Abstract

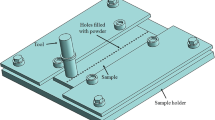

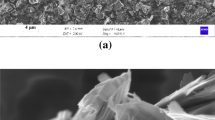

In the present work, 2024-T351 Al alloy reinforced with alumina particulates (Al2O3p) was elaborated using friction stir processing (FSP). The effect of solution heat treatment followed by subsequent aging on microstructure, hardness, and tribological behavior is discussed. It was noticed that the hardness of the as-FSPed 2024-T351/Al2O3p was slightly enhanced in comparison to the as-received AA2024-T351 material, whereas the resulting wear resistance was remarkably improved. After heat treatment process, the composite volume increased, and swelling and pores were created at the processed area. The heat treatment caused a degradation in wear resistance compared to as-FSPed composites. The precipitation mechanism changed for AA2024/Al2O3p; reactions occurred at grain boundaries between Al2O3 and Cu or Mg, causing their depletion from the Al matrix. Intriguingly, the precipitation mode in heat-affected zone of the matrix also changed to grain boundary precipitation.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Kok M (2005) Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J Mater Process Technol 161:381–387. https://doi.org/10.1016/j.jmatprotec.2004.07.068

Kök M, Özdin K (2007) Wear resistance of aluminium alloy and its composites reinforced by Al2O3 particles. J Mater Process Technol 183:301–309. https://doi.org/10.1016/j.jmatprotec.2006.10.021

Ünlü BS (2008) Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater Des 29:2002–2008. https://doi.org/10.1016/j.matdes.2008.04.014

Abdel-Azim AN, Shash Y, Mostafa SF, Younan A (1995) Casting of 2024-Al alloy reinforced with Al2O3 particles. J Mater Process Technol 55:199–205. https://doi.org/10.1016/0924-0136(95)01954-5

Sajjadi SA, Ezatpour HR, Beygi H (2011) Microstructure and mechanical properties of Al-Al2O3 micro and nano composites fabricated by stir casting. Mater Sci Eng A 528:8765–8771. https://doi.org/10.1016/j.msea.2011.08.052

Xu H, Zhang G, Cui W, Ren SB, Wang QJ, Qu XH (2018) Effect of Al2O3sf addition on the friction and wear properties of (SiCp+Al2O3sf)/Al2024 composites fabricated by pressure infiltration. Int J Miner Metall Mater 25:375–382. https://doi.org/10.1007/s12613-018-1581-z

Daoud A, Abou El-Khair MT, Abdel-Azim AN (2004) Effect of Al2O3 particles on the microstructure and sliding wear of 7075 Al alloy manufactured by squeeze casting method. J Mater Eng Perform 13:135–143. https://doi.org/10.1361/10599490418325

Lloyd DJ (1994) Particle reinforced aluminium and magnesium matrix composites. Int Mater Rev 39:1–23. https://doi.org/10.1179/imr.1994.39.1.1

Forn A, Teresa Baile M, Rupérez E (2003) Spinel effect on the mechanical properties of metal matrix composite AA6061/(Al2O3)p. J Mater Process Technol 143–144:58–61. https://doi.org/10.1016/S0924-0136(03)00319-4

El-Mahallawi I, Ahmed MMZ, Mahdy AA et al (2017) Effect of heat treatment on friction-stir-processed nanodispersed AA7075 and 2024 Al alloys BT - friction stir welding and processing IX. In: Hovanski Y, Mishra R, Sato Y et al (eds) . Springer International Publishing, Cham, pp 297–309

Schultz BF, Ferguson JB, Rohatgi PK (2011) Microstructure and hardness of Al2O3 nanoparticle reinforced Al-Mg composites fabricated by reactive wetting and stir mixing. Mater Sci Eng A 530:87–97. https://doi.org/10.1016/j.msea.2011.09.042

Wang N, Wang Z, Weatherly GC (1992) Formation of magnesium aluminate (spinel) in cast SiC particulate-reinforced Al(A356) metal matrix composites. Metall Trans A 23:1423–1430. https://doi.org/10.1007/BF02647325

Vani VV, Chak SK (2018) The effect of process parameters in aluminum metal matrix composites with powder metallurgy. Manuf Rev 5. https://doi.org/10.1051/mfreview/2018001

