Abstract

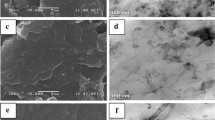

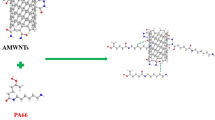

Nanocomposites of polyamide 6 (PA6)–poly(methyl methacrylate) (PMMA)–functionalized single-wall carbon nanotubes (f-SWCNTs) with hydroxyl (SWCNTOH) and carboxylic acid (SWCNTCOOH) in weight ratios of 79.5–19.5–1, 49.5–49.5–1, and 19.5–79.5–1 were fabricated and investigated in terms of morphology, mechanical and XRD studies. Blends of 80–20, 50–50, and 20–80 weight ratios of PA6–PMMA have functioned as references. The scanning electron microscopy images of nanocomposites showed a relatively uniform dispersion of PMMA domains as co-continuous phase morphology in the continuous phase of PA6 compared to their respective blends. The f-SWCNTs acted as functional group-dependent compatibilizers for the PA6–PMMA blend system. Compatibilization of PA6-PMMA blends was higher in the presence of functionalized SWCNTs. XRD analysis indicated that the αI and αII phases of the PA6 were dependent on the weight ratio of the PA6 and PMMA and the nature of the f-SWCNTs. The PMMA-rich blends and nanocomposites exhibited the rich αI phase. The melt strength of the nanocomposites was higher compared to that of the PA6–PMMA blends. All the nanocomposites exhibited higher tensile strength than their corresponding blends. Tensile modulus increased with increasing weight percent of PMMA in blends (from 810 to 1135 MPa) and in nanocomposites (from 854 to 1298 MPa). PA6–PMMA–SWCNTOH19.5–79.5–1 nanocomposites exhibited higher tensile modulus (1298 MPa) compared to all the blends and PA6–PMMA–SWCNTCOOH nanocomposites.

Similar content being viewed by others

References

Spitalsky Z, Tasis D, Papagelis K, Galiotis C (2010) Carbon nanotube–polymer composites: chemistry, processing, mechanical and electrical properties. Prog Polym Sci 35:357–401

Park M, Yoon S, Park J, Park NH, Ju SY (2020) Flavin mononucleotide-mediated formation of highly electrically conductive hierarchical monoclinic multiwalled carbon nanotube-polyamide 6 nanocomposites. ACS Nano 14:10655–10665

Al-Osaimi J, Al-Hosiny N, Abdallah S, Badawi A (2014) Characterization of optical, thermal and electrical properties of SWCNTs/PMMA nanocomposite films. Iran Polym J 23:437–443

Prashantha K, Schmitt H, Lacrampe MF, Krawczak P (2011) Mechanical behaviour and essential work of fracture of halloysite nanotubes filled polyamide 6 nanocomposites. Compos Sci Technol 71:1859–1866

Sahoo NG, Rana S, Cho JW, Li L, Chan SH (2010) Polymer nanocomposites based on functionalized carbon nanotubes. Prog Polym Sci 35:837–867

Ali NA, Hussein SI, Asafa TB, Abd-Elnaiem AM (2020) Mechanical properties and electrical conductivity of poly(methyl methacrylate)/multi-walled carbon nanotubes composites. Iran J Sci Technol Trans Sci 44:1567–1576

Ghanta TS, Aparna S, Verma N, Purnima D (2020) Review on nano- and microfiller-based polyamide 6 hybrid composite: effect on mechanical properties and morphology. Polym Eng Sci 60:1717–1759

Potschke P, Bhattacharyya AR, Janke A (2004) Melt mixing of polycarbonate with multiwalled carbon nanotubes: microscopic studies on the state of dispersion. Eur Polym J 40:137–148

Sathyanarayana S, Olowojoba G, Weiss P, Caglar B, Pataki B, Mikonsaari I, Hubner C, Henning F (2013) Compounding of MWCNTs with PS in a twin-screw extruder with varying process parameters: morphology, interfacial behavior, thermal stability, rheology, and volume resistivity. Macromol Mater Eng 298:89–105

