Abstract

A maintenance policy and the management of the inventory of spare parts and their joint optimization often challenge managers and researchers. In this paper, the first analytical joint optimization model is established. A simulation model is then developed for the system operating under the suggested condition-based maintenance to optimize the maintenance outline of mining dump truck motors based on oil monitoring. Our model is combined with a genetic algorithm to obtain the optimal response. In the presented model, the Inspection intervals (\(T\)) and the maximum stock level (\(S\)) are jointly optimized for minimizing cost. To build a sample and a simulation of various repair events, 11,000 oil analysis data is used. The deterioration of spare parts is shown with an increasing numerical variable over time, which follows a function. Using the existing datasets, the deterioration rate function is obtained. Another process required for simulation is the failure probability function. Due to the extent of deterioration with various breakdowns, there are uncertainties and different values. Condition-based maintenance is used to determine the deterioration level of failure. In the end, the results of the simulation are compared with the current costs resulting from the workshop policies.

Similar content being viewed by others

References

Alaswad S, Xiang Y (2017) A review on condition-based maintenance optimization models for stochastically deteriorating system. Reliab Eng Syst Saf 157:54–63

Azadivar F, Tompkins G (1999) Simulation optimization with qualitative variables and structural model changes: a genetic algorithm approach. Eur J Oper Res 113(1):169–182

Bayle T (2007) Preventive maintenance strategy for data centers. American Power Conversion, USA

Bevilacqua M, Braglia M (2000) The analytic hierarchy process applied to maintenance strategy selection. Reliab Eng Syst Saf 70(1):71–83

Bianchini A, Pellegrini M, Rossi J (2019) Maintenance scheduling optimization for industrial centrifugal pumps. Int J Syst Assur Eng Manag 10(4):848–860

Bianchini A, Rossi J, Antipodi L (2018) A procedure for condition-based maintenance and diagnostics of submersible well pumps through vibration monitoring. Int J Syst Assur Eng Manag 9(5):999–1013

Braglia M, Grassi A, Montanari R (2004) Multi-attribute classification method for spare parts inventory management. J Qual Maint Eng 10(1):55–65. https://doi.org/10.1108/13552510410526875

Chen Y-K, Gao Q, Su X-B, Fang S, Guo CM (2018) Research on optimization of spare parts inventory policy considering maintenance priority. Int J Syst Assur Eng Manag 9(6):1336–1345

Coolen FPA, Dekker R (1995) Analysis of a 2-phase model for optimization of condition-monitoring intervals. IEEE Trans Reliab 44(3):505–511. https://doi.org/10.1109/24.406593

Cox DR (1972a) Regression models and life-tables. J R Stat Soc: Ser B (methodol) 34(2):187–202. https://doi.org/10.1111/j.2517-6161.1972.tb00899.x

Cox DR (1972b) Regression models and life-tables. J R Stat Soc: Ser B (methodol) 34(2):187–202

Deb K, Agrawal S, Pratap A, Meyarivan T (2000) A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In: International conference on parallel problem solving from nature. Springer, pp 849–858

Dohi T, Kaio N, Osaki S (1998) On the optimal ordering policies in maintenance theory—survey and applications. Appl Stoch Models Data Anal 14(4):309–321

Grall A, Bérenguer C, Dieulle LJRE, Safety S (2002) A condition-based maintenance policy for stochastically deteriorating systems. Reliab Eng Syst Saf 76(2):167–180

Ilgin MA, Tunali S (2006) Joint optimization of spare parts inventory and maintenance policies using genetic algorithms. Int J Adv Manuf Technol 34(5–6):594–604. https://doi.org/10.1007/s00170-006-0618-z

Ilgin MA, Tunali S (2007) Joint optimization of spare parts inventory and maintenance policies using genetic algorithms. Int J Adv Manuf Technol 34(5):594–604. https://doi.org/10.1007/s00170-006-0618-z

Jardine A, Banjevic D, Wiseman M, Buck S, Joseph T (2001) Optimizing a mine haul truck wheel motors’ condition monitoring program Use of proportional hazards modeling. J Qual Maint Eng 7(4):286–302

Jiang Y, Chen M, Zhou D (2015) Joint optimization of preventive maintenance and inventory policies for multi-unit systems subject to deteriorating spare part inventory. J Manuf Syst 35:191–205

Kabir AZ, Al-Olayan AS (1996) A stocking policy for spare part provisioning under age based preventive replacement. Eur J Oper Res 90(1):171–181

Zohrul Kabir ABM, Al‐Olayan AS (1994) Joint optimization of age replacement and continuous review spare provisioning Policy. Int J Oper Prod Manag 14(7):53–69

Kolarik W (1988) Performance reliability. Unpublished working paper, Department of Industrial Engineering, Texas Tech University

Leou R-C (2001) A flexible unit maintenance scheduling considering uncertainties. IEEE Trans Power Syst 16(3):552–559

Lin Y, Bian Z, Liu X (2016) Developing a dynamic neighborhood structure for an adaptive hybrid simulated annealing–tabu search algorithm to solve the symmetrical traveling salesman problem. Appl Soft Comput 49:937–952

Lu H, Kolarik WJ, Lu SS (2001) Real-time performance reliability prediction. IEEE Trans Reliab 50(4):353–357