Sharma V, Prakash U, Kumar BVM (2015) Surface composites by friction stir processing: a review. J Mater Process Technol 224:117–134. https://doi.org/10.1016/j.jmatprotec.2015.04.019

Rathee S, Maheshwari S, Siddiquee AN (2018) Issues and strategies in composite fabrication via friction stir processing: a review. Mater Manuf Process 33:239–261. https://doi.org/10.1080/10426914.2017.1303162

Hoziefa W, Toschi S, Ahmed MMZ, Morri A, Mahdy AA, el-Sayed Seleman MM, el-Mahallawi I, Ceschini L, Atlam A (2016) Influence of friction stir processing on the microstructure and mechanical properties of a compocast AA2024-Al2O3 nanocomposite. Mater Des 106:273–284. https://doi.org/10.1016/j.matdes.2016.05.114

Moustafa E (2017) Effect of multi-pass friction stir processing on mechanical properties for AA2024/Al2O3 nanocomposites. Materials 2017, 10, 1053. https://doi.org/10.3390/ma10091053

Bharti S, Ghetiya ND, Patel KM (2020) Micro-hardness and wear behavior of AA2014/Al2O3 surface composite produced by friction stir processing. SN Appl Sci 2:1760. https://doi.org/10.1007/s42452-020-03585-2

Ghanbari D, Kasiri Asgarani M, Amini K, Gharavi F (2017) Influence of heat treatment on mechanical properties and microstructure of the Al2024/SiC composite produced by multi–pass friction stir processing. Measurement 104:151–158. https://doi.org/10.1016/j.measurement.2017.03.024

Geng J, Hong T, Ma Y, Wang M, Chen D, Ma N, Wang H (2016) The solution treatment of in-situ sub-micron TiB2/2024 Al composite. Mater Des 98:186–193. https://doi.org/10.1016/j.matdes.2016.03.024

Refat M, Abdelmotagaly AMM, Ahmed MMZ, El-Mahallawi I (2016) The effect of heat treatment on the properties of friction stir processed AA7075-O with and without nano alumina additions BT - friction stir welding and processing VIII. In: Mishra RS, Mahoney MW, Sato Y, Hovanski Y (eds) . Springer International Publishing, Cham, pp 115–123

Zhang J, Alpas AT (1997) Transition between mild and severe wear in aluminium alloys. Acta Mater 45:513–528. https://doi.org/10.1016/S1359-6454(96)00191-7

Zhang J, Alpas AT (1993) Wear regimes and transitions in Al2O3 particulate-reinforced aluminum alloys. Mater Sci Eng A 161:273–284. https://doi.org/10.1016/0921-5093(93)90522-G

Hannard F, Castin S, Maire E, Mokso R, Pardoen T, Simar A (2017) Ductilization of aluminium alloy 6056 by friction stir processing. Acta Mater 130:121–136. https://doi.org/10.1016/j.actamat.2017.01.047

Ghanbari D, Asgarani MK, Amini K, Gharavi F (2017) Influence of heat treatment on mechanical properties and microstructure of. Measurement. 104:151–158. https://doi.org/10.1016/j.measurement.2017.03.024

Jang J-H, Nam D-G, Park Y-H, Park I-M (2013) Effect of solution treatment and artificial aging on microstructure and mechanical properties of Al–Cu alloy. Trans Nonferrous Metals Soc China 23:631–635. https://doi.org/10.1016/S1003-6326(13)62509-1

Yang K, Li W, Niu P, Yang X, Xu Y (2018) Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: microstructure characterization, mechanical performance and strengthening mechanisms. J Alloys Compd 736:115–123. https://doi.org/10.1016/j.jallcom.2017.11.132

Tekmen C, Cocen U (2003) The effect of Si and Mg on age hardening behavior of Al-SiCp composites. J Compos Mater 37:1791–1800. https://doi.org/10.1177/002199803035181

Mitchell CA, Davidson AM (2000) Effect of Al2O3 particulates as reinforcement in age hardenable aluminium alloy composites. Mater Sci Technol 16:873–876. https://doi.org/10.1179/026708300101508595

Cöcen Ü, Önel K, Özdemir I (1997) Microstructures and age hardenability of AL-5%si-0.2%Mg based composites reinforced with particulate SiC. Compos Sci Technol 57:801–808. https://doi.org/10.1016/S0266-3538(97)00049-3