Saeed K, Park SY (2011) Multiwalled-carbon nanotubes/poly(butylene terephthalate) nanofibres: morphological, mechanical and thermal properties. Iran Polym J 20:795–801

Lau KT (2003) Interfacial bonding characteristics of nanotube/polymer composites. Chem Phys Lett 370:399–405

Qian D, Liu WK, Ruoff RS (2003) Load transfer mechanism in carbon nanotube ropes. Compos Sci Technol 63:1561–1569

Barrau S, Demont P, Perez E, Peigney A, Laurent C, Lacabanne C (2003) Effect of palmitic acid on the electrical conductivity of carbon nanotubes-epoxy resin composites. Macromolecules 36:9678–9680

Xia H, Wang Q, Qiu G (2003) Polymer-encapsulated carbon nanotubes prepared through ultrasonically initiated in situ emulsion polymerization. Chem Mater 15:3879–3886

Liu T, Phang IY, Shen L, Chow SY, Zhang WD (2004) Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 37:7214–7222

Velasco C, Martinez SAL, Fisher HFT, Ruoff R, Castano VM (2003) Improvement of thermal and mechanical properties of carbon nanotube composites through chemical functionalization. Chem Mater 15:4470–4475

Raji M, Qaiss AE, Bouhfid R (2020) Effects of bleaching and functionalization of kaolinite on the mechanical and thermal properties of polyamide 6 nanocomposites. RSC Adv 10:4916–4926

Eskandari M, Hosseini SH, Adeli M, Pourjavadi A (2014) Polymer-functionalized carbon nanotubes in cancer therapy: a review. Iran Polym J 23:387–403

Bhattacharyya AR, Potschke P, Haussler L, Fischer D (2005) Reactive compatibilization of melt mixed PA6/SWNT composites: mechanical properties and morphology. Macromol Chem Phys 206:2084–2095

Bhattacharyya AR, Potschke P, Abdel-Goad M, Fischer D (2004) Effect of encapsulated SWNT on the mechanical properties of melt mixedPA12/SWNT composites. Chem Phys Lett 392:28–33

Ajori S, Parsapour H, Ansari R (2019) Structural properties and buckling behavior of non-covalently functionalized single- and double-walled carbon nanotubes with pyrene-linked polyamide in aqueous environment using molecular dynamics simulations. J Phys Chem Solids 131:79–85

Mitchell CA, Bahr JL, Arepalli S, Tour JM, Krishnamoorti R (2002) Dispersion of functionalized carbon nanotubes in polystyrene. Macromolecules 35:8825–8830

Gojny FH, Nastalczyk J, Roslaniec Z, Schulte K (2003) Surface modified multi-walled carbon nanotubes in CNT/epoxy-composites. Chem Phys Lett 370:820–824

Lee SH, Cho E, Jeon SH, Youn JR (2007) Rheological and electrical properties of polypropylene composites containing functionalized multi-walled carbon nanotubes and compatibilizers. Carbon 45:2810–2822

Pan YZ, Li L, Chan SH, Zhao JH (2010) Correlation between dispersion state and electrical conductivity of MWCNTs/PP composites prepared by melt blending. Compos Part A Appl S 41:419–426

Jin SH, Kang CH, Yoon KH, Bang DS, Park YB (2008) Effect of compatibilizer on morphology, thermal, and rheological properties of polypropylene/functionalized multi-walled carbon nanotubes composite. J Appl Poly Sci 111:1028–1033

Wu DF, Zhang YS, Zhang M, Yu W (2009) Selective localization of multiwalled carbon nanotubes in poly(ε-caprolactone)/polylactide blend. Biomacromol 10:417–424

