Abstract

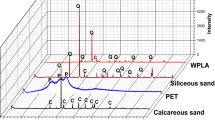

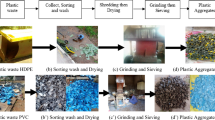

The use of waste plastic as aggregate in cement composites can solve the problem of the disposal of waste plastics in a sustainable way, and it reduces the need for extracting traditional materials like sand and gravel, which causes erosion and environmental degradation. The reaction of plastics with certain oxidizing chemicals is believed to result in chemical or electrostatic bonding between the plastic surface and the cement matrix. The present study investigates the effect of pre-treating plastic aggregates (with sodium hydroxide and sodium hypochlorite) on certain engineering properties of cement mortars. Five types of recycled plastics are used as partial sand replacements. Two replacement levels (5 and 15% by volume of sand) and two methods of chemical treatment are investigated. The results showed a decline in the properties of mortars made with chemically treated plastic aggregates: the addition of treated plastic aggregates makes the matrix porous, thereby degrading the mechanical properties. This behaviour intensifies with increasing plastic dosage. The polyoxymethylene (POM) and acrylonitrile butadiene styrene (ABS) plastic mortars performed best, while the polyethylene terephthalate (PET) mortars achieved poor results. Water-rinsing the treated aggregates removed reactive species from the plastic surface, and neutralized the matrix alkalinity resulting in comparatively less porous structures.

Similar content being viewed by others

Data availability

All data, models, and code generated or used during the study appear in the submitted article.

References

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3(7):e1700782. https://doi.org/10.1126/sciadv.1700782

World Economic Forum (2016) The new plastics economy: Rethinking the future of plastics. The Ellen MacArthur Foundation. https://www.ellenmacarthurfoundation.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics. Accessed 4 September 2020

Plastics Insight (2020) Resin prices. See https://www.plasticsinsight.com/resin-intelligence/resinprices/. Accessed 02 Feb 2020

Kaur G, Pavia S (2020) Durability of mortars made with recycled plastic aggregates: Resistance to frost action, salt crystallization and cyclic thermal/moisture variations. J Mater in Civil Eng 33(2):04020450. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003566

Gu L, Ozbakkaloglu T (2016) Use of recycled plastics in concrete: a critical review. Waste Manage 51:19–42. https://doi.org/10.1016/j.wasman.2016.03.005

Singh N, Hui D, Singh R et al (2017) Recycling of plastic solid waste: a state of art review and future applications. Compos B 115:409–422. https://doi.org/10.1016/j.compositesb.2016.09.013

Awoyera PO, Adesina A (2020) Plastic wastes to construction products: Status, limitations and future perspective. Case Stud Constr Mater 12:e00330. https://doi.org/10.1016/j.cscm.2020.e00330

Pavlík Z, Pavlíková M and Záleská M (2019) Properties of concrete with plastic polypropylene aggregates, in use of recycled plastics in eco-efficient concrete. Woodhead publishing series in civil and structural engineering, pp. 189–213.

Naik TR, Singh SS, Huber CO et al (1996) Use of post-consumer waste plastics in cement-based composites. Cem Concr Res 26:1489–1492. https://doi.org/10.1016/0008-8846(96)00135-4

Angel FCD and Ruiz JLV (2012) Manufacturing light concrete with PET aggregate. Int Sch Res Notices 2012:287323. https://doi.org/10.5402/2012/287323

Thorneycroft J, Orr J, Savoikar P et al (2018) Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr Build Mater 161:63–69. https://doi.org/10.1016/j.conbuildmat.2017.11.127

Sadrmomtazi A, Milehsara SD, Omran OL et al (2016) The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of self-compacting concrete. J Clean Prod 112:2363–2373. https://doi.org/10.1016/j.jclepro.2015.09.107

Saikia N, Brito JD (2012) Waste polyethylene terephthalate as an aggregate in concrete. Mater Res 16:341–350. https://doi.org/10.1590/S1516-14392013005000017

Babafemi AJ, Šavija B, Paul SC (2018) Engineering properties of concrete with waste recycled plastic: a review. Sustainability 10(11):3875. https://doi.org/10.3390/su10113875

Vaillancourt CJ, Sorelli L (2018) Characterization of concrete composites with recycled plastic aggregates from postconsumer material streams. Constr Build Mater 182:561–572. https://doi.org/10.1016/j.conbuildmat.2018.06.083

Mohammed AA, Mohammed II, Mohammed SA (2019) Some properties of concrete with plastic aggregate derived from shredded PVC sheets. Constr Build Mater 201:232–245. https://doi.org/10.1016/j.conbuildmat.2018.12.145

Almeshal I, Tayeha BA, Alyousef R et al (2020) Eco-friendly concrete containing recycled plastic as partial replacement for sand. J Mater Res Technol 9(3):4631–4643. https://doi.org/10.1016/j.jmrt.2020.02.090

Iucolano F, Liguoria B, Caputo D et al (2013) Recycled plastic aggregate in mortars composition: effect on physical and mechanical properties. Mater Des 52:916–922. https://doi.org/10.1016/j.matdes.2013.06.025

Choi YW, Moon DJ, Chung JS et al (2005) Effects of waste PET bottles aggregate on the properties of concrete. Cem Concr Res 35:776–781. https://doi.org/10.1016/j.cemconres.2004.05.014

Choi YW, Moon DJ, Kim YJ et al (2009) Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr Build Mater 23:2829–2835. https://doi.org/10.1016/j.conbuildmat.2009.02.036

Coppola B, Courard L, Michel F et al (2018) Hygro-thermal and durability properties of a lightweight mortar made with foamed plastic waste aggregates. Constr Build Mater 170:200–206. https://doi.org/10.1016/j.conbuildmat.2018.03.083

