Abstract

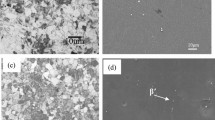

In this paper, the influence of the Sn element on the melt viscosity, grain size, shrinkage, and tensile properties of the sub-rapidly solidified Mg-6Al-4Zn alloy was studied. The results showed that the melt viscosity of the Mg-6Al-4Zn alloy was greatly decreased because of the addition of Sn. As the content of Sn increased from 0 to 1.8 wt.%, the grain size of the alloy was refined, and the dendrite microstructure was changed to rose-shaped ones simultaneously. The decreased melt viscosity and refined microstructure were conductive to the feeding of melt, which contributed to the reduction in volume fraction of shrinkage. The volume fraction of shrinkage of the Mg-6Al-4Zn-1.2Sn alloy was reduced by 30.8%, compared with that of the alloy without Sn addition. Tensile properties of the Mg-6Al-4Zn-xSn alloys were increased firstly and then decreased with the augmented Sn content. The yield strength, ultimate tensile strength, and elongation of the alloy containing 1.2 wt.% Sn were 21.4%, 39.5%, and 259.0% higher than those of the alloy without Sn addition, respectively. The addition of Sn was considered to reduce the shrinkage of the sub-rapidly solidified Mg-6Al-4Zn magnesium alloy and thus improved its tensile properties. To identify the mechanism, the effect of Sn on the volume fraction of shrinkage was discussed from three aspects of melt viscosity, grain refinement, and volume fraction of eutectic phases.

Similar content being viewed by others

References

W.J. Joost, P.E. Krajewski, Scr. Mater. 128, 107 (2017)

A.A. Luo, J. Magnes. Alloys 1, 2 (2013)

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai, M. Chakraborty, J. Alloys Compd. 456, 201 (2008)

P. Sharifi, Y. Fan, H.B. Anaraki, A. Banerjee, K. Sadayappan, J.T. Wood, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 47, 5159 (2016)

X. Li, S.M. Xiong, Z. Guo, J. Mater. Sci. Technol. 32, 54 (2016)

F. Wang, J.B. Li, J. Liu, D. Lv, P.L. Mao, Z. Liu, Acta Metall. Sin.-Engl. Lett. 27, 609 (2014)

P. Sharifi, J. Jamali, K. Sadayappan, J.T. Wood, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 49, 3080 (2018)

X. Li, S.M. Xiong, Z. Guo, J. Mater. Process. Technol. 231, 1 (2016)

X.B. Li, S.M. Xiong, Z.P. Guo, Acta Metall. Sin.-Engl. Lett. 29, 619 (2016)

M. Guanbao, A.V. Okhapkin, N.Y. Konstantinova, A.A. Sabirzyanov, P.S. Popel’, L. Pytsze, Russi. Metal. (Met.) 2013, 90 (2013)

O. Sedighi, S.G. Shabestari, F. Yavari, Thermochim. Acta 667, 165 (2018)

C.H. Ma, F.S. Pan, D.F. Zhang, A.T. Tang, Z.W. Lu, Acta Metall. Sin.-Engl. Lett. 34, 278 (2021)

Q. Zhang, W. Liu, G. Wu, L. Zhang, W. Ding, Acta Metall. Sin.-Engl. Lett. 33, 1505 (2020)

J.L. Du, A. Zhang, Z.P. Guo, M.H. Yang, M. Li, F. Liu, S.M. Xiong, J. Alloys Compd. 775, 322 (2019)

J.K. Kim, S.H. Oh, K.C. Kim, W.T. Kim, D.H. Kim, Mater. Trans. 58, 963 (2017)

X.Q. Pan, J.H. Chen, H.G. Yan, B. Su, J.Y. Wei, C. Fan, Mater. Sci. Technol. 29, 169 (2013)

J.H. Chen, J.Y. Wei, H.G. Yan, B. Su, X.Q. Pan, Mater. Des. 45, 300 (2013)

J. Wang, L.G. Wang, S.K. Guan, S.J. Zhu, C.X. Ren, S.S. Hou, J. Mater. Sci.-Mater. Med. 21, 2001 (2010)

H.R. Zhang, Z.B. Liu, Z.Z. Li, G.W. Li, H. Zhang, Acta Metall. Sin.-Engl. Lett. 29, 414 (2016)

H.P. Tang, Q.D. Wang, C. Lei, K. Wang, B. Ye, H.Y. Jiang, W.J. Ding, Acta Metall. Sin.-Engl. Lett. 32, 1549 (2019)

Y. Fu, H. Wang, C. Zhang, H. Hao, Mat. Sci. Eng. A-Struct. 723, 118 (2018)

B.K. Kang, I. Sohn, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 49, 5137 (2018)

M.B. Yang, F.S. Pan, Mater. Des. 31, 68 (2010)

Z. Zhang, A. Couture, A. Luo, Scr. Mater. 39, 45 (1998)

X.G. Dong, J.W. Fu, J. Wang, Y.S. Yang, Mater. Des. 51, 567 (2013)

V.B. Deev, E.S. Prusov, M. Shunqi, E.H. Ri, T.A. Bazlova, M.V. Temlyantsev, S.V. Smetanyuk, S.V. Ponomareva, K.N. Vdovin, Paper Presented at the International Workshop Advanced Technologies in Material Science, Mechanical and Automation Engineering (MIP)-Engineering, vol. 537 (IOP, England, 2019).

