Abstract

Background

Tapping is one of the processes that most requires attention in the industry, due to the stage in which it occurs and its characteristics. In the case of tapping, it is common to use components and equipment with less rigidity, which compromises the dynamic behavior in several situations and can lead to process distortion or failure.

Purpose

The objective of this paper is to study the dynamic behavior of tapping in relation to several characteristics of the process.

Methods

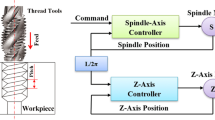

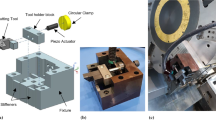

The dynamic behavior of the force signal was used to evaluate the process, varying the cutting parameters and the clamping system of the workpiece.

Results

The experimental results indicate that the floating system did not present a good dynamic behavior at high cutting speeds, this greater application of vibration is due to the resonance due to the combination of oscillations under forced and natural vibration.

Conclusions

The natural frequency of the floating fixture system influenced the behavior of the axial forces. The increase in cutting speed resulted in a direct increase in the axial force vibrations as its frequency came close to the natural frequency of the system. Through dynamic analysis of the axial force signal observed the dynamic characteristics of the process and the machine tool. This allowed the dynamic evaluation of the system through the measurement of force signals generated in the threading process.

Similar content being viewed by others

References

Landeta JF, Valdivielso AF, Lacalle LNL, Girot F, Pérez JM (2015) Wear of form taps in threading of steel cold forged parts. ASME J Manuf Sci Eng 137(3):031002. https://doi.org/10.1115/1.4029652

Hosseinabadi HAH, Altintas Y (2014) Modeling and active damping of structural vibrations in machine tools. CIRP J Manuf Sci Technol 7:246–257. https://doi.org/10.1016/j.cirpj.2014.05.001

Fromentin G, Poulachon G, Moisan A, Julien B, Giessler J (2005) Precision and surface integrity of threads obtained by form tapping. CIRP Ann 54:519–522. https://doi.org/10.1016/S0007-8506(07)60159-0

Pawar S, Joshi SS (2016) Experimental analysis of axial and torsional vibrations assisted tapping of titanium alloy. J Manuf Process 22:7–20. https://doi.org/10.1016/j.jmapro.2016.01.006

Zhao L, Chen H, Yao Y, Diao G (2016) A new approach to improving the machining precision based on dynamic sensitivity analysis. Int J Mach Tools Manuf 102:9–21. https://doi.org/10.1016/j.ijmachtools.2015.11.008

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools - a review Part II: thermal errors. Int J Mach Tools Manuf 40:1257–1284. https://doi.org/10.1016/S0890-6955(00)00010-9

Jensen SA, Shin YC (1999) Stability analysis in face milling operations Part 2: experimental validation and influencing factors. J Manuf Sci Eng Transact ASME 121:605–615. https://doi.org/10.1115/1.2833076

Ma YC, Wan M, Yang Y, Zhang WH (2019) Dynamics of tapping process. Int J Machine Tools Manuf 140:34–47. https://doi.org/10.1016/j.ijmachtools.2019.02.002

Eynian M (2014) Frequency domain study of vibrations above and under stability lobes in machining systems. Procedia CIRP 14:164–169. https://doi.org/10.1016/j.procir.2014.03.068

WEINGAERTNER W L, SCHROETER R B, POLLI M L, GOMES J O. (2007) The influence of cutting parameters on dynamic stability in spherical top milling at high speeds. COBEF 2007, Brazilian Congress of Manufacturing Engineering.

Pandian PP, Raja VP, Sakthimurugan K (2012) Identification of stability lobes in high-speed machining of thin ribs. Research Inventy Int J Eng Sci 1:01–06

R Kalidasan V Ramanuj DK Sarma S Senthilvelan 2014 Influence of cutting speed and offset distance over cutting tool vibration in multi-tool turning process. Adv Materials Res 984 100 105 https://doi.org/10.4028/www.scientific.net/AMR.984-985.100

NAVES V T G, SILVA M B. (2010) Study of the usability of gray cast iron linked to CrCuSn and CrCuSnMo and vermicular class 350 by monitoring vibration signals and cutting power. CONEM 2010, VI Brazilian Congress of Manufacturing Engineering.

SOUZA A J, SCHROETER R B. (2007) Analysis of the influence of the cut parameters on the monitored signals of force and vibration, and on the variation of the roughness of the turned surface. COBEF 2007, Brazilian Congress of Manufacturing Engineering.

Duarte MAV, Meola T, Souza MM, Silva MB. (2003) Monitoring the drilling process on a CNC mill using mechanical vibration signals. ABCM 2003, Associação Brasileira de Ciências Mecânicas.

Wan M, Ma YC, Feng J, Zhang WH (2017) Mechanics of tapping process with emphasis on measurement of feed error and estimation of its induced indentation forces. Int J Mach Tools Manuf 102:8–20. https://doi.org/10.1016/j.ijmachtools.2016.12.003

Norton RL (2013) Machine Design: An Integrated Approach. Prentice Hall, New York

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pereira, I.C., Mapa, L.d.P., de Barros, T.N. et al. Dynamic Behavior of Tapping Axial Force. J. Vib. Eng. Technol. 9, 1499–1509 (2021). https://doi.org/10.1007/s42417-021-00310-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-021-00310-0