. Three different microfluidic chips with different embedded barrier shapes, including cubic, angled cubic, and cylindrical barriers with the same blockage ratio posed behind a couple of symmetric semi-cylinder barriers as mixing promoters inside the channel were designed. To find the optimum geometrical parameters, Optimal Design (OD) method was employed. The results showed that different patterns of vortices can be achieved when the shape of embedded barriers change. The mass transfer or disturbance posed by vortices which were made by streamlines on the local position based on cavity was not only dependent on its vorticity, but also correlates with the fluid stretching based on the Lyapunov exponent theory. Consequently, the application and recognition of suitable vortex patterns play important parts in mixing enhancement. Additionally, three different micromixers with three different embedded barrier shapes produced different vortices sizes at different Re numbers ranging from 0.05 to 93, leading to different mixing performances. The micromixer with middle cubic barriers showed a better mixing trends due to the higher vortex size and lateral fluid velocity. Both experimental findings and numerical results showed that more asymmetric shapes lead to better fluid mixing. It was observed that when the semi-cylinder obstacle radius is greater than 180 µm, large vortices are formed after the obstacles act as hydrodynamic barriers, which in turn promote the cavity-based trapped vortex and fluid stretching.

Similar content being viewed by others

References

Afzal A, Kim K-Y (2012) Passive split and recombination micromixer with convergent–divergent walls. Chem Eng J 203:182–192

Afzal A, Kim K-Y (2015) Optimization of pulsatile flow and geometry of a convergent–divergent micromixer. Chem Eng J 281:134–143

Alizadeh A, De Castro CN, Wakeham W (1980) The theory of the taylor dispersion technique for liquid diffusivity measurements. Int J Thermophys 1:243–284

Amiri Z, Movahedirad S (2017) Bubble-induced particle mixing in a 2-D gas-solid fluidized bed with different bed aspect ratios: a CFD-DPM study. Powder Technol 320:637–645. https://doi.org/10.1016/j.powtec.2017.07.097

Aref H (1984) Stirring by chaotic advection. J Fluid Mech 143:1–21

Bae HJ, Lozano-Duran A, Bose S, Moin P (2018) Turbulence intensities in large-eddy simulation of wall-bounded flows. Phys Rev Fluids 3:014610

Berger PD, Maurer RE, Celli GB (2018) Introduction to response-surface methodology. In: Experimental design. Springer, pp 533–584

Borgohain P, Arumughan J, Dalal A, Natarajan G (2018a) Design and performance of a three-dimensional micromixer with curved ribs. Chem Eng Res Des 136:761–775. https://doi.org/10.1016/j.cherd.2018.06.027

Borgohain P, Dalal A, Natarajan G, Gadgil H (2018b) Numerical assessment of mixing performances in cross-T microchannel with curved ribs. Microsyst Technol 24:1949–1963

Chen X, Li T (2017) A novel passive micromixer designed by applying an optimization algorithm to the zigzag microchannel. Chem Eng J 313:1406–1414

Chen X, Shen J (2017) Numerical analysis of mixing behaviors of two types of E-shape micromixers. Int J Heat Mass Transf 106:593–600

Chen X, Wang X (2015) Optimized modular design and experiment for staggered herringbone chaotic micromixer. Int J Chem React Eng 13:305–309

Chen CH et al (2010) Antimicrobial susceptibility testing using high surface-to-volume ratio microchannels. Anal Chem 82:1012–1019

Chen X, Li T, Li X (2016a) Numerical research on shape optimization of microchannels of passive micromixers. IEEE Sens J 16:6527–6532

Chen X, Li T, Zeng H, Hu Z, Fu B (2016b) Numerical and experimental investigation on micromixers with serpentine microchannels. Int J Heat Mass Transf 98:131–140

Chen S, Zhang T, Lv L, Chen Y, Yang Y, Tang S (2019) Intensification of the liquid side mass transfer in double-side falling film microchannels by micro-mixing structures. Chem Eng Sci 193:264–275

Cullen PJ, Romañach RJ, Abatzoglou N, Rielly CD (2015) Pharmaceutical blending and mixing. Wiley

Daneyko A, Hlushkou D, Baranau V, Khirevich S, Seidel-Morgenstern A, Tallarek U (2015) Computational investigation of longitudinal diffusion, eddy dispersion, and trans-particle mass transfer in bulk, random packings of core–shell particles with varied shell thickness and shell diffusion coefficient. J Chromatogr A 1407:139–156

Duryodhan VS, Chatterjee R, Govind Singh S, Agrawal A (2017) Mixing in planar spiral microchannel. Exp Thermal Fluid Sci 89:119–127. https://doi.org/10.1016/j.expthermflusci.2017.07.024

Fan L-L, Zhu X-L, Zhao H, Zhe J, Zhao L (2017) Rapid microfluidic mixer utilizing sharp corner structures. Microfluid Nanofluid 21:36

Haghighinia A, Movahedirad S (2019a) Fluid micro-mixing in a passive microchannel: comparison of 2D and 3D numerical simulations. Int J Heat Mass Transf 139:907–916. https://doi.org/10.1016/j.ijheatmasstransfer.2019.05.084

Haghighinia A, Movahedirad S (2019b) Mass transfer in a novel passive micro-mixer: flow tortuosity effects. Anal Chim Acta. https://doi.org/10.1016/j.aca.2019.11.028