Li W, Liao NM, Jiang YD, Shen BL (2007) Interface study of short mullite fibre reinforced Al–Cu–Mg alloy composites. Mater Sci Technol 23:229–232. https://doi.org/10.1179/174328407X157254

Das T, Munroe PR, Bandyopadhyay S (1996) The effect of Al2O3 particulates on the precipitation behaviour of 6061 aluminium-matrix composites. J Mater Sci 31:5351–5361. https://doi.org/10.1007/BF01159304

Briant CL (2001) Grain boundary structure, chemistry, and failure. Mater Sci Technol 17:1317–1323. https://doi.org/10.1179/026708301101509331

Li BQ, Reynolds AP (1998) Correlation of grain-boundary precipitates parameters with fracture toughness in an Al–Cu–Mg–Ag alloy subjected to long-term thermal exposure. J Mater Sci 33:5849–5853. https://doi.org/10.1023/A:1004426820624

Steele D, Evans D, Nolan P, Lloyd DJ (2007) Quantification of grain boundary precipitation and the influence of quench rate in 6XXX aluminum alloys. Mater Charact 58:40–45. https://doi.org/10.1016/j.matchar.2006.03.007

Tatar C, Özdemir N (2010) Investigation of thermal conductivity and microstructure of the α-Al2O3 particulate reinforced aluminum composites (Al/Al2O3-MMC) by powder metallurgy method. Phys B Condens Matter 405:896–899. https://doi.org/10.1016/j.physb.2009.10.010

Jiang S, Wang R (2019) Grain size-dependent Mg/Si ratio effect on the microstructure and mechanical/electrical properties of Al-Mg-Si-Sc alloys. J Mater Sci Technol 35:1354–1363. https://doi.org/10.1016/j.jmst.2019.03.011

Prabhu TR (2017) Effects of ageing time on the mechanical and conductivity properties for various round bar diameters of AA 2219 Al alloy. Eng Sci Technol Int J 20:133–142. https://doi.org/10.1016/j.jestch.2016.06.003

Azimzadegan T, Serajzadeh S (2010) An investigation into microstructures and mechanical properties of AA7075-T6 during friction stir welding at relatively high rotational speeds. J Mater Eng Perform 19:1256–1263. https://doi.org/10.1007/s11665-010-9625-1

Liu Y, Deng C, Gong B, Bai Y (2019) Effects of heterogeneity and coarse secondary phases on mechanical properties of 7050-T7451 aluminum alloy friction stir welding joint. Mater Sci Eng A 764:138223. https://doi.org/10.1016/j.msea.2019.138223

Alpas AT, Zhang J (1992) Effect of SiC particulate reinforcement on the dry sliding wear of aluminium-silicon alloys (A356). Wear 155:83–104. https://doi.org/10.1016/0043-1648(92)90111-K

Chiker N, Benamor A, Hadji Y, Haddad A, Hakem M, Azzaz M, Sahraoui T, Hadji M (2020) Microstructure and tribological behavior of in situ TiC-Ni(Si,Ti) composites elaborated from Ni and Ti3SiC2 powders. J Mater Eng Perform 29:1995–2005. https://doi.org/10.1007/s11665-020-04710-3

Acknowledgements

The authors would like thank Air Algérie company for providing the Al alloy 2024-T351 sheets. Special thanks to Miss Selma Hanifi and Mr. Walid Bedjaoui of Research Center in Industrial Technologies (CRTI) for their help during SEM and XRD characterization. This work was supported by Direction Générale de la Recherche Scientifique et du Développement Technologique (DGRSDT), Algeria.

Funding

This work was supported by the Algerian general directory of scientific research and technological development (DGRSDT), Algeria.

Author information

Authors and Affiliations

Contributions

Adel Haddad and Abdessabour Benamor were responsible for the experimental work, Nabil Chiker and Youcef Hadji carried out the XRD analysis, Maamar Hakem and Riad Badji were responsible of the SEM analysis, Said Abdi assured tribological testing, and Mustapha Temmar and Mohamed Hadji contributed to making the final draft of the paper. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haddad, A., Benamor, A., Chiker, N. et al. Effect of heat treatment on microstructure and tribological behavior of friction stir processed Al2O3-reinforced AA2024-T351 matrix. Int J Adv Manuf Technol 115, 1671–1681 (2021). https://doi.org/10.1007/s00170-021-07237-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07237-6