Abstract

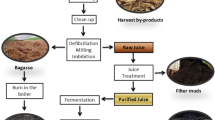

Biorefineries from paddy residues (rice straw and rice husk) have a high potential to satisfy human society’s need for sustainable fuel and chemical production. Biorefinery systems should be created in a sustainable and eco-friendly manner, accompanying the safe disposal of waste stream produced during processing. This study developed a pilot-scale biorefinery, whose bioethanol production from rice straw was an integrated recovery system for lignin, silica, and nutrient recovery. The recovery yield of silica and lignin from the black liquor of alkaline pretreatment was up to 96%, and the lignin purity reached 79% without the existence of carbohydrate fiber. After the recovery, the final liquid waste mainly contained inorganic matters and has a potential to be reused in the acidification step. The distillation residue was a nitrogen source for simultaneous saccharification and fermentation equivalent to corn steep liquor with the final ethanol concentration of 1.6 wt% in 160 h. The new process can be considered as a zero-waste biorefinery model. The material flow indicated that more valued products produced by the simple method increase the profits of this process. Also, the energy efficiency of the process was 0.53 that demonstrated the process’s economy and sustainability. The proposed system was feasible to foster the sustainable integration of local agricultural development and biomass industry shortly.

Graphic abstract

Similar content being viewed by others

Change history

24 May 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10098-021-02116-w

References

Abraham A, Mathew AK, Sindhu R et al (2016) Potential of rice straw for bio-refining: an overview. Bioresour Technol 215:29–36

Aresta M, Dibenedetto A, Dumeignil F (2012) Biorefinery: from biomass to chemicals and fuels. Walter de Gruyter, Berlin

Bedhief I, Foschini L, Bellavista P et al (2019) Toward self-adaptive software defined fog networking architecture for IIoT and industry 4.0. In: 2019 IEEE 24th international workshop on computer aided modeling and design of communication links and networks (CAMAD). IEEE, pp 1–5

Bruins ME, Sanders JPM (2012) Small-scale processing of biomass for biorefinery. Biofuels Bioprod Biorefining 6:135–145

Chiew YL, Cheong KY (2011) A review on the synthesis of SiC from plant-based biomasses. Mater Sci Eng B 176:951–964

de Jong E, Higson A, Walsh P, Wellisch M (2012) Bio-based chemicals value added products from biorefineries. IEA Bioenergy, Task42 Biorefinery, 34

Do NH, Pham HH, Le TM et al (2020) The novel method to reduce the silica content in lignin recovered from black liquor originating from rice straw. Sci Rep 10:21263. https://doi.org/10.1038/s41598-020-77867-5

Dowe N, McMillan J (2008) SSF experimental protocols-lignocellulosic biomass hydrolysis and fermentation. NREL chemical analysis and testing laboratory analytical procedures. 2008. NREL/TP-510-42630

Esteves B, Velez Marques A, Domingos I, Pereira H (2013) Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas Cienc y Tecnol 15:245–258. https://doi.org/10.4067/S0718-221X2013005000020

Farinas CS, Marconcini JM, Mattoso LHC (2018) Enzymatic conversion of sugarcane lignocellulosic biomass as a platform for the production of ethanol, enzymes and nanocellulose. J Renew Mater 6:203–216

García A, Toledano A, Serrano L et al (2009) Characterization of lignins obtained by selective precipitation. Sep Purif Technol 68:193–198. https://doi.org/10.1016/j.seppur.2009.05.001

Hatti-Kaul R (2010) Biorefineries–a path to sustainability? Crop Sci 50:S-152

Jeelani PG, Mulay P, Venkat R, Ramalingam C (2020) Multifaceted application of silica nanoparticles. A review. SILICON 12:1337–1354

Kargbo FR, Xing J, Zhang Y (2010) Property analysis and pretreatment of rice straw for energy use in grain drying: a review. Agric Biol JN Am 1:195–200

Katakojwala R, Mohan SV (2021) A critical view on the environmental sustainability of biorefinery systems. Curr Opin Green Sustain Chem 27:100392. https://doi.org/10.1016/j.cogsc.2020.100392

Kauldhar BS, Yadav SK (2018a) Turning waste to wealth: a direct process for recovery of nano-silica and lignin from paddy straw agro-waste. J Clean Prod 194:158–166

Kauldhar BS, Yadav SK (2018b) Turning waste to wealth: a direct process for recovery of nano-silica and lignin from paddy straw agro-waste. J Clean Prod 194:158–166. https://doi.org/10.1016/j.jclepro.2018.05.136

Kaur A, Kuhad RC (2019) Valorization of rice straw for ethanol production and lignin recovery using combined acid-alkali pre-treatment. BioEnergy Res 12:570–582

Khaleghian H, Molaverdi M, Karimi K (2017) Silica removal from rice straw to improve its hydrolysis and ethanol production. Ind Eng Chem Res 56(35):9793–9798. https://doi.org/10.1021/acs.iecr.7b02830

Khanh LV, Tran UPN, Nguyen QD et al (2015) Self-reuse of distillation residue as a nitrogen source for simultaneous saccharification and fermentation in a bioethanol production process from rice straw. Environ Sci 28:335–342

Kim M, Kim B-C, Nam K, Choi Y (2018) Effect of pretreatment solutions and conditions on decomposition and anaerobic digestion of lignocellulosic biomass in rice straw. Biochem Eng J 140:108–114. https://doi.org/10.1016/j.bej.2018.09.012

