Abstract

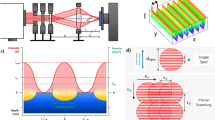

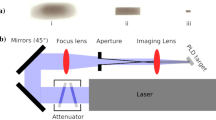

Irradiation of yttria-stabilized zirconia (YSZ) was performed by a femtosecond pulsed laser to investigate the feasibility of V-shaped groove microstructure fabrication. Firstly, fundamental characteristics of microgroove fabrication was investigated by varying scanning speed of laser and number of scans. Higher scanning speed resulted in a smooth surface without any debris adhesion. By increasing number of scans, the cross-sectional profile of the microgroove became a well-defined V shape, and the taper angle of the V-shaped groove can be precisely controlled by laser scanning speed. Moreover, the laser-induced phase transformation of YSZ was characterized, and it was found that the monoclinic ratio after irradiation decreased in comparison with original YSZ surface, indicating improved strength and toughness. TEM cross-sectional observation of the microgrooves was performed and tetragonal phase was detected independent of locations. Finally, micro pyramid structures were created on the YSZ surface by perpendicularly crossing the laser scan directions. The resulting surface showed a drastic change in surface wettability. These findings demonstrated the possibility of generating precise complex microstructures on YSZ surface with high functionality and low subsurface damage, presenting great potential of wide applications in industry.

Similar content being viewed by others

References

Garvie, R. C., Hannink, R. H., & Pascoe, R. T. (1975). Ceramic steel? Nature, 258(5537), 703–704. https://doi.org/10.1038/258703a0

Scott, H. G. (1975). Phase relationships in the zirconia–yttria system. Journal of Materials Science, 10(9), 1527–1535. https://doi.org/10.1007/BF01031853

Gupta, T. K., Lange, F. F., & Bechtold, J. H. (1978). Effect of stress-induced phase transformation on the properties of polycrystalline zirconia containing metastable tetragonal phase. Journal of Materials Science, 13(7), 1464–1470. https://doi.org/10.1007/BF00553200

Piconi, C., & Maccauro, G. (1999). Zirconia as a ceramic biomaterial. Biomaterials, 20(1), 1–25. https://doi.org/10.1016/S0142-9612(98)00010-6

Sailer, I., Philipp, A., Zembic, A., Pjetursson, B. E., Hämmerle, C. H. F., & Zwahlen, M. (2009). A systematic review of the performance of ceramic and metal implant abutments supporting fixed implant reconstructions. Clinical Oral Implants Research, 20(SUPPL. 4), 4–31. https://doi.org/10.1111/j.1600-0501.2009.01787.x

Cho, G. Y., Yu, W., Lee, Y. H., Lee, Y., Tanveer, W. H., Kim, Y., Lee, S., Cha, S. W. (2020). Effects of nanoscale PEALD YSZ interlayer for AAO based thin film solid oxide fuel cells. International Journal of Precision Engineering and Manufacturing Green Technology, 7(2), 423–430. https://doi.org/10.1007/s40684-019-00082-9

Stanciuc, A. M., Flamant, Q., Sprecher, C. M., Alini, M., Anglada, M., & Peroglio, M. (2018). Femtosecond laser multi-patterning of zirconia for screening of cell-surface interactions. Journal of the European Ceramic Society, 38(3), 939–948. https://doi.org/10.1016/j.jeurceramsoc.2017.08.019

Carvalho, A., Cangueiro, L., Oliveira, V., Vilar, R., Fernandes, M. H., & Monteiro, F. J. (2018). Femtosecond laser microstructured alumina toughened zirconia: A new strategy to improve osteogenic differentiation of hMSCs. Applied Surface Science, 435, 1237–1245. https://doi.org/10.1016/j.apsusc.2017.11.206

Carvalho, A., Grenho, L., Fernandes, M. H., Daskalova, A., Trifonov, A., Buchvarov, I., & Monteiro, F. J. (2020). Femtosecond laser microstructuring of alumina toughened zirconia for surface functionalization of dental implants. Ceramics International, 46(2), 1383–1389. https://doi.org/10.1016/j.ceramint.2019.09.101

Ji, M., Xu, J., Chen, M., & El Mansori, M. (2020). Enhanced hydrophilicity and tribological behavior of dental zirconia ceramics based on picosecond laser surface texturing. Ceramics International, 46(6), 7161–7169. https://doi.org/10.1016/j.ceramint.2019.11.210

Chen, F., Zhang, D., Yang, Q., Yong, J., Du, G., Si, J., Yun, F., Hou, X. (2013). Bioinspired wetting surface via laser microfabrication. ACS Applied Materials and Interfaces, 5(15), 6777–6792. https://doi.org/10.1021/am401677z