Haghighinia A, Movahedirad S, Rezaei AK, Mostoufi N (2020) On-chip mixing of liquids with high-performance embedded barrier structure. Int J Heat Mass Transf 158:119967

Hermann P, Timmermann J, Hoffmann M, Schlüter M, Hofmann C, Löb P, Ziegenbalg D (2018) Optimization of a split and recombine micromixer by improved exploitation of secondary flows. Chem Eng J 334:1996–2003. https://doi.org/10.1016/j.cej.2017.11.131

Hsiao K-Y, Wu C-Y, Huang Y-T (2014) Fluid mixing in a microchannel with longitudinal vortex generators. Chem Eng J 235:27–36. https://doi.org/10.1016/j.cej.2013.09.010

Islami SB, Khezerloo M, Gharraei R (2017) The effect of chaotic advection on mixing degree and pressure drop of non-Newtonian fluids flow in curved micromixers. J Braz Soc Mech Sci Eng 39:813–831

Jen C-P, Wu C-Y, Lin Y-C, Wu C-Y (2003) Design and simulation of the micromixer with chaotic advection in twisted microchannels. Lab Chip 3:77–81

Kashid M, Renken A, Kiwi-Minsker L (2011) Mixing efficiency and energy consumption for five generic microchannel designs. Chem Eng J 167:436–443. https://doi.org/10.1016/j.cej.2010.09.078

Khuri AI, Mukhopadhyay S (2010) Response surface methodology. Wiley Interdiscip Rev Comput Stat 2:128–149

Leith SD, King DA, Paul B (2010) Toward low-cost fabrication of microchannel process technologies-cost modeling for manufacturing development. Pacific Northwest National Lab.(PNNL), Richland, WA (United States

Liauw MA, Baerns M, Broucek R, Buyevskaya OV, Commenge JM, Corriou JP, Steinfeldt N (2000) Periodic operation in microchannel reactors. In: Microreaction Technology: Industrial Prospects. Springer, Berlin, Heidelberg, pp 224–234

Majdi H, Esfahani J, Mohebbi M (2019) Optimization of convective drying by response surface methodology. Comput Electron Agric 156:574–584

Manning JR (1961) Diffusion in a chemical concentration gradient. Phys Rev 124:470

Mariotti A, Galletti C, Mauri R, Salvetti MV, Brunazzi E (2018) Steady and unsteady regimes in a T-shaped micro-mixer: synergic experimental and numerical investigation. Chem Eng J 341:414–431

Mengeaud V, Josserand J, Girault HH (2002) Mixing processes in a zigzag microchannel: finite element simulations and optical study. Anal Chem 74:4279–4286

Movahedirad S, Ghafari M, Molaei Dehkordi A (2014) A novel model for predicting the dense phase behavior of 3D gas-solid fluidized beds. Chem Eng Technol 37:103–112. https://doi.org/10.1002/ceat.201300432

Mu Q, Li Y, Zhang Q, Wang H (2011) TiO2 nanofibers fixed in a microfluidic device for rapid determination of chemical oxygen demand via photoelectrocatalysis. Sens Actuators B Chem 155:804–809

Navarro R, Zinchenko A, Davis R (2019) Manipulating drop shapes in a microchannel. In: APS March Meeting Abstracts, vol 2019, pp V48-006

Nosrati K, Movahedirad S, Sobati MA, Sarbanha AA (2017) Experimental study on the pressure wave attenuation across gas-solid fluidized bed by single bubble injection. Powder Technol 305:620–624. https://doi.org/10.1016/j.powtec.2016.10.051

Orsi G, Roudgar M, Brunazzi E, Galletti C, Mauri R (2013) Water–ethanol mixing in T-shaped microdevices. Chem Eng Sci 95:174–183. https://doi.org/10.1016/j.ces.2013.03.015

Rahimi M, Aghel B, Hatamifar B, Akbari M, Alsairafi A (2014) CFD modeling of mixing intensification assisted with ultrasound wave in a T-type microreactor. Chem Eng Process 86:36–46

Raza W, Hossain S, Kim K-Y (2018) Effective mixing in a short serpentine split-and-recombination micromixer. Sens Actuators B Chem 258:381–392. https://doi.org/10.1016/j.snb.2017.11.135

Su Y, Chen G, Yuan Q (2011) Ideal micromixing performance in packed microchannels. Chem Eng Sci 66:2912–2919. https://doi.org/10.1016/j.ces.2011.03.024

Tang G, Li X, He Y, Tao W (2009) Electroosmotic flow of non-Newtonian fluid in microchannels. J Nonnewton Fluid Mech 157:133–137

Usefian A, Bayareh M (2020) Numerical and experimental investigation of an efficient convergent–divergent micromixer. Meccanica 55(5):1025–1035

Ward K, Fan ZH (2015) Mixing in microfluidic devices and enhancement methods. J Micromech Microeng 25:094001

Yang J-T, Huang K-J, Lin Y-C (2005) Geometric effects on fluid mixing in passive grooved micromixers. Lab Chip 5:1140–1147

Funding

This work did not receive any specific grants from funding agencies in the public, commercial, or non-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Haghighinia, A., Movahedirad, S. Experimental investigation and CFD simulation of cavity flow effects on liquids mixing in vortex-based microfluidic chips: Quantitative visualization and optimization by response surface method (RSM). Braz. J. Chem. Eng. 38, 297–313 (2021). https://doi.org/10.1007/s43153-021-00109-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-021-00109-2