Abstract

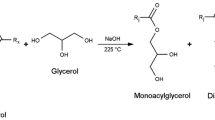

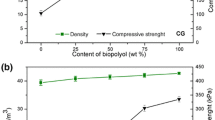

In this study, the synthesis of biopolyols derived from castor oil and glycerol was performed by enzymatic glycerolysis in a solvent-free system applying the lipases: Novozym® 435 (N435), from Candida antarctica fraction B, immobilized on macroporous anionic resin, and Eversa® Transform 2.0, a soluble formulation from Thermomyces lanuginosus. The biopolyols presented different conversion into mono- and diacylglycerol (MAG and DAG) owing to regioselectivity of the lipases. The resulting biopolyols were employed for the synthesis of polyurethane foams using different amounts of chemical blowing agent (water). The NCO source employed was polymeric methylene diphenyl diisocyanate (pMDI). The foams were compared, and the results showed that the PU foams obtained by using the biopolyol from lipase N435 presented uniform pore size and more desirable mechanical characteristics. Although this has arisen, the results obtained by using the lipase Eversa® Transform 2.0 showed the possibility of applying a low-cost enzyme to obtain biopolyols and foams, and there may be a possibility of competition with chemical catalysts.

Similar content being viewed by others

References

Ghasemlou M, Daver F, Ivanova EP, Adhikari B (2019) Bio-based routes to synthesize cyclic carbonates and polyamines precursors of non-isocyanate polyurethanes: a review. Eur Polym J 118:668–684. https://doi.org/10.1016/j.eurpolymj.2019.06.032

Sawpan MA (2018) Polyurethanes from vegetable oils and applications: a review. J Polym Res 25:1–15. https://doi.org/10.1007/s10965-018-1578-3

Moustafa H, Youssef AM, Darwish NA, Abou-kandil AI (2019) Eco-friendly polymer composites for green packaging: future vision and challenges. Composites B 172:16–25. https://doi.org/10.1016/j.compositesb.2019.05.048

Tenorio-alfonso A, Sánchez MC, Franco JM (2019) Synthesis and mechanical properties of bio-sourced polyurethane adhesives obtained from castor oil and MDI-modified cellulose acetate: influence of cellulose acetate modification. Int J Adhes Adhes. https://doi.org/10.1016/j.ijadhadh.2019.102404

Noreen A, Zia KM, Zuber M et al (2016) Bio-based polyurethane: an efficient and environment friendly coating systems: a review. Prog Org Coat 91:25–32. https://doi.org/10.1016/j.porgcoat.2015.11.018

Bresolin D, Mazurek V, Valério A et al (2018) Poly (urea-urethane) nanoparticles using mono-and diacylglycerol from glycerolysis of castor oil as biopolyol and stabilizer. Eur Polym J 108:529–535. https://doi.org/10.1016/j.eurpolymj.2018.09.044

Bresolin D, Valério A, de Oliveira D et al (2018) Polyurethane foams based on biopolyols from castor oil and glycerol. J Polym Environ. https://doi.org/10.1007/s10924-017-1138-7

Furtwengler P, Avérous L (2018) Renewable polyols for advanced polyurethane foams from diverse biomass resources. Polym Chem. https://doi.org/10.1039/c8py00827b

Liu F, Chen S (2021) The preparation and characterization of polyurethane foam with coconut oil polyol and rapeseed oil polyol. J Polym Environ. https://doi.org/10.1007/s10924-020-02008-y

Zhang C, Garrison TF, Madbouly SA, Kessler MR (2017) Recent advances in vegetable oil-based polymers and their composites. Prog Polym Sci 71:91–143. https://doi.org/10.1016/j.progpolymsci.2016.12.009

Abdul Halim KA, Soloi S, Majid RA (2015) Synthesis of palm oil based polyol via glycerolysis and transamidation reactions for polyurethane foam production. Appl Mech Mater 735:226–229. https://doi.org/10.4028/www.scientific.net/AMM.735.226

Tanaka R, Hirose S, Hatakeyama H (2008) Preparation and characterization of polyurethane foams using a palm oil-based polyol. Bioresour Technol 99:3810–3816. https://doi.org/10.1016/j.biortech.2007.07.007