ASTM E112-13, Standard Test Methods for Determining Average Grain Size (West Conshohocken, PA, 2013)

ASTM E1245-03, Standard Practice for Determining the Inclusion or Second- Phase Constituent Content of Metals by Automatic Image Analysis (West Conshohocken, PA, 2016)

S. Morioka, Mat. Sci. Eng. A-Struct. 362, 223 (2003)

F. Zhang, Y. Du, S.H. Liu, W.Q. Jie, Calphad 49, 79 (2015)

L. Takamichi, I.L.G. Roderick, The Physical Properties of Liquid Metals (Clarendon Press, Oxford University, Oxford, 1988).

S. Morioka, J. Non-Cryst, Solids 341, 46 (2004)

Z.Y. Wang, Y.S. Yang, W.H. Tong, H.Q. Li, Z.Q. Hu, Acta Phys. Sin. 56, 1543 (2007)

A.R. Miedema, J. Less-Common Met. 46, 67 (1976)

A.R. Miedema, R. Boom, F.R. Deboer, J. Less-Common Met. 41, 283 (1975)

N. Kayama, K. Murali, S. Kiguchi, H. Satoh, Rep. Cast. Rese. Lab. 27, 1 (1976)

Y.C. Lee, A.K. Dahle, D.H. StJohn, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 31, 2895 (2000)

P.L. Zhang, Y.H. Zhao, R.P. Lu, Z.B. Ding, H. Hou, Acta Metall. Sin.-Engl. Lett. 32, 550 (2019)

P.Y. Wang, B.Y. Wang, C. Wang, J.G. Wang, C.Y. Ma, J.S. Li, M. Zha, H.Y. Wang, Mat. Sci. Eng. A-Struct. 791, 139696 (2020)

T. Cheng, L. Zhang, in Magnesium Technology 2020 ed. by J. B. Jordon, V. Miller, V. V. Joshi, N. R. Neelameggham. (Springer, Cham, 2020), pp. 269–279

E. Doernberg, A. Kozlov, R. Schmid-Fetzer, J. Phase Equilib. Diff. 28, 523 (2007)

M.W. Wu, S.M. Xiong, Acta Metall. Sin.-Engl. Lett. 46, 1534 (2010)

M.C. Flemings, presented at the F. Weinberg International Symposium on Solidification Processing (Pergamon, Oxford, 1990), p. 173

J. Cui, T.J. Luo, C. Wang, Y.J. Li, X.H. Feng, Q.Y. Huang, Y.S. Yang, Adv. Eng. Mater. 23, 2000583 (2021)

S. Shao, Y. Liu, C.S. Xu, Y.X. Xu, B. Wu, X.S. Zeng, X.F. Lu, X.J. Yang, Acta Metall. Sin.-Engl. Lett. 28, 7 (2015)

Q. Zhang, L. Chen, Q. Le, Spec. Cast. Nonferr. Alloys 36, 777 (2016)

M. Gao, G. He, T. Huang, C. Wang, C. Wu, G. Yu, Paper presented at the Advanced Manufacturing Technology, vol. 472–475, (Trans. Tech., Switzerland, 2012) p. 1082

Y. Fu, H. Wang, X.T. Liu, H. Hao, J. Rare Earth. 35, 503 (2017)

X. Li, S.M. Xiong, Z. Guo, Mat. Sci. Eng. A-Struct. 672, 216 (2016)

H.H. Yu, Y.C. Xin, M.Y. Wang, Q. Liu, J. Mater. Sci. Technol. 34, 248 (2018)

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2017YFB0103904), the Key Research and Development Project of Liaoning Province (No. 2019JH2/10100008), the National Key Research and Development Program of China (No. 2018YFE115800), and the Key Research and Development Plan of Shandong Province (No. 2019JZZY020329).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Cui, J., Luo, T., Li, Y. et al. Fluidity, Microstructure, and Tensile Properties of Sub-rapidly Solidified Mg-6Al-4Zn-xSn (x = 0, 0.6, 1.2, 1.8) Alloy. Acta Metall. Sin. (Engl. Lett.) 34, 1265–1276 (2021). https://doi.org/10.1007/s40195-021-01247-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01247-9