Abstract

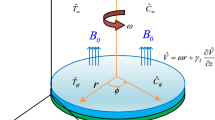

This research article intends to investigate the entropy generation in the context of unsteady thermocapillary convection of a hybrid nanoliquid thin film over a disk within magnetohydrodynamic considerations. A set of partial differential equations using Prandtl’s boundary layer theory has been written to present the flow situation in mathematical form. Irreversible processes of viscous and Joule dissipations have been considered in the temperature balance equation. A suitable choice of transform variables facilitate a system of ODEs from original PDEs representing the flow phenomena. This system of ODEs is solved by shooting technique in conjunction with Runga-Kutta 4th-order numerical scheme. The physical observations for velocity, temperature and quantities of engineering quantities are well presented using graphs and tables. One of the significant results of this study shows that with the use of blade shaped nanoparticles of both kind, maximum heat transfer at the disk surface is achieved and it is least when spherical shaped nanoparticles are used.

Similar content being viewed by others

References

S U S Choi Proc. ASME Int. Mech. Engg. Cong. Expos. 66 1995 (1995)

H Masuda, A Ebata, K Teramae and N Hishinuma J-STAGE 4 227 (1993)

J A Eastman, S U S Choi, S Li and L Thompson AIP 78 718 (2001)

M Shahzad, M Ali, F Sultan, W A Khan and Z Hussain Ind. J. Physics, https://doi.org/10.1007/s12648-019-01669-3 (2019)

M Ali, M Shahzad, F Sultan, W A Khan and S Rashid Int. Comm. Heat Mass Transf. 116 (2020)

S Khan, W Shu, M Ali, F Sultan and M. Shahzad App. Nanoscience 10 5391 (2020)

B Kumar, G S Seth and R Nandkeolyar Proc. Ins. Mech. Eng., E: J. Pro. Mech. Eng. 234 3 (2020)

M Ali, M Shahzad, F Sultan, W A Khan and S Z H Shah App. Nanoscience https://doi.org/10.1007/s13204-020-01532-6 (2020)

M Ali, M Shahzad, F Sultan and W A Khan App. Nanoscience 10 3259 (2020)

S Kakac and A Pramuanjaroenkij Int. J. Heat Mass Transf. 52 3187 (2009)

F Selimefendigil and A J Chamkha Int. J. Comp. Ther. Sci. 8 555 (2016)

M Sheikholeslami, S Mehryan, A Shafee and M A Sheremet J. Molecular Liq. 277 388 (2019)

S Shehzad, M Sheikholeslami, T Ambreen, A Shafee, H Babazadeh and M Ahmad App. Nanoscience https://doi.org/10.1007/s13204-020-01432-9 (2020)

Y Ma, R Mohebbi, M Rashidi and Z Yang J. Thermal Analysis and Calorimetry 136 1723 (2019)

A Bejan, Energy, 5 720 (1980)

M Ishaq, G Ali, Z Shah, S Islam and S Muhammad Entropy, 20 412 (2018)

U Farooq, M I Afridi, M Qasim and D C Lu Entropy, 20 668 (2018)

A Kumar, R Tripathi and R Singh, J. Brazilian Soc. Mech. Sci. and Eng., 41 306 (2019)

F Sultan, W A Khan, M Ali, M Shahzad, H Sun and M. Irfan J. Brazilian Soc. Mech. Sci. Eng. 41 439 (2019)

J Wang, W A Khan, Z Asghar, M Waqas, M Ali and M. Irfan Comp. Meth. Prog. Biomed. 188 105274 (2020)

M Ali, F Sultan, W A Khan and M, Shahzad App. Nanoscience 10, 3215 (2020)

M M Rashidi, S Abelman and N F Mehr Int. J. Heat and Mass Transf., 62 515 (2013)

G R Kefayati and H Tang Int. J. Heat and Mass Transf., 131 346 (2019)

A Kumar, R Tripathi, R Singh and Mikhail A Sheremet, Ind. J. Physics https://doi.org/10.1007/s12648-020-01800-9 (2020)

A Sakly and F B Nejma App. App. Thermal Eng., 171 114903 (2020).

I Pozoga and J Diakun POLIMERY 56 845 (2014)

C Y Wang Quarterly App. Math 48 601 (1990)

Y Komoda, Y Inoue and Y Hirata J. Chemical Eng. Japan 33 879 (2000)

N S Khan, S Islam, T Gul, I Khan, W Khan and L Ali Alexandria Engineering Journal, 57 1019 (2018)

A Ullah, Z Shah, P Kumam, M Ayaz, S Islam and M Jameel, processes, 7 262 (2019)

B S Dandapat, B Santra and K Vajravelu Int. J. Heat and Mass Trans. 50 991 (2007)

J R A Pearson J. Fluid Mech. 4 489 (1958)

A Cazabat, F Heslot, S Troian and P Carles Nature 346 824 (1990)

E Magyari and A J Chamkha Int. J. Heat and Mass Trans. 43 965 (2007)

C Jiao, L Zheng, Y Lin, L Ma and G Chen Int. J. Heat and Mass Trans. 92 700 (2016)

M Narula, M A Abdou, A Y Ying, T Sketchley and J Burris 20th IEEE/NPSS Symposium, 2-5 244 (2003)

I Hashim and S K Wilson Acta Mechanica 132 129 (1999)

S M Ibrahim Int. J. Eng. Math., 2013 Article ID 903818 (2013)

B Mahanthesh, B J Gireesha, N S Shashikumar and S A Shehzad Physica E: Low-dim. Sys. and Nanostructures, 94 25(2017)

T Gul, R Akbar, Z Zaheer and I S Amiri Proc. Inst. Mechanical Eng., Part N: J. Nanomaterials, Nanoeng. and Nanosys., 234 37 (2019)

T Hayat, M Rashid, M Imtiaz and A Alsaedi AIP Advances 5 067169 (2015)

Z Shah, E O Alzahrani, W Alghamdi and M Z Ullah. J. Therm. Analy. and Calorimetry https://doi.org/10.1007/s10973-019-09176-7

A Bhattad and J Sarkar J. Thermal Analy. and Calorimetry. pp. 13 (2019) https://doi.org/10.1007/s10973-019-09146-z

S Naseer, T Gul, S Islam and I Khan AIP Advances 9 095306 https://doi.org/10.1063/1.5053409 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tripathi, R., Chaurasiya, V.K., Kumar, A. et al. Minimization of entropy production in the transient thermocapillary flow of \(Al_2O_3 - Cu\) hybrid nanoliquid film over a disk. Indian J Phys 96, 1465–1479 (2022). https://doi.org/10.1007/s12648-021-02100-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-021-02100-6