Destaillats F, Cruz-Hernandez C, Nagy K, Dionisi F (2010) Identification of monoacylglycerol regio-isomers by gas chromatography-mass spectrometry. J Chromatogr A 1217:1543–1548. https://doi.org/10.1016/j.chroma.2010.01.016

Meiorin C, Calvo-Correas T, Mosiewicki MA et al (2020) Comparative effects of two different crosslinkers on the properties of vegetable oil-based polyurethanes. J Appl Polym Sci 137:1–12. https://doi.org/10.1002/app.48741

Mamtani K, Shahbaz K, Farid MM (2020) Glycerolysis of free fatty acids: a review. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2020.110501

Zhong N, Li L, Xu X et al (2013) High yield of monoacylglycerols production through low-temperature chemical and enzymatic glycerolysis. Eur J Lipid Sci Technol 115:684–690. https://doi.org/10.1002/ejlt.201200377

Pellis A, Cantone S, Ebert C, Gardossi L (2018) Evolving biocatalysis to meet bioeconomy challenges and opportunities. N Biotechnol 40:154–169. https://doi.org/10.1016/j.nbt.2017.07.005

Bresolin D, Hawerroth B, de Oliveira RC et al (2020) Immobilization of lipase Eversa Transform 2.0 on poly (urea–urethane) nanoparticles obtained using a biopolyol from enzymatic glycerolysis. Bioprocess Biosyst Eng. https://doi.org/10.1007/s00449-020-02324-6

Laguerre M, Nlandu Mputu M, Brïys B et al (2017) Regioselectivity and fatty acid specificity of crude lipase extracts from Pseudozyma tsukubaensis, Geotrichum candidum, and Candida rugosa. Eur J Lipid Sci Technol 119:1–10. https://doi.org/10.1002/ejlt.201600302

da Silva JAP, Cardozo NSM, Petzhold CL (2018) Enzymatic synthesis of andiroba oil based polyol for the production of flexible polyurethane foams. Ind Crops Prod 113:55–63. https://doi.org/10.1016/j.indcrop.2018.01.020

Valério A, Rovani S, Treichel H et al (2010) Optimization of mono and diacylglycerols production from enzymatic glycerolysis in solvent-free systems. Bioprocess Biosyst Eng 33:805–812. https://doi.org/10.1007/s00449-009-0402-1

Facin BR, Valério A, de Oliveira D, Oliveira JV (2020) Developing an immobilized low-cost biocatalyst for FAME synthesis. Biocatal Agric Biotechnol. https://doi.org/10.1016/j.bcab.2020.101752

Li S, Bouzidi L, Narine SS (2017) Polyols from self-metathesis-generated oligomers of soybean oil and their polyurethane foams. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2017.06.003

Ivdre A, Abolins A, Sevastyanova I et al (2020) Rigid polyurethane foams with various isocyanate indices based on polyols from rapeseed oil and pet waste. Polymers 12(738):1–12. https://doi.org/10.3390/polym12040738

Zieleniewska M, Leszczyński MK, Kurańska M et al (2015) Preparation and characterisation of rigid polyurethane foams using a rapeseed oil-based polyol. Ind Crops Prod 74:887–897. https://doi.org/10.1016/j.indcrop.2015.05

Singh I, Samal SK, Mohanty S, Nayak SK (2020) Recent advancement in plant oil derived polyol-based polyurethane foam for future perspective: a review. Eur J Lipid Sci Technol 122:1–23. https://doi.org/10.1002/ejlt.201900225

American Standard Method ASTM D1957-86 (2001) Standard test method for hydroxyl value of fatty oils and acids. West Conshohocken, PA

American Standard Method ASTM D1622 (2004) Standard test method for apparent density of rigid cellular plastics. West Conshohocken, PA

American Standard Method ASTM D1621 (2016) Standard test method for compressive properties of rigid cellular plastics. West Conshohocken, PA

Ortiz C, Ferreira ML, Barbosa O et al (2019) Novozym 435: the “perfect” lipase immobilized biocatalyst? Catal Sci Technol. https://doi.org/10.1039/c9cy00415g

Ferreira-Dias S, Correia AC, Baptista FO, Da Fonseca MMR (2001) Contribution of response surface design to the development of glycerolysis systems catalyzed by commercial immobilized lipases. J Mol Catal B 11