Abstract

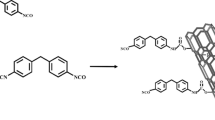

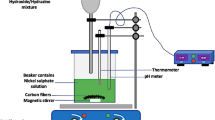

Conducting fibers with improved properties and functionalities are needed for diverse applications. Here we report the fabrication of core/shell conductive Dacron fibers by dip-coating method through originating from multi-walled carbon nanotubes (MWCNTs) coated on polyester fibers. The annealing process was conducted to enhance interaction between the conductive shell and polyester core as well as within the MWCNTs network. The properties of two kinds of MWCNTs dispersions and the electrical properties of conductive fibers were studied, respectively. The results show that both MWCNTs-polyurethane resin (MWCNTs-WPU) dispersion and MWCNTs-acrylic resin (MWCNTs-PAA) dispersion present a typical characteristic of pseudo-plastic fluid and an excellent wetting ability to polyester fibers. The ultimate tensile stress and elongation at break for the MWCNTs-PAA coated fiber are 261 MPa and 25.43%. The ultimate tensile stress and the elongation at break are both increasing with the increasing of MWCNTs contents, due to the strong interface bonding ability between the conductive shell and polyester core and strengthen the MWCNTs network. The electrical resistance of the obtained fibers can be controlled in the range from 732 to 30 Ω/cm by changing MWCNTs content, dipping times and annealing temperature. It was found that it is able to light a LED. All results suggest that the conductive fibers embody a good synergy effect of carbon nanotubes and polymers. Therefore, the fabricated conductive fibers have a widely prospect for being applied in the field of flexible electronics.

Similar content being viewed by others

References

Cao Z, Wang R, He T, Xu F, Sun J. Interface-controlled conductive fibers for wearable strain sensors and stretchable conducting wires. ACS Appl Mater Interfaces. 2018;10:14087–96.

Xiang C, Lu W, Zhu Y, Sun Z, Yan Z, Hwang CC, Tour JM. Carbon nanotube and graphene nanoribbon-coated conductive Kevlar fibers. ACS Appl Mater Interfaces. 2012;4:131–6.

Wang Z, Huang Y, Sun J, Huang Y, Hu H, Jiang R, Gai W, Li G, Zhi C. Polyurethane/cotton/carbon nanotubes core-spun yarn as high reliability stretchable strain sensor for human motion detection. ACS Appl Mater Interfaces. 2016;8:24837–43.

Ryu S, Lee P, Chou JB, Xu R, Zhao R, Hart AJ, Kim SG. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano. 2015;9:5929–36.

Arbab AA, Sun KC, Sahito IA, Qadir MB, Jeong SH. Multiwalled carbon nanotube coated polyester fabric as textile based flexible counter electrode for dye sensitized solar cell. Phys Chem Chem Phys. 2015;17:12957–69.

Lee J, Kwon H, Seo J, Shin S, Koo JH, Pang C, Son S, Kim JH, Jang YH, Kim DE, Lee T. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv Mater. 2015;27:2433–9.

Cheng Y, Wang R, Sun J, Gao L. Highly conductive and ultra-stretchable electric circuits from covered yarns and silver nanowires. ACS Nano. 2015;9:3887–95.

Won Y, Kim A, Yang W, Jeong S, Moon J. A highly stretchable, helical copper nanowire conductor exhibiting a stretchability of 700%. Npg Asia Mater. 2014;6:e132.

Qu G, Cheng J, Li X, Yuan D, Chen P, Chen X, Wang B, Peng H. A fiber supercapacitor with high energy density based on hollow graphene/conducting polymer fiber electrode. Adv Mater. 2016;28:3646–52.

Liu K, Sun Y, Lin X, Zhou R, Wang J, Fan S, Jiang K. Scratch-resistant, highly conductive, and high-strength carbon nanotube-based composite yarns. ACS Nano. 2010;4:5827–34.

Foroughi J, Spinks GM, Wallace GG, Oh J, Kozlov ME, Fang S, Mirfakhrai T, Madden JD, Shin MK, Kim SJ. Torsional carbon nanotube artificial muscles. Science. 2011;334:494–7.

Lv T, Yao Y, Li N, Chen T. Wearable fiber-shaped energy conversion and storage devices based on aligned carbon nanotubes. Nano Today. 2016;11:644–60.

Zeng W, Shu L, Li Q, Chen S, Wang F, Tao XM. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Adv Mater. 2014;26:5310–6.

Zu M, Li Q, Wang G, Byun JH, Chou TW. Carbon nanotube fiber based stretchable conductor. Adv Funct Mater. 2013;23:789–93.

Liu Y, Kumar S. Polymer/carbon nanotube nano composite fibers—a review. ACS Appl Mater Interfaces. 2014;6:6069–87.

Li YL, Kinloch IA, Windle AH. Direct spinning of carbon nanotube fibers from chemical vapor deposition synthesis. Science. 2004;304:276–8.

