Abstract

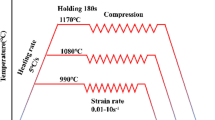

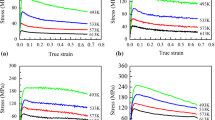

The thermal compression tests of Ti-22Al-26Nb-2Ta alloy under T = 1173 ~ 1423 K and \(\dot{\varepsilon }\) = 0.001 ~ 10 s−1 were carried out on the Gleeble-3500 thermo-mechanical simulator. The flow stress curves were obtained, and the high-temperature rheological properties of the alloy were analyzed. The 3D activation energy maps were calculated and constructed. The least squares support vector machine (LSSVM) model of constitutive relation was established, and the penalty coefficient and kernel parameter of the LSSVM model were optimized by genetic algorithm (GA). The constitutive model of the alloy based on the GA-LSSVM algorithm was constructed. The predicted value of the model was also compared with the experimental data. The dynamic material model (DMM) and polar reciprocity model (PRM) were used to establish the 3D processing map of the alloy and appropriate thermal processing parameters. Our researches indicated that deformation temperature and strain rate have a great influence on the flow stress of Ti-22Al-26Nb-2Ta alloy. Ti-22Al-26Nb-2Ta alloy is a negative temperature-sensitive and a positive strain rate-sensitive material. The correlation coefficient of GA-LSSVM algorithm constitutive model is 0.9922, and the relative error of most samples is within 10%, accounting for 93.18%. The model has high prediction accuracy and strong generalization ability. The DMM processing map based on the Prasad instability criterion is more accurate in optimizing the processing parameters of the alloy than that of the PRM processing map through analyzing the 3D processing map and observing the microstructure. The instability modes in the instability region of the alloy mainly include adiabatic shear, crack, and local flow. The 1173 ~ 1273 K/0.001 ~ 0.003 s−1 are the best parameters during the processing of the alloy.

Graphic Abstract

Similar content being viewed by others

References

D. Banerjee, A.K. Gogia, T.K. Nandi, V. Joshi, Acta Metall. 36, 871 (1988)

S. Li, Y. Mao, J. Zhang, J. Li, Y. Cheng, Z. Zhong, T. Nonferr. Metal. Soc. 4, 582 (2002)

M.R. Shagiev, R.M. Galeyev, O.R. Valiakhmetov, R.V. Safiullin, Adv. Mater. Res. 59, 105 (2009)

S. Ren, K. Wang, S. Lu, Y. Huang, Q. Xu, X. Gao, Rare Metal Mat. Eng. 47, 2793 (2018)

K. Tan, J. Li, Z. Guan, J. Yang, J. Shu, Mater. Design 84, 204 (2015)

F.C. Ren, J. Chen, F. Chen, Appl. Mech. Mater. 552, 247 (2014)

P.L. Narayana, C.-L. Li, J.-K. Hong, S.-W. Choi, C. H. Park, S.-W. Kim, S. E. Kim, N.S. Reddy, J.-T. Yeom, Met. Mater. Int. 25, 1063 (2019)

L. Yang, H. Su, F. Chai, X. Luo, L. Duan, Mater. China 38, 672 (2019)

Z. Zhou, J. Morel, D. Parsons, S.V. Kucheryavskiy, A.-M. Gustavsson, Comput. Electron. Agr. 162, 246 (2019)

Z. Yao, J. Dong, M. Zhang, L. Zheng, Q. Yu, Rare Metal Mat. Eng. 42, 1199 (2013)

Z. Shi, X. Yan, C. Duan, J. Alloy. Compd. 652, 30 (2015)

C. Zhang, L. Zhang, W. Shen, C. Liu, Y. Xia, R. Li, Mater. Design 90, 804 (2016)

N.Q. Chinh, G. Racz, J. Gubicza. R.Z. Valiev, T.G. Langdon, Mater. Sci. Eng. A 759, 448 (2019)

K. Sofinowski, M. Šmíd, I. Kuběna, S. Vivès, N. Casati, S. Godet, H. Van Swygenhoven, Acta Mater. 179, 224 (2019)

J.K. Hwang, Met. Mater. Int. 26, 603 (2020)

