Abstract

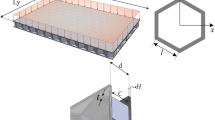

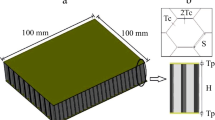

Sandwich structure T-joints are increasingly broadly applied in aviation and aerospace industries due to the need for lightweight design. This paper deals with the lightweight optimization of a typical adhesively bonded Nomex honeycomb-core sandwich T-joint in side bending load, considering the strength constraints. The optimization problem, with discrete and continuous design variables, is a compound optimization problem involving size optimization for the whole structure and stacking sequence optimization for multiple variable-thickness composite laminates. A self-adjusted parametric modeling with user-defined suppression process is proposed. An integrated combination of progressive damage model methodology, self-adjusted parametric modeling with user-defined suppression process and multi-island genetic algorithm is applied for the optimization problem. The optimization result showed 30.75% weight reduction compared to the original T-joint configuration. On the basis of history data, we investigate the correlations between design variables and concerned constraint variables.

Similar content being viewed by others

References

Bozhevolnaya, E., Lyckegaard, A., Thomsen, O.T.: Novel design of foam core junctions in sandwich panels. Compos. B. Eng. 39, 185–190 (2008)

Stickler, P.B., Ramulu, M.: Investigation of mechanical behavior of transverse stitched T-joints with PR520 resin in flexure and tension. Compos. Struct. 52, 307–314 (2001)

Guo, S., Morishima, R.: Numerical analysis and experiment of composite sandwich T-joints subjected to pulling load. Compos. Struct. 94, 229–238 (2012)

Khalili, S.M.R., Ghaznavi, A.: Numerical analysis of adhesively bonded T-joints with structural sandwiches and study of design parameters. Int. J. Adhes. Adhes. 31, 347–356 (2011)

Khalili, S.M.R., Ghaznavi, A.: Behavior and failure modes of sandwich T-joint using cohesive zone material model and contact elements. Appl. Compos. Mater. 20, 41–54 (2013)

Khosravani, M.R.: Influences of defects on the performance of adhesively bonded sandwich joints. Key. Eng. Mater. 89, 45–50 (2018)

Khosravani, M.R., Anders, D., Weinberg, K.: Influence of strain rate on fracture behavior of sandwich composite T-joints. Eur. J. Mech. A. Solids (2019). https://doi.org/10.1016/j.euromechsol.2019.103821

Sun., C.T.: Failure modes and load transfer in sandwich T-joints. J. Sandw. Struct. Mater. 2, 225–245 (2000)

Saeid, A.A., Donaldson, S.L.: Experimental and finite element investigations of damage resistance in biomimetic composite sandwich T-joints. Materials. 9, 510 (2016)

Ghiasi, H., Pasini, D., Lessard, L.: Optimum stacking sequence design of composite materials Part I: Constant stiffness design. Compos. Struct. 90, 1–11 (2009)

Ghiasi, H., Fayazbakhsh, K., Pasini, D., et al.: Optimum stacking sequence design of composite materials Part II: Variable stiffness design. Compos. Struct. 93, 1–13 (2011)

Naik, G.N., Gopalakrishnan, S., Ganguli, R.: Design optimization of composites using genetic algorithms and failure mechanism based failure criterion. Compos. Struct. 83, 354–367 (2008)

Zhu, X., He, R., Lu, X., et al.: A optimization technique for the composite strut using genetic algorithms. Mater. Design. 65, 482–488 (2015)

Yang, J., Song, B., Zhong, X., et al.: Optimal design of blended composite laminate structures using ply drop sequence. Compos. Struct. 135, 30–37 (2016)

Lund, E., Stegmann, J.: On structural optimization of composite shell structures using a discrete constitutive parametrization. Wind Energy. 8, 109–124 (2005)

Matsuzaki, R., Todoroki, A.: Stacking-sequence optimization using fractal branch-and-bound method for unsymmetrical laminates. Compos. Struct. 78, 537–550 (2007)

Zhao, J., Fan, X., Sun, Q.: Stacking sequence optimization of composite laminates for maximum buckling load using permutation search algorithm. Compos. Struct. 121, 225–236 (2015)

Albazzan, M.A., Harik, R., Tatting, B.F., et al.: Efficient design optimization of nonconventional laminated composites using lamination parameters: A state of the art. Compos. Struct. 209, 362–374 (2019)