Mukai K, Asaka K, Wu X, Morimoto T, Okazaki T, Saito T, Yumura M. Wet spinning of continuous polymer-free carbon-nanotube fibers with high electrical conductivity and strength. Appl Phys Express. 2016;9:1–3.

Park G, Jung Y, Lee G-W, Hinestroza JP, Jeong Y. Carbon nanotube/poly(vinyl alcohol) fibers with a sheath-core structure prepared by wet spinning. Fiber Polym. 2012;13:874–9.

Zhao L, Li Y, Liu Z, Shimizu H. Carbon nanotube-conducting polymer core−shell hybrid using an imidazolium-salt-based ionic liquid as a linker: designed as a potential platinum electrode alternative material for large-scale solution processing. Chem Mater. 2010;22:5949–56.

Fugetsu B, Akiba E, Hachiya M, Endo M. The production of soft, durable, and electrically conductive polyester multifilament yarns by dye-printing them with carbon nanotubes. Carbon. 2009;47:527–30.

Kowalczyk D, Brzeziński S, Makowski T, Fortuniak W. Conductive hydrophobic hybrid textiles modified with carbon nanotubes. Appl Surf Sci. 2015;357:1007–14.

Shim BS, Chen W, Doty C, Xu C, Kotov NA. Smart electronic yarns and wearable fabrics for human biomonitoring made by carbon nanotube coating with polyelectrolytes. Nano Lett. 2008;8:4151–7.

Gholami H, Arab H, Mokhtarifar M, Maghrebi M, Baniadam M. The effect of choline-based ionic liquid on CNTs’ arrangement in epoxy resin matrix. Mater Des. 2016;91:180–5.

Liu X, Nie Y, Meng X, Zhang Z, Zhang X, Zhang S. DBN-based ionic liquids with high capability for the dissolution of wool keratin. Rsc Adv. 2017;7:1981–8.

Hu YF, Wang B, Zhang XN, Zhang J, Zhu J. Development of multiwalled-carbon-nanotube-welded carbon fibers and evaluation of the interfacial strength in epoxy composites. J Appl Polym Sci. 2017;134:45027–33.

Wu ML, Chen Y, Zhang L, Zhan H, Qiang L, Wang JN. High performance carbon nanotube/polymer composite fiber from layer-by-layer deposition. ACS Appl Mater Interfaces. 2016;8:8137–44.

Le HH, Wießner S, Das A, Fischer D, Landwehr MAD, Do QK, Stöckelhuber KW, Heinrich G, Radusch HJ. Selective wetting of carbon nanotubes in rubber compounds—effect of the ionic liquid as dispersing and coupling agent. Eur Polym J. 2016;75:13–24.

Mandal A, Nandi AK. Ionic liquid integrated multiwalled carbon nanotube in a poly(vinylidene fluoride) matrix: formation of a piezoelectric β-polymorph with significant reinforcement and conductivity improvement. ACS Appl Mater Interfaces. 2013;5:747–60.

Janas D, Kreft SK, Koziol KKK. Printing of highly conductive carbon nanotubes fibres from aqueous dispersion. Mater Des. 2016;116:16–20.

Jiang S, Zhang H, Song S, Ma Y, Li J, Lee GH, Han Q, Liu J. Highly stretchable conductive fibers from few-walled carbon nanotubes coated on poly(m-phenylene isophthalamide) polymer core/shell structures. ACS Nano. 2015;9:10252–7.

Zheng Q, Xue Q, Yan K, Hao L, Qun Li A, Gao X. Investigation of molecular interactions between SWNT and polyethylene/polypropylene/polystyrene/polyaniline molecules. J Phys Chem C. 2007;111:4628–35.

Liu W, Yang CL, Yingtao Zhu A, Wang M. Interactions between single-walled carbon nanotubes and polyethylene/polypropylene/polystyrene/poly(phenylacetylene)/poly(p-phenylenevinylene) considering repeat unit arrangements and conformations: a molecular dynamics simulation study. J Phys Chem C. 2008;112:1803–11.

Ku-Herrera JJ, Avilés F, Nistal A, Cauich-Rodríguez JV, Rubio F, Rubio J, Bartolo-Pérez P. Interactions between the glass fiber coating and oxidized carbon nanotubes. Appl Surf Sci. 2015;330:383–92.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 21776276, and 21978306), Zhengzhou High Level Talent (20180300045), “Recruitment of Outstanding Technologist” of Chinese Academy of Sciences; State Key Laboratory of Multiphase Complex Systems, IPE, CAS (No. MPCS-2015-A-05).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Ma, L., Nie, Y., Liu, Y. et al. Preparation of Core/Shell Electrically Conductive Fibers by Efficient Coating Carbon Nanotubes on Polyester. Adv. Fiber Mater. 3, 180–191 (2021). https://doi.org/10.1007/s42765-021-00082-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-021-00082-y