Kolfschoten RC, Bruins ME, Sanders JPM (2014) Opportunities for small-scale biorefinery for production of sugar and ethanol in the Netherlands. Biofuels Bioprod Biorefining 8:475–486

Kopani M, Mikula M, Kosnac D et al (2017) Morphology and FT IR spectra of porous silicon. J Electr Eng 68:53–57. https://doi.org/10.1515/jee-2017-0056

Le PK, Le TDT, Nguyen QD et al (2020) Process simulation of the pilot scale bioethanol production from rice straw by Aspen Hysys. In: IOP conference series: materials science and engineering. IOP Publishing, p 12095

Lucke D, Constantinescu C, Westkämper E (2008) Smart factory-a step towards the next generation of manufacturing. In: Manufacturing systems and technologies for the new frontier. Springer, pp 115–118

Mills S, Lucas S, Irakliotis L et al (2012) Demystifying big data: a practical guide to transforming the business of government. TechAmerica Foundation, Washington

Minu K, Jiby KK, Kishore VVN (2012) Isolation and purification of lignin and silica from the black liquor generated during the production of bioethanol from rice straw. Biomass Bioenergy 39:210–217. https://doi.org/10.1016/j.biombioe.2012.01.007

Mochidzuki K, Sato N, Sakoda A, Tuan PD (2006) Development of local biomass-based fuel systems in Mekong Delta area. In: AIChE annual meeting, conference proceedings

Nakyai T, Saebea D (2019) Exergoeconomic comparison of syngas production from biomass, coal, and natural gas for dimethyl ether synthesis in single-step and two-step processes. J Clean Prod 241:118334

Quispe I, Navia R, Kahhat R (2017) Energy potential from rice husk through direct combustion and fast pyrolysis: a review. Waste Manag 59:200–210

Rajkumar R, Lee I, Sha L et al (2010) Cyber-physical systems: the next computing revolution. In: Design Automation Conference, pp 731–736. https://doi.org/10.1145/1837274.1837461

Ramakoti B, Dhanagopal H, Deepa K et al (2019) Solvent fractionation of organosolv lignin to improve lignin homogeneity: structural characterization. Bioresour Technol Rep 7:100293

Ruiz HA, Conrad M, Sun S-N et al (2020) Engineering aspects of hydrothermal pretreatment: from batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour Technol 299:122685

Saini JK, Saini R, Tewari L (2015) Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. 3 Biotech 5:337–353

Serna-Loaiza S, García-Velásquez CA, Cardona CA (2019) Strategy for the selection of the minimum processing scale for the economic feasibility of biorefineries. Biofuels Bioprod Biorefining 13:107–119

Sluiter A, Hames B, Ruiz R et al (2008) Determination of structural carbohydrates and lignin in biomass. Lab Anal Proced 1617:1–16

Sun Z, Fridrich B, de Santi A et al (2018) Bright side of lignin depolymerization: toward new platform chemicals. Chem Rev 118:614–678

Toledano A, Serrano L, Labidi J et al (2013) Heterogeneously catalysed mild hydrogenolytic depolymerisation of lignin under microwave irradiation with hydrogen-donating solvents. ChemCatChem 5:977–985

Tran UPN, Phan DD, Tran ATT et al (2015) Sodium bicarbonate pretreatment on rice straw for bioethanol production and utilizing the waste water of this process to absorb CO2 in biogas. Sci Technol Dev J 18:96–107

Tran UPN, Van Vu KL, Nguyen QD et al (2013) Energy balance of small-scale biorefinery system. Environ Sci 26:489–496

Ungerman O, Dedkova J, Gurinova K (2018) The impact of marketing innovation on the competitiveness of enterprises in the context of industry 4.0. J Compet 10:132

Vu LVK, Tran PNU, Phan DT et al (2013) Agricultural residues as alternative supplemental nutrients for Bioethanol fermentation process from rice straw. J Sci Technol Vietnam B 5:32–36

Xia Q, Liu Y, Meng J et al (2018) Multiple hydrogen bond coordination in three-constituent deep eutectic solvents enhances lignin fractionation from biomass. Green Chem 20(12):2711–2721. https://doi.org/10.1039/C8GC00900G

Zhang C (2020) Lignocellulosic ethanol: technology and economics. In: Alcohol fuels-current Technol Futur Prospect 1–21. https://doi.org/10.5772/intechopen.86701

Acknowledgements

This research is funded by Vietnam National University under Grant Number B2019-20-11. We acknowledge the support of time and facilities from Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for this study.

Author information

Authors and Affiliations

Contributions

Conceptualization, formal analysis, investigation and writing: TML, Writing and investigation: UPNT; Writing—review and editing, investigation: YHPD; investigation and writing: QDN; supervision, methodology, and conceptualization: VTT; writing, methodology, conceptualization: PTM; Funding acquisition, supervision, methodology, and conceptualization PKL.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Affiliation information of all the authors were updated.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Le, T.M., Tran, U.P.N., Duong, Y.H.P. et al. Sustainable bioethanol and value-added chemicals production from paddy residues at pilot scale. Clean Techn Environ Policy 24, 185–197 (2022). https://doi.org/10.1007/s10098-021-02097-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02097-w