Niu, Y., Xu, X., Guo, S.: Structural optimization design of typical adhesive bonded sandwich T-joints based on progressive damage analysis and multi-island genetic algorithm. J. Sandwich Struct. Mater. (2020). https://doi.org/10.1177/1099636220962278

Holland, J.H.: Genetic Algorithms and the Optimal Allocation of Trials. SIAM. J. Comput. 2, 88–105 (1973)

Miki, M., Hiroyasu, T., Kaneko, M., et al.: A parallel genetic algorithm with distributed environment scheme. Proceedings of International Conference on Systems, Man, and Cybernetics. 1, 695–700 (1999). https://doi.org/10.1109/ICSMC.1999.814176

Azzi, V.D., Tsai, S.W.: Anisotropic strength of composites. Exp. Mech. 5, 283–288 (1965)

Tsai, S.W., Wu, E.M.: A general theory of strength for anisotropic materials. J. Compos. Mater. 5, 58–80 (1971)

Hoffman, O.: The brittle strength of orthotropic materials. J. Compos. Mater. 1, 200–206 (1967)

Hashin, Z.: Failure criteria for unidirectional fiber composites. J. Appl. Mech. 47, 329–334 (1980)

Hashin, Z., Rotem, A.: A fatigue failure criterion for fiber reinforced materials. J. Compos. Mater. 7, 448–464 (1973)

Puck, A., Schürmann, H.: Failure analysis of FRP laminates by means of physically based phenomenological models. Compos. Sci. Technol. 58, 1045–1067 (1998)

Puck, A., Schürmann, H.: Failure analysis of FRP laminates by means of physically based phenomenological models. Compos. Sci. Technol. 62, 1633–1662 (2002)

Cuntze, R.G., Freund, A.: The predictive capability of failure mode concept-based strength criteria for multidirectional laminates. Part A. Compos. Sci. Technol. 64, 343–377 (2004)

Cuntze, R.G.: The predictive capability of failure mode concept-based strength criteria for multidirectional laminates. Part B. Compos. Sci. Technol. 63, 487–516 (2004)

Cuntze, R.: The predictive capability of failure mode concept-based strength conditions for laminates composed of unidirectional laminae under static triaxial stress states. J. Compos. Mater. 46(19–20), 2563–2594 (2012)

Labeas, G.N., Belesis, S.D., Diamantakos, I., et al.: Adaptative progressive damage modeling for large-scale composite structures. Int. J. Damage. Mech. 21, 441–462 (2012)

Hou, J.P., Petrinic, N., Ruiz, C.: A delamination criterion for laminated composites under low-velocity impact. Compos. Sci. Technol. 61, 2069–2074 (2001)

Hou, J.P., Petrinic, N., Ruiz, C., et al.: Prediction of impact damage in composite plates. Compos. Sci. Technol. 60, 273–281 (2000)

Camanho, P.P.: A progressive damage model for mechanically fastened joints in composite laminates. J. Compos. Mater. 33, 2248–2280 (1999)

Camanho, P.P., Davila, C.G.: Mixed-mode decohesion finite elements for the simulation of delamination in composite materials. NASA/TM-2002–211737, pp. 1–37 (2002)

Sane, A.U., Padole, P.M., Manjunatha, C.M., et al.: Mixed mode cohesive zone modeling and analysis of adhesively bonded composite T-joint under pull-out load. J. Braz. Soc. Mech. Sci. 40, 167 (2018)

Xu, Y.Y., Cheng, X.Q., Zhang, J.K., Li, Z.N.: Study on composite honeycomb sandwich structure formed t-joints under tensile load. Engineering Mechanics. 32, 243–256 (2015). https://doi.org/10.6052/j.issn.1000-4750.2013.12.1236

Stein, N., Rosendahl, P.L., Becker, W.: Modelling load transfer and mixed-mode fracture of ductile adhesive composite joints. Int. J. Adhes. Adhes. 82, 299–310 (2018)

Gleich, D.M., Van Tooren, M.J.L., Beukers, A.: Analysis and evaluation of bondline thickness effects on failure load in adhesively bonded structures. J. Adhes. Sci. Technol. 15, 1091–1101 (2001)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Niu, Y., Xu, X. & Guo, S. Structural Optimization Design of a Typical Adhesive Bonded Honeycomb-Core Sandwich T-joint in Side Bending Using Multi-Island Genetic Algorithm. Appl Compos Mater 28, 1039–1066 (2021). https://doi.org/10.1007/s10443-021-09882-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09882-2