Abstract

The influence of a degree of strain by rotary forging, as well as post-deformation annealing on the structure and mechanical properties of a clad aluminum alloy/copper bimetallic material was studied. Rotary forging of the initial bimetallic billet was carried out step by step from a diameter of 20.1 mm to a diameter of 2.4 mm. Rotary forging of the aluminum alloy/copper bimetallic material to a diameter of 5.3 mm leads to the formation of a mixed fine-grained and nanocrystalline oriented structure in an aluminum shell and to a decrease in the average grain size by 4.5 times and to an increase in the density of crystalline defects in a copper core. A reduction in the aluminum alloy/copper bimetallic material diameter to 2.4 mm (with intermediate annealing) leads to the formation of a fine-grained elongated grain-subgrain oriented structure in the aluminum shell and to the formation of a mixed cellular and subgrain structure in a copper core. Rotary forging leads to a significant increase in the strength of the aluminum alloy/copper bimetallic material and to a decrease in ductility. The optimal combination of increased strength and satisfactory ductility provides post-deformation annealing.

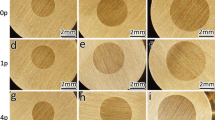

Graphic Abstract

Similar content being viewed by others

Availability of data and material

None.

References

M.F. Ashby, Y.J.M. Brechet, Acta Mater. 51, 5801 (2003)

H.H. Kim, M.S. Lee, C.G. Kang, Mater. Manuf. Process. 28, 892 (2013)

O. Bouaziz, Scripta Mater. 68, 28 (2013)

A. Molotnikov, R. Gerbrand, O. Bouaziz, Y. Estrin, Adv. Eng. Mater. 15, 728 (2013)

A.Y. Nalivaiko, A.N. Arnautova, S.V. Zmanovsky, D.Y. Ozherelkov, P.K. Shurkin, A.A. Gromov, J. Alloy. Compd. 825, 154024 (2020)

S. Mondal, Aluminum or Its Alloy Matrix Hybrid Nanocomposites. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00750-5

I.-K. Kim, S.I. Hong, Mater. Design 47, 590 (2013)

M. Zebardast, A.K. Taheri, J. Mater. Process. Tech. 211, 1034 (2011)

N. Ahmed, J. Mech. Work. Technol. 2, 19 (1978)

Y. Mitani, H. Balmori, in Strength of Metals and Alloys (ICSMA 6), Proceedings of the 6th International Conference, Melbourne, Australia, August 16-20, 1982 (Pergamon Press, Oxford, 1983), pp. 983–988

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov, Prog. Mater. Sci. 45, 103 (2000)

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, Y.T. Zhu, Mater. Res. Lett. 4, 1 (2016)

R.Z. Valiev, A.P. Zhilyaev, T.G. Langdon, Bulk Nanostructured Materials: Fundamentals and Applications (Wiley, New Jersey, 2014)

I.V. Alexandrov, Met. Mater. Int. 7, 565 (2001)

Y. Beygelzimer, Y. Estrin, R. Kulagin, Adv. Eng. Mater. 17, 1853 (2015)

O. Bouaziz, H.S. Kim, Y. Estrin, Adv. Eng. Mater. 15, 336 (2013)

S.O. Rogachev, S.A. Nikulin, A.B. Rozhnov, V.M. Khatkevich, T.A. Nechaykina, M.V. Gorshenkov, R.V. Sundeev, Metall. Mater. Trans. A 48, 6091 (2017)

R. Lapovok, V.V. Popov Jr., Y. Qi, A. Kosinova, A. Berner, C. Xu, E. Rabkin, R. Kulagine, J. Ivanisenko, B. Baretzky, O.V. Prokof’eva, A.N. Sapronov, D.V. Prilepo, Y. Beygelzimer, Mater. Design 187, 108398 (2020)