C.M. Li, Y. Liu, Y.B. Tan, F. Zhao, Metals 8, 846 (2018)

R.R. Xu, H. Li, M.Q. Li, Mater. Design 186, 108328 (2020)

M.A. Wahed, A.K. Gupta, V. Sharma, K. Mahesh, S. K. Singh, N. Kotkunde, Int. J. Adv. Manuf. Tech. 104, 3419 (2019)

J.J. Jonas, C.M. Sellars, W.J.M. Tegart, Metall. Rev. 14, 1 (1969)

Y.C. Lin, M.S. Chen, J. Zhong, Comput. Mater. Sci. 42, 470 (2008)

P.M. Sargent, M.F. Ashby, Scripta Metall. 16, 1415 (1982)

Y. Sun, Z. Wan, L. Hu, J. Ren, Mater. Design 86, 922 (2015)

L. Li, M.Q. Li, Mater. Sci. Eng. A 698, 302 (2017)

H. Gwon, S. Shin, J. Jeon, T. Song, S. Kim, B.C. De Cooman, Met. Mater. Int. 25, 594 (2019)

Y.P. Gu, W.J. Zhao, Z.S. Wu, J. Tsinghua Univ. (Sci. Technol.) 50, 1063 (2010)

A.O. Mosleh, A.V. Mikhaylovskaya, A.D. Kotov, J.S. Kwame, S.A. Aksenov, Materials 12, 1756 (2019)

A. Mosleh, A. Mikhaylovskaya, A. Kotov, T. Pourcelot, S. Aksenov, J. Kwame, V. Portnoy, Metals 7, 568 (2017)

A.O. Mosleh, A.D. Kotov, P. Mestre-Rinn, A.V.Mikhaylovskaya, Procedia Manuf. 37, 239 (2019)

A.O. Mosleh, P. Mestre-Rinn, A.M. Khalil, A.D. Kotov, A.V. Mikhaylovskaya, Mater. Res. Express 7, 016504 (2020)

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15, 1883 (1984)

X.M. Yang, H.Z. Guo, Z.K. Yao, S.C. Yuan, S.W. Xin, Rare Metals 37, 778 (2018)

A. Łukaszek-Sołek, J. Krawczyk, T. Śleboda, J. Grelowski, J. Mater Res. Technol. 8, 3281 (2019)

Y.V.R.K. Prasad, J. Mater. Eng. Perform. 12, 638 (2003)

Y.V.R.K. Prasad, Indian J. Technol. 28, 435 (1990)

S.B. Bhimavarapu, A.K. Maheshwari, D. Bhargava, S.P. Narayan, J. Mater. Sci. 46, 3191 (2011)

T. Rajagopalachary, V.V. Kutumbarao, Scripta Mater. 35, 311 (1996)

V.V. Kutumbarao, T. Rajagopalachary, B. Mater. Sci. 19, 677 (1996)

S.V.S.N. Murty, B.N. Rao, Mater. Sci. Eng. A 254, 76 (1998)

Q.Y. Yu, Z.H. Yao, J.X. Dong, P.D. Zhang, G. Han, Trans. Mater. Heat Treat. 36(7), 30 (2015)

C. Ma, G.C. Wang, Forg. Stamp. Technol. 41, 88 (2016)

Y.S. Wang, R.K. Linghu, Y.Y. Liu, J.X. Hu, J. Xu, J.W. Qiao, X.M. Wang, J. Alloy. Compd. 751, 391 (2018)

L. Tan, Y. Li, F. Liu, Y. Nie, L. Jiang, J. Mater. Sci. Technol. 35, 2591 (2019)

Acknowledgements

The study was supported by the Key Project of Natural Science Foundation of Jiangxi Province (No. 20202ACBL204001) and the National Natural Science Foundation of China (No. 51464035). The authors thank AiMi Academic Services (www.aimieditor.com) for English language editing and review services.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, P., Zou, H., Wang, K. et al. Hot Deformation Behaviors of Ti-22Al-26Nb-2Ta Alloy Based on GA-LSSVM and 3D Processing Map. Met. Mater. Int. 27, 4235–4249 (2021). https://doi.org/10.1007/s12540-021-01016-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01016-4