Abstract

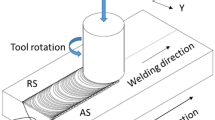

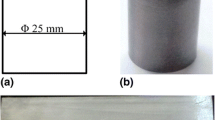

The microstructure and corrosion behavior of friction stir (FS) welded API X-60 pipeline steel were investigated. Three FS welds were successfully fabricated under various welding conditions using a tungsten carbide-base tool. It was found that the microstructure and corrosion performance of the welds were strongly affected by welding parameters. A thermal history study of the welds showed that all stir zones heated up to the temperature of the ferrite–austenite region. Electron backscatter diffraction (EBSD) characterizations revealed that a significant grain refinement in the stir zones was accompanied by the formation of low angle grain boundaries. The kernel average misorientation analyses showed that the amount of residual strain and dislocation density were increased after welding. The corrosion assessments using potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) measurements showed that the welds exhibited superior corrosion resistance than that of the base metal. There results were confirmed according to the immersion tests.

Similar content being viewed by others

References

Sampath K, J Mater Eng Perform 15 (2006) 32.

Davis J R, ASM Internatinal 17 (2001) 193.

Sha W, Springer (2013).

Show B K, Veerababu R, Balamuralikrishnan R, Malakondaiah G, Mater Sci Eng A 527 (2010) 1595.

Hong S, Kang K, Park C, Scripta Materialia 46 (2002) 163.

Sun W, Wang G, Zhang J, Xia D, Sun H, J Mater Sci Technol 25 (2009) 857.

Yayla P, Kaluc E, Ural K, Mater Des 28 (2007) 1898.

Kang J, Wang C, Wang G, Mater Sci Eng A 553 (2012) 96.

Konkol P, Warren J, Welding Journal 77 (1998) 361.

Caron J, Babu S, Lippold J, Welding Journal 92 (2013) 110.

Mishra R S, Kumar N, Springer (2014).

Kumar K, Kalyan C, Mater Manuf Proces 24 (2009) 438.

Lienert T, Stellwag W, Welding Journal 82 (2003) 1.

Pradeep A, Inter J of Eng Research Develop 3 (2012) 75.

McPherson N, Galloway A, Cater S, Hambling S, Sci Technol of Weld Join 18 (2013) 441.

Barnes S, Bhatti A, Steuwer A, Johnson R, Altenkirch J, Withers P, Metall and Maters Trans A 43 (2012) 2342.

Sunilkumar D, Muthukumaran S, Trans Indian Inst Met 72 (2019) 1537.

Baker T N, McPherson N A, J Mater Sci Techn 32 (2016) 234.

Mironov S, Sato Y, Kokawa H, Acta Materialia 56 (2008) 2606.

Konkol P J, Mruczek M F, Welding Journal 86 (2007) 187.

Ozekcin A, Jin H, Inter J of Offshore and Polar Eng 14 (2004) 284.

Ragu Nathan S, Balasubramanian V, Trans Indian Inst Met 69 (2016) 1861.

Ghosh M, Kumar K, Mishra R, Mater Sci Eng A 528 (2011) 8111.

Nelson T W, Rose S A, J Mater Process Technol 231 (2016) 66.

Wei L, Nelson T W, Mater Sci Eng A 556 (2012) 51.

Nathan S R, Balasubramanian V, Malarvizhi S, Rao A, Defense Technol 11 (2015) 307.

Ramesh R, Dinaharan I, Kumar R, Akinlabi E, Mater Sci Eng A 687 (2017) 39.

Abbasi M, Nelson T W, Mater Character 66 (2012) 1.

Bhadeshia H, Honeycombe R, Butterworth-Heinemann (2011).

Wang Z, Li P, Guan Y, Chen Q, Pu S, Corr Sci 51 (2009) 954.

Chen Y, Tzeng H, Wei L, Wang L, Oung J, Shih H, Corr Sci 47 (2005) 1001.

Guo J, Yang S, Shang C, Wang Y, He X, Corr Sci 51 (2009) 242.

Moon A, Sangal S, Layek S, Giribaskar S, Mondal K, Metall and Maters Transs A 46 (2015) 1500.

Kumar V, Chaudhuri S K, Corr Reviews 21 (2003) 293.

Lakshmana R B, Chaudhari P, Nath S, Mater and Des 32 (2011) 433.

Abbaszadeh K, Saghafian H, J Mater Sci Tech 28 (2012) 236.

Trinh D, Frappart S, Ruckert G, Cortial F, Touzain S, Corr Eng Sci Technol 54 (2019) 353.

Rajesh S, Vishvesh B, Mater and Manufact Process 33 (2018) 156.

Sarlak H, Atapour M, Esmailzadeh M, Mater and Des 66 (2015) 209.

Navaser M, Atapour M, J Mater Sci Techno 33 (2017) 155.

Atapour M, Pilchak A L, Frankel G S, Williams J C, Metall Mater Trans A 41 (2010) 2318.

Seikh A, Sherif E, Int J. Electrochem. Sci 10 (2015) 895.

Guo Y, Li C, Liu Y, Yu L, Int J Min, Met Mater 22 (2015) 604.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Behjat, A., Shamanian, M., Atapour, M. et al. Microstructure and Corrosion Properties of Friction Stir-Welded High-Strength Low -Alloy Steel. Trans Indian Inst Met 74, 1763–1774 (2021). https://doi.org/10.1007/s12666-021-02219-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02219-4