Abstract

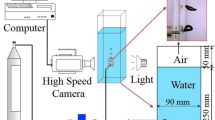

Water model experiments were carried out to investigate the bubble behavior in cylindrical and square vessels under centric mechanical stirring. The bubble behavior in the square vessel was investigated in detail by using a high-speed camera to record the transient images of the bubbles. An image analysis software was used to obtain the bubble diameter. The results showed that the centric mechanical stirring in the square vessel was suitable for breakage and dispersion of bubbles, but not suitable for that in the cylindrical vessel. Increasing the impeller blade length and impeller rotation speed was beneficial to disintegrate and disperse bubbles widely. The bubble diameter decreased with the increase in the Weber number and increased slightly with the increase in the modified Froude number. The dimensionless correlation equation of bubble diameter was obtained by the dimensional analysis method.

Similar content being viewed by others

References

T. Vuolio, V.V. Visuri, S. Tuomikoski, T. Paananen, T. Fabritius, Metall. Mater. Trans. B 49 (2018) 2692–2708.

X. Wang, S.G. Zheng, M.Y. Zhu, Ironmak. Steelmak. 47 (2020) 915–924.

W.J. Ma, H.B. Li, Y. Cui, B. Chen, G.L. Liu, J.L. Ji, ISIJ Int. 57 (2017) 214–219.

Y. Nakaguchi, T. Nakajima, Y. Sakai, Y. Ueda, M. Iguchi, ISIJ Int. 55 (2015) 326–328.

S. Yamaguchi, T. Uemura, H. Nashiwa, H. Sugita, Ironmak. Steelmak. 4 (1977) 276–279.

G.A. Irons, C. Celik, Ironmak. Steelmak. 19 (1992) 136–144.

V. Seshadri, C.A.D. Silva, I.A.D. Silva, P.V. Kruger, ISIJ Int. 37 (1997) 21–30.

H.J. Visser, R. Boom, ISIJ Int. 46 (2006) 1771–1777.

J. Yang, M. Kuwabara, K. Okumura, M. Sano, ISIJ Int. 45 (2005) 1795–1803.

W. Wu, W. Wu, Y.B. Hu, L. Liu, Y.L. Ding, J. Iron Steel Res. Int. 15 (2008) No. 1, 15–18.

K.F. Feng, A. Liu, K.J. Dai, S. Feng, J. Ma, J.Y. Xie, B. Wang, Y.W. Yu, J.Y. Zhang, Powder Technol. 314 (2017) 649–659.

E. Scheepers, J.J. Eksteen, C. Aldrich, Miner. Eng. 19 (2006) 1163–1173.

Y. Liu, Z.M. Zhang, M. Sano, J. Zhang, P. Shao, T.A. Zhang, J. Iron Steel Res. Int. 21 (2014) 135–143.

J.H. Ji, R.Q. Liang, J.C. He, ISIJ Int. 57 (2017) 453–462.

L.W. Xiao, K.S. Chen, B.B. Dan, Z.J. Rong, R. Wang, Adv. Mech. Eng. 8 (2016) No. 7, 1–11.

R.Q. Liang, J.H. Ji, J.C. He, J. Iron Steel Res. Int. 18 (2011) No. S2, 107–112.

Y. Liu, Z.M. Zhang, J.N. Liu, J.H. Zhang, M. Sano, J. Zhang, J. Iron Steel Res. Int. 20 (2013) 1–6.

Y. Liu, M. Sano, T.A. Zhang, Q. Wang, J.C. He, ISIJ Int. 49 (2009) 17–23.

Y. Liu, T.A. Zhang, M. Sano, Q. Wang, X.D. Ren, J.C. He, Trans. Nonferrous Metal. Soc. China. 21 (2011) 1896–1904.

Y. Liu, T.A. Zhang, M. Sano, Q. Wang, J.C. He, J. Iron Steel Res. Int. 18 (2011) No. S2, 166–171.

P.H. Calderbank, Trans. Inst. Chem. Engrs. 16 (1958) 443–453.

D.X. Wang, Y. Liu, Z.M. Zhang, P. Shao, T.A. Zhang, Math. Probl. Eng. 2016 (2016) 4170371.

J. Yang, M. Kuwabara, K. Okumura, M. Sano, Tetsu-to-Hagane 92 (2006) 246–253.

K. Okumura, M. Ban, M. Hirasawa, M. Sano, K. Mori, ISIJ Int. 35 (1995) 832–837.

T. Vermeulen, G.M. Williams, G.E. Langlois, Chem. Eng. Progr. 51 (1955) 85F.

Acknowledgements

This work was supported by the Key Technologies Research and Development Program (Nos. 2017YFC0210404 and 2017YFC0210403-04) and the National Natural Science Foundation of China (Nos. U1760120, U1710257, U1702253, and U1903129).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Dimensionless form of Calderbank equation is given below.

Under the conditions that the stirring power is completely dissipated using baffles, it can be expressed by

If the geometric similarity hold, the bath volume V is taken as

Then,

Ignoring the last term in Eq. (1), the Calderbank equation can be arranged as follows:

Thus, the power of the Weber number of Eq. (1) or Eq. (A4) (− 3/5) is similar to that of Eq. (6) (− 0.5). It is to be noted that the average diameter of droplets dispersed in liquid under mechanical stirring is proportional to We−3/5 [25].

Rights and permissions

About this article

Cite this article

Wang, K., Liu, Y., Sano, M. et al. Bubble behavior in cylindrical and square vessels under centric mechanical stirring. J. Iron Steel Res. Int. 28, 1243–1250 (2021). https://doi.org/10.1007/s42243-021-00609-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00609-y