Yao, L., & He, J. (2014). Recent progress in antireflection and self-cleaning technology—From surface engineering to functional surfaces. Progress in Materials Science, 61, 94–143. https://doi.org/10.1016/j.pmatsci.2013.12.003

Yan, J., & Okuuchi, T. (2019). Chip morphology and surface integrity in ultraprecision cutting of yttria-stabilized tetragonal zirconia polycrystal. CIRP Annals, 68(1), 53–56. https://doi.org/10.1016/j.cirp.2019.04.050

Holthaus, M. G., Twardy, S., Stolle, J., Riemer, O., Treccani, L., Brinksmeier, E., & Rezwan, K. (2012). Micromachining of ceramic surfaces: Hydroxyapatite and zirconia. Journal of Materials Processing Technology, 212(3), 614–624. https://doi.org/10.1016/j.jmatprotec.2011.06.007

Lu, A., Gao, Y., Jin, T., Luo, X., Zeng, Q., & Shang, Z. (2020). Effects of surface roughness and texture on the bacterial adhesion on the bearing surface of bio-ceramic joint implants: An in vitro study. Ceramics International, 46(5), 6550–6559. https://doi.org/10.1016/j.ceramint.2019.11.139

Smielak, B., & Klimek, L. (2015). Effect of hydrofluoric acid concentration and etching duration on select surface roughness parameters for zirconia. Journal of Prosthetic Dentistry, 113(6), 596–602. https://doi.org/10.1016/j.prosdent.2015.01.001

Takayama, N., Asaka, S., & Yan, J. (2018). Nanosecond pulsed laser irradiation of sapphire for developing microstructures with deep V-shaped grooves. Precision Engineering, 52(February), 440–450. https://doi.org/10.1016/j.precisioneng.2018.02.008

Aguilar-Morales, A. I., Alamri, S., & Lasagni, A. F. (2018). Micro-fabrication of high aspect ratio periodic structures on stainless steel by picosecond direct laser interference patterning. Journal of Materials Processing Technology, 252, 313–321. https://doi.org/10.1016/j.jmatprotec.2017.09.039

Fiedler, S., Irsig, R., Tiggesbäumker, J., Schuster, C., Merschjann, C., Rothe, N., Lochbrunner, S., Vehse, M., Seitz, H., Klinkenberg, E.-D., Meiwes-Broer, K.-H. (2013). Machining of biocompatible ceramics with femtosecond laser pulses. Biomedical Engineering Biomedizinische Technik, 58, 3–4. https://doi.org/10.1515/bmt-2013-4093

Kim, M., Lee, S. M., Lee, S. J., Kim, Y. W., Liang-Li, & Lee, D. W. (2017). Effect on friction reduction of micro/nano hierarchical patterns on sapphire wafers. International Journal of Precision Engineering and Manufacturing Green Technology, 4(1), 27–35. https://doi.org/10.1007/s40684-017-0004-3

Wang, X. C., Wu, L. Y. L., Shao, Q., & Zheng, H. Y. (2009). Laser micro structuring on a Si substrate for improving surface hydrophobicity. Journal of Micromechanics and Microengineering, 19(8), 085025. https://doi.org/10.1088/0960-1317/19/8/085025

Chevalier, J., Gremillard, L., Virkar, A. V., & Clarke, D. R. (2009). The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. Journal of the American Ceramic Society, 92(9), 1901–1920. https://doi.org/10.1111/j.1551-2916.2009.03278.x

Grigore, A., Spallek, S., Petschelt, A., Butz, B., Spiecker, E., & Lohbauer, U. (2013). Microstructure of veneered zirconia after surface treatments: A TEM study. Dental Materials, 29(11), 1098–1107. https://doi.org/10.1016/j.dental.2013.07.022

Feng, D., & Shen, H. (2019). Hole quality control in underwater drilling of yttria-stabilized zirconia using a picosecond laser. Optics and Laser Technology, 113, 141–149. https://doi.org/10.1016/j.optlastec.2018.12.019

Li, J., Ji, L., Hu, Y., & Bao, Y. (2016). Precise micromachining of yttria-tetragonal zirconia polycrystal ceramic using 532 nm nanosecond laser. Ceramics International, 42(3), 4377–4385. https://doi.org/10.1016/j.ceramint.2015.11.118

Roitero, E., Anglada, M., Mücklich, F., & Jiménez-Piqué, E. (2018). Mechanical reliability of dental grade zirconia after laser patterning. Journal of the Mechanical Behavior of Biomedical Materials, 86(June), 257–263. https://doi.org/10.1016/j.jmbbm.2018.06.039