Badache A, Benosman AS, Senhadji Y et al (2018) Thermo-physical and mechanical characteristics of sand-based lightweight composite mortars with recycled high-density polyethylene (HDPE). Constr Build Mater 163:40–52. https://doi.org/10.1016/j.conbuildmat.2017.12.069

Marzouk OY, Dheilly RM, Queneudec M (2007) Valorisation of post-consumer plastic waste in cementitious concrete composites. Waste Manage 27:310–318. https://doi.org/10.1016/j.wasman.2006.03.012

Saikia N, Brito JD (2012) Use of plastic waste as aggregate in cement mortar and concrete preparation: a review. Constr Build Mater 34:385–401. https://doi.org/10.1016/j.conbuildmat.2012.02.066

Hannawi K, Kamali BS, Prince W (2010) Physical and mechanical properties of mortars containing PET and PC waste aggregates. Waste Manage 30:2312–2320. https://doi.org/10.1016/j.wasman.2010.03.028

Albano C, Camacho N, Hernandez M et al (2009) Influence of content and particle size of PET waste bottles on concrete behaviour at different w/ c ratios. Waste Manage 29:707–716. https://doi.org/10.1016/j.wasman.2009.05.007

Junco C, Gadea J, Rodríguez A et al (2012) Durability of lightweight masonry mortars made with white recycled polyurethane foam. Cem Concr Compos 34:1174–1179. https://doi.org/10.1016/j.cemconcomp.2012.07.006

Wang R, Meyer C (2012) Performance of cement mortar made with recycled high impact polystyrene. Cem Concr Compos 34:975–981. https://doi.org/10.1016/j.cemconcomp.2012.06.014

Silva AMD, Brito JD, Veiga R (2014) Incorporation of fine plastic aggregates in rendering mortars. Constr Build Mater 71:226–236. https://doi.org/10.1016/j.conbuildmat.2014.08.026

Akcaozoglu S, Atis CD, Akcaozoglu K (2010) An investigation on the use of shredded pet waste bottles as aggregate in lightweight concrete. Waste Manage 32:285–290. https://doi.org/10.1016/j.wasman.2009.09.033

Frigione M (2010) Recycling of PET bottles as fine aggregate in concrete. Waste Manage 30:1101–1106

Makri C, Hahladakis JN, Gidarako E (2019) Use and assessment of “e-plastics” as recycled aggregates in cement mortar. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2019.120776

Kaur G, Pavia S (2020) Physical properties and microstructure of plastic aggregate mortars made with acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), polyoxymethylene (POM) and ABS/PC blend waste. J Build Eng 31:101341. https://doi.org/10.1016/j.jobe.2020.101341

Siddique R, Khatib J, Kaur I (2008) Use of recycled plastic in concrete: a review. Waste Manage 28:1835–1852. https://doi.org/10.1016/j.wasman.2007.09.011

Liu F, Yan Y, Li L et al (2015) Performance of recycled plastic-based concrete. J Mater Civ Eng 27:A4014004. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000989

Lee ZH, Paul SC, Kong SY et al (2019) Modification of waste aggregate PET for improving the concrete properties Adv. Civ Eng 2019:6942052. https://doi.org/10.1155/2019/6942052

Purnomo H, Pamudji G, Satim M (2017) Influence of uncoated and coated plastic waste coarse aggregates to concrete compressive strength. MATEC Web Conf 101:01016. https://doi.org/10.1051/matecconf/201710101016

EN (European Standards) (1999) EN 1015–1: Methods of test for mortar for masonry: Determination of particle size distribution (by sieve analysis). Brussels, Belgium.

EN (European Standards) (2005) EN 196–1: Methods of testing cement—Part 1: Determination of strength. Brussels, Belgium.

EN (European Standards) (1999) EN 1015–2: Methods of test for mortar for masonry- Part 2: Bulk sampling of mortars and preparation of test mortars. Belgium, Brussels

RILEM (1980) RILEM TC 25-PEM: Recommended tests to measure the deterioration of stone and to assess the effectiveness of treatment methods. Materiaux et Constructions, Paris

EN (European Standards) (1999) EN 1925: Natural stone test methods: Determination of water absorption coefficient by capillarity. Brussels, Belgium.

EN (European Standards) (1999) EN 1015–11: Methods of test for mortar for masonry: Determination of flexural and compressive strength of hardened mortar. Belgium, Brussels

IS (Indian Standards) (1999) IS 5816: Splitting tensile strength of concrete- method of test. New Delhi, India

RILEM LC2 (1978) RILEM 632 recommendations: Functional classification of lightweight concrete.

Ismail ZZ, Al-Hashmi EA (2008) Use of plastic waste in concrete mixture as aggregate replacement. Waste Manage 28:2041–2047. https://doi.org/10.1016/j.wasman.2007.08.023

Acknowledgements

The authors gratefully acknowledge the help provided by the Chief Technician and the technical staff in the Department of Civil Engineering, Trinity College Dublin, in particular, Mr. Mark Gilligan. The authors also thank the Thapar Institute of Engineering and Technology, Patiala for their financial support. The authors wish to thank N. Skeffington, Wellman Int. Ltd. and G. McGovern, Polyfab Ltd.

Funding

This research received financial support from the Thapar Institute of Engineering and Technology, Patiala, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kaur, G., Pavia, S. Chemically treated plastic aggregates for eco-friendly cement mortars. J Mater Cycles Waste Manag 23, 1531–1543 (2021). https://doi.org/10.1007/s10163-021-01235-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01235-2