Chen CC, White JL (1993) Compatibilizing agents in polymer blends: interfacial tension, phase morphology, and mechanical properties. Polym Eng Sci 33:923–930

Majumdar B, Keskkula H, Paul DR (1994) Mechanical behavior and morphology of toughened aliphatic polyamides. Polymer 35:1399–1408

Macosko CW, Guegan P, Khandpur AK, Nakayama A, Marechal P, Inoue T (1996) Compatibilizers for melt blending: premade block copolymers. Macromolecules 29:5590–5598

Harrats C, Dedecker K, Groeninckx G, Jerome R (2003) Reactively and physically compatibilized immiscible polymer blends: stability of the copolymer at the interface. Macromol Symp 198:183–196

Motahari S, Kafashi B, Taranehjoo S, Sarrafi M (2012) PMMA/polyamide6/silica ternary nanocomposites: investigation of dynamic rheology, crystallization and blend phase morphology. Can J Civ Eng 3:80–93

Wang HL, Shi TJ, Yang SZ, Zhai LF, Hang GP (2006) Crystallization behavior of PA66/SiO2 organic-inorganic hybrid material. J Appl Polym Sci 101:810–817

Venkatesh GM, Gilbert RD, Fornes RE (1985) Fourier transform infra-red spectroscopy of nylon-6 blends: binary blends with poly(methyl methacrylate) and ethylene vinyl ester/alcohol copolymer. Polymer 26:45–49

Carone E, Felisberti MI, Nunes SP (1998) Blends of poly(methyl methacrylate) and polyamides. J Mater Sci 33:3729–3735

Xu Z, Zhao C, Gu A, Fang Z, Tong L (2008) Effect of morphology on the electric conductivity of binary polymer blends filled with carbon black. J Appl Polym Sci 106:2008–2017

Wu T, Xie T, Yang G (2009) Synthesis and properties of monomer casting polyamide 6/poly(methyl methacrylate) blends. J Appl Polym Sci 111:101–107

Khaydarov AA, Kazlauciunas A, Mounterey PE, Perrier S (2010) Investigation of polymer blends of polyamide-6 and poly(methyl methacrylate) synthesized by RAFT polymerization. Polym Bull 66:1089–1098

Mallick S, Khatua BB (2011) Effect of nanoclay on the morphology and properties of nylon 6 and poly(methyl methacrylate) (PMMA) blends. J Macromol Sci Phys 50:1791–1809

Madhukar K, Sainath AVS, Bikshamaiah N, Srinivas Y, Babu NM, Ashok B, Kumar DS, Rao BS (2014) Thermal properties of single walled carbon nanotubes composites of polyamide 6/poly(methyl methacrylate) blend system. J Therm Anal Calorim 115:345–354

Madhukar K, Sainath AVS, Rao BS, Kumar DS, Bikshamaiah N, Srinivas Y, Babu NM, Ashok B (2013) Role of carboxylic acid functionalized single walled carbon nanotubes in polyamide 6/poly(methyl methacrylate) blend. Polym Eng Sci 53:397–402

Sainath AVS, Inoue T, Yonetake K, Koyama K (2001) Thermal behavior of polyacryloyloxybenzoic/nylon 6 blends. Polymer 42:9859–9862

Dixit M, Mathur V, Gupta S, Baboo M, Sharma K, Saxena NS (2009) Morphology, miscibility and mechanical properties of PMMA/PC blends. Phase Transit 82:866–878

Acknowledgements

Authors thank Dr. Smita Mohanty, Ms. Mousam Choudhury, LARPM-CIPET, Bhubaneswar and Dr. P. Uday Kumar, NIN, Hyderabad, India for their support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bikshamaiah, N., Babu, N.M., Kumar, D.S. et al. Carbon nanotube functional group-dependent compatibilization of polyamide 6 and poly(methyl methacrylate) nanocomposites. Iran Polym J 30, 789–799 (2021). https://doi.org/10.1007/s13726-021-00930-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00930-z