Cai, Y., Chang, W., Luo, X., & Qin, Y. (2019). Superhydrophobicity of microstructured surfaces on zirconia by nanosecond pulsed laser. Journal of Micromanufacturing, 2(1), 5–14. https://doi.org/10.1177/2516598418799933

Roitero, E., Lasserre, F., Roa, J. J., Anglada, M., Mücklich, F., & Jiménez-Piqué, E. (2017). Nanosecond-laser patterning of 3Y-TZP: Damage and microstructural changes. Journal of the European Ceramic Society, 37(15), 4876–4887. https://doi.org/10.1016/j.jeurceramsoc.2017.05.052

Delgado-Ruíz, R. A., Calvo-Guirado, J. L., Moreno, P., Guardia, J., Gomez-Moreno, G., Mate-Sánchez, J. E., Ramirez-Fernández, P., Chiva, F. (2011). Femtosecond laser microstructuring of zirconia dental implants. Journal of Biomedical Materials Research Part B Applied Biomaterials, 96 B(1), 91–100. https://doi.org/10.1002/jbm.b.31743

Ackerl, N., & Wegener, K. (2019). Ablation characteristics of alumina and zirconia ceramics on ultra-short pulsed laser machining. Journal of Laser Micro Nanoengineering, 14(2), 168–172. https://doi.org/10.2961/jlmn.2019.02.0009

Bonse, J., Hohm, S., Kirner, S. V., Rosenfeld, A., & Kruger, J. (2017). Laser-induced periodic surface structures—A scientific evergreen. IEEE Journal of Selected Topics in Quantum Electronics, 23(3), 109–123. https://doi.org/10.1109/JSTQE.2016.2614183

Jing, X., Pu, Z., Zheng, S., Wang, F., & Qi, H. (2020). Nanosecond laser induced microstructure features and effects thereof on the wettability in zirconia. Ceramics International, 46(15), 24173–24182. https://doi.org/10.1016/j.ceramint.2020.06.197

Milewski, J., & Sklar, E. (1996). Modelling and validation of multiple reflections for enhanced laser welding. Modelling and Simulation in Materials Science and Engineering, 4(3), 305–322. https://doi.org/10.1088/0965-0393/4/3/005

Samant, A. N., & Dahotre, N. B. (2009). Laser machining of structural ceramics—A review. Journal of the European Ceramic Society, 29(6), 969–993. https://doi.org/10.1016/j.jeurceramsoc.2008.11.010

Muñoz Tabares, J. A., & Anglada, M. J. (2010). Quantitative analysis of monoclinic phase in 3Y-TZP by Raman spectroscopy. Journal of the American Ceramic Society, 93(6), 1790–1795. https://doi.org/10.1111/j.1551-2916.2010.03635.x

Kosmač, T., Oblak, Č, & Marion, L. (2008). The effects of dental grinding and sandblasting on ageing and fatigue behavior of dental zirconia (Y-TZP) ceramics. Journal of the European Ceramic Society, 28(5), 1085–1090. https://doi.org/10.1016/j.jeurceramsoc.2007.09.013

Roitero, E., Ochoa, M., Anglada, M., Mücklich, F., & Jiménez-Piqué, E. (2018). Low temperature degradation of laser patterned 3Y-TZP: Enhancement of resistance after thermal treatment. Journal of the European Ceramic Society, 38(4), 1742–1749. https://doi.org/10.1016/j.jeurceramsoc.2017.10.044

Yamamuro, Y., Shimoyama, T., Yamashita, I., & Yan, J. (2020). Multiscale surface patterning of zirconia by picosecond pulsed laser irradiation. Journal of Micro and Nano-Manufacturing, 8(1), 8–13. https://doi.org/10.1115/1.4046040

Raghavan, S., Wang, H., Dinwiddie, R. B., Porter, W. D., & Mayo, M. J. (1998). The effect of grain size, porosity and yttria content on the thermal conductivity of nanocrystalline zirconia. Scripta Materialia, 39(8), 1119–1125. https://doi.org/10.1016/S1359-6462(98)00290-5

Wenzel, R. N. (1936). Resistance of solid surfaces to wetting by water. Industrial and Engineering Chemistry, 28(8), 988–994. https://doi.org/10.1021/ie50320a024

Cassie, A. B. D., & Baxter, S. (1944). Wettability of porous surfaces. Transactions of the Faraday Society, 40, 546–551. https://doi.org/10.1039/tf9444000546

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yamamuro, Y., Shimoyama, T. & Yan, J. Microscale Surface Patterning of Zirconia by Femtosecond Pulsed Laser Irradiation. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 619–632 (2022). https://doi.org/10.1007/s40684-021-00362-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00362-3