Abstract

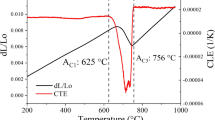

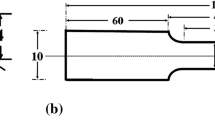

Nickel-free high-manganese austenitic Fe–24.4Mn–4.04Al–0.057C steel was produced by smelting, and the homogenized forged billet was hot-rolled. The plastic deformation mechanism was investigated through tensile testing of the hot-rolled sample. Different characterization techniques such as scanning electron microscopy, transmission electron microscopy, electron backscattered diffraction, and X-ray diffraction were used to analyze the microstructural evolution of steel under different strain levels. The steel had a single austenite phase, which was stable during deformation. After hot rolling, annealing twins were observed in the microstructure of the steel. The steel showed an excellent combination of mechanical properties, like a tensile strength of 527 MPa, impact energy of 203 J at − 196 °C, and an elongation of 67% till fracture. At the initial deformation stage, the dislocations were generated within the austenite grains, entangled and accumulated at the grain boundaries and annealing twin boundaries. Annealing twins participated in plastic deformation and hindered the dislocation movement. As the deformation progressed, the dislocation slip was hindered and produced stress concentration, and the stacking faults evolved into mechanical twins, which released the stress concentration and delayed the necking.

Similar content being viewed by others

References

S.S.M. Tavares, C.R. Rodrigues, C.A.S. de Oliveira, C.B. Woyames, J. Dille, J. Mater. Eng. Perform. 27 (2018) 1530–1536.

X.Q. Zhao, T. Pan, Q.F. Wang, H. Su, C.F. Yang, Q.X. Yang, J. Iron Steel Res. Int. 18 (2011) No. 5, 47–51.

Y.H. Yang, Q.W. Cai, H.B. Wu, H. Wang, Acta Metall. Sin. 45 (2009) 270–274.

C.K. Syn, J.W. Morris, S. Jin, Metall. Trans. A 7 (1976) 1827–1832.

M. Hoshino, N. Saitoh, H. Muraoka, O. Saeki, Nippon Steel Tech. Rep. 90 (2004) 20–24.

T. Kamo, K. Arimochi, T. Kawabata, K. Onishi, R. Andou, M. Yamashita, H. Iwahashi, N. Kubo, Y. Fuchimoto, M. Takata, N. Sakato, M. Mitsumoto, S. Hirai, H. Hirose, Y. Hagihara, ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Development of 7%Ni-TMCP Steel Plate for LNG Storage Tanks, Rotterdam, Netherlands, 2011, pp. 113–122.

S.Y. Han, S.Y. Shin, S. Lee, N.J. Kim, J.H. Kwak, K.G. Chin, Metall. Mater. Trans. A 42 (2011) 138–146.

H. Mohrbacher, M. Spöttl, J. Paegle, Adv. Manuf. 3 (2015) 3–18.

J. Lee, H. Kim, S.J. Park, J. Moon, H.N. Han, Mater. Sci. Eng. A 768 (2019) 138460.

P. Ren, X.P. Chen, Z.X. Cao, L. Mei, W.J. Li, W.Q. Cao, Q. Liu, Mater. Sci. Eng. A 752 (2019) 160–166.

D.W. Suh, S.J. Park, T.H. Lee, C.S. Oh, S.J. Kim, Metall. Mater. Trans. A 41 (2010) 397–408.

W.K. Choo, J.H. Kim, J.C. Yoon, Acta Mater. 45 (1997) 4877–4885.

G. Frommeyer, U. Brüx, Steel Res. Int. 77 (2006) 627–633.

J. Charles, A. Berghezan, A. Lutts, J. Phys. Colloques 45 (1984) C1-619–C1-623.

S.S. Sohn, B.J. Lee, S. Lee, N.J. Kim, J.H. Kwak, Acta Mater. 61 (2013) 5050–5066.

J.K. Kim, B.C. De Cooman, Mater. Sci. Eng. A 676 (2016) 216–231.

L.F. Zhang, R.B. Song, C. Zhao, F.Q. Yang, Y. Xu, S.G. Peng, Mater. Sci. Eng. A 643 (2015) 183–193.

S. Vercammen, B. Blanpain, B.C. De Cooman, P. Wollants, Acta Mater. 52 (2004) 2005–2012.

H. Kim, Y. Ha, K.H. Kwon, M. Kang, N.J. Kim, S. Lee, Acta Mater. 87 (2015) 332–343.

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, D. Barbier, Curr. Opin. Solid State Mater. Sci. 15 (2011) 141–168.

D.D. Li, L.H. Qian, C.Z. Wei, S. Liu, F.C. Zhang, J.Y. Meng, Mater. Sci. Eng. A 789 (2020) 139586.

H. Kim, J. Park, J.E. Jung, S.S. Sohn, S. Lee, Mater. Sci. Eng. A 641 (2015) 340–347.

D. Barbier, N. Gey, S. Allain, N. Bozzolo, M. Humbert, Mater. Sci. Eng. A 500 (2009) 196–206.

J. Chen, J.K. Ren, Z.Y. Liu, G.D. Wang, Mater. Sci. Eng. A 737 (2018) 158–165.

M.K. Dash, R. Mythili, A. Dasgupta, S. Saroja, Metall. Mater. Trans. A 49 (2018) 2843–2853.

L. Bracke, K. Verbeken, L. Kestens, J. Penning, Acta Mater. 57 (2009) 1512–1524.

S. Mahajan, C.S. Pande, M.A. Imam, B.B. Rath, Acta Mater. 45 (1997) 2633–2638.

S.R. Kalidindi, A.A. Salem, R.D. Doherty, Adv. Eng. Mater. 5 (2003) 229–232.

G. Dini, A. Najafizadeh, R. Ueji, S.M. Monir-Vaghefi, Mater. Des. 31 (2010) 3395–3402.

M.N. Shiekhelsouk, V. Favier, K. Inal, M. Cherkaoui. Int. J. Plast. 25 (2009) 105–133.

A. Rohatgi, K.S. Vecchio, G.T. GrayIII, Mater. Sci. Eng. A 32 (2001) 135–145.

O. Bouaziz, N. Guelton. Mater. Sci. Eng. A 319–321 (2001) 246–249.

S. Asgari, E. EI-Danaf, S.R. Kalidindi, R.D. Doherty, Metall. Mater. Trans. A 28 (1997) 1781–1795.

S.R. Kalidindi, Int. J. Plast. 14 (1998) 1265–1277.

O. Grassel, L. Krüger, G. Frommeyer, L.W. Meyer, Int. J. Plast. 16 (2000) 1391–1409.

L. Bracke, G. Mertens, J. Penning, B.C. De Cooman, M. Liebeherr, N. Akdut, Metall. Mater. Trans. A 37 (2006) 307–317.

X.Z. Liao, F. Zhou, E.J. Lavernia, S.G. Srinivasan, M.I. Baskes, D.W. He, Y.T. Zhu, Appl. Phys. Lett. 83 (2003) 632–634.

J. Park, M. Kang, S.S. Sohn, S.H. Kim, H.S. Kim, N.J. Kim, S. Lee, Mater. Sci. Eng. A 684 (2017) 54–63.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2017YFB0304900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Xt., Wu, Hb., Gu, Y. et al. Tensile deformation behavior of nickel-free high-manganese austenitic cryogenic-temperature steel. J. Iron Steel Res. Int. 29, 793–801 (2022). https://doi.org/10.1007/s42243-021-00612-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00612-3