Z. Gronostajski, Z. Pater, L. Madej, A. Gontarz, L. Lisiecki, A. Lukaszek-Solek, J. Luksza, S. Mróz, Z. Muskalski, W. Muzykiewicz, M. Pietrzyk, R.E. Sliwa, J. Tomczak, S. Wiewiórowska, G. Winiarski, J. Zasadzinski, S. Ziólkiewicz, Arch. Civ. Mech. Eng. 19, 898 (2019)

V.A. Andreev, V.S. Yusupov, M.M. Perkas, V.V. Prosvirnin, A.E. Shelest, S.D. Prokoshkin, IYu. Khmelevskaya, A.V. Korotitskii, S.A. Bondareva, R.D. Karelin, Russ. Metall. 2017, 890 (2017)

S.A. Nikulin, T.A. Nechaikina, A.B. Rozhnov, S.O. Rogachev, VYu. Turilina, Met. Sci. Heat Treat. 60, 229 (2018)

S. Prokoshkin, I. Khmelevskaya, V. Andreev, R. Karelin, V. Komarov, A. Kazakbiev, Mater. Sci. Forum 918, 71 (2018)

R. Kocich, L. Kunčická, C.F. Davis, T.C. Lowe, I. Szurman, A. Macháčková, Mater. Design 90, 379 (2016)

L. Kunčická, R. Kocich, K. Dvořák, A. Macháčková, Mater. Sci. Eng. A 742, 743 (2019)

E.V. Avtokratova, S.V. Krymskiy, M.V. Markushev, O.S. Sitdikov, Lett. Mater. 1, 92 (2011)

G. Angella, P. Bassani, A. Tuissi, D. Ripamonti, M. Vedani, Mater. Sci. Forum 503-504, 493 (2006)

M.H. Shaeri, M. Shaeri, M. Ebrahimi, M.T. Salehi, S.H. Seyyedein, Prog. Nat. Sci. Mater. Int. 26, 182 (2016)

S.O. Rogachev, V.A. Andreev, V.S. Yusupov, V.M. Hatkevich, E.V. Nikolaev, M.M. Perkas, S.A. Bondareva, Met. Sci. Heat Treat. 62, 748 (2021)

A.M. Glezer, R.V. Sundeev, Mater. Lett. 139, 455 (2015)

A.M. Glezer, L.S. Metlov, Phys. Solid State 52, 1162 (2010)

E.D. Khafizova, I.P. Iskandarova, P.K. Islamgaliev, D.L. Pankratov, Lett. Mater. 5, 399 (2015)

H.J. Roven, M. Liu, J.C. Werenskiold, Mater. Sci. Eng. A 483–484, 54 (2008)

B. Straumal, A. Korneva, P. Zieęba, Arch. Civ. Mech. Eng. 14, 242 (2014)

B.B. Straumal, V. Pontikis, A.R. Kilmametov, A.A. Mazilkin, S.V. Dobatkin, B. Baretzky, Acta Mater. 122, 60 (2017)

E. Khafizova, R. Islamgaliev, G. Klevtsov, E. Merson, Mater. Phys. Mech. 24, 232 (2015)

A.A. Mazilkin, B.B. Straumal, A.R. Kilmametov, T. Boll, B. Baretzky, O.A. Kogtenkova, A. Korneva, P. Zięba, Scripta Mater. 173, 46 (2019)

Acknowledgements

The aluminum alloy/copper bimetallic material forging process was carried out as part of the state assignment IMET RAS No. 075-00947-20-00. Investigation of the aluminum alloy/copper bimetallic material was carried out with partial financial support from the Ministry of Science and Higher Education of the Russian Federation in the framework of Increase Competitiveness Program of NUST MISIS (No. К2-2019-008), implemented by a governmental decree dated 16th of March 2013, N 211. The authors thank A.A. Tokar for help in preparing samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Code availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rogachev, S.O., Andreev, V.A., Yusupov, V.S. et al. Effect of Rotary Forging on Microstructure Evolution and Mechanical Properties of Aluminum Alloy/Copper Bimetallic Material. Met. Mater. Int. 28, 1038–1046 (2022). https://doi.org/10.1007/s12540-020-00964-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00964-7