Lu S (1999) System self-assessment of performance reliability in multivariate time series modeling. Texas Tech University Lubbock, Texas

Magnier L, Haghighat F (2010) Multiobjective optimization of building design using TRNSYS simulations, genetic algorithm, and Artificial Neural Network. Build Environ 45(3):739–746

Mann L, Saxena A, Knapp GM (1995) Statistical-based or condition-based preventive maintenance? J Qual Maint Eng 1(1):46–59

Marseguerra M, Zio E, Podofillini L (2002) Condition-based maintenance optimization by means of genetic algorithms and Monte Carlo simulation. Reliab Eng Syst Saf 77(2):151–165

Marseguerra M, Zio E, Podofillini L (2005) Multiobjective spare part allocation by means of genetic algorithms and Monte Carlo simulation. Reliab Eng Syst Saf 87(3):325–335

Mishra R, Pathak K (2012) Maintenance engineering and management: PHI Learning Pvt. Ltd.

Mohanty JK, Dash PR, Pradhan PK (2020) FMECA analysis and condition monitoring of critical equipments in super thermal power plant. Int J Syst Assur Eng Manag 11:583–599

Peng Y, Dong M, Jian Zuo M (2010) Current status of machine prognostics in condition-based maintenance: a review. Int J Adv Manuf Technol 50(1–4):297–313

Safari E, Sadjadi SJ, Shahanaghi K (2010) Scheduling flowshops with condition-based maintenance constraint to minimize expected makespan. Int J Adv Manuf Technol 46(5–8):757–767

Saha R, Azeem A, Hasan KW et al (2021) Integrated economic design of quality control and maintenance management: Implications for managing manufacturing process. Int J Syst Assur Eng Manag 12:263–280

Samora I, Franca MJ, Schleiss AJ, Ramos HM (2016) Simulated annealing in optimization of energy production in a water supply network. Water Resour Manage 30(4):1533–1547

Sarker R, Haque A (2000) Optimization of maintenance and spare provisioning policy using simulation. Appl Math Model 24(10):751–760

Sharma P, Saxena K (2017) Application of fuzzy logic and genetic algorithm in heart disease risk level prediction. Int J Syst Assur Eng Manag 8(2):1109–1125

Sheu S-H, Chien Y-H (2004) Optimal age-replacement policy of a system subject to shocks with random lead-time. Eur J Oper Res 159(1):132–144

Sheu S-H, Griffith WS (2001) Optimal age-replacement policy with age-dependent minimal-repair and random-leadtime. IEEE Trans Reliab 50(3):302–309

Shum Y-S, Gong D-C (2007) The application of genetic algorithm in the development of preventive maintenance analytic model. Int J Adv Manuf Technol 32(1–2):169–183

Teplý B (2014) Interrelation among service life, reliability index, and costs of concrete structures subjected to aggressive exposure. J Perform Constr Facil 28(4):04014003

Wang H (2002) A survey of maintenance policies of deteriorating systems. Eur J Oper Res 139(3):469–489

Wang J, Qiu Q, Wang H (2021) Joint optimization of condition-based and age-based replacement policy and inventory policy for a two-unit series system. Reliab Eng Syst Saf 205:107251

Wang L, Chu J, Mao W (2009) A condition-based replacement and spare provisioning policy for deteriorating systems with uncertain deterioration to failure. Eur J Oper Res 194(1):184–205

Wang W (2003) Modelling condition monitoring intervals: a hybrid of simulation and analytical approaches. J Oper Res Soc 54(3):273–282. https://doi.org/10.1057/palgrave.jors.2601508

Wang Z, Wong Y, Rahman M (2004) Optimisation of multi-pass milling using genetic algorithm and genetic simulated annealing. Int J Adv Manuf Technol 24(9–10):727–732

Wireman T (1990) World class maintenance management. Industrial Press, New York

Wiseman M (2001) Optimizing condition based maintenance. Plant Eng Maint 23(6):57–71

Yan T, Lei Y, Wang B, Han T, Si X, Li N (2020) Joint maintenance and spare parts inventory optimization for multi-unit systems considering imperfect maintenance actions. Reliab Eng Syst Saf 202:106994. https://doi.org/10.1016/j.ress.2020.106994

Yang R, Kang J (2017) A joint optimal policy of block preventive replacement and spare part inventory. Int J Syst Assur Eng Manag 8(4):740–746

Zhao Y, Cao X, Gao J, Sun Y, Yang H, Liu X et al (2016) Broadband diffusion metasurface based on a single anisotropic element and optimized by the simulated annealing algorithm. Sci Rep 6:23896

Zohrul Kabir ABM, Al-Olayan AS (1996) A stocking policy for spare part provisioning under age based preventive replacement. Eur J Oper Res 90(1):171–181. https://doi.org/10.1016/0377-2217(94)00246-0

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

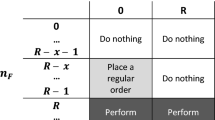

In general, in this model, we perform the following steps:

Research methodology flow chart

Rights and permissions

About this article

Cite this article

Motahari, R., Saeidi Sough, Y., Aboutorab, H. et al. Joint optimization of maintenance and inventory policies for multi-unit systems. Int J Syst Assur Eng Manag 12, 587–607 (2021). https://doi.org/10.1007/s13198-021-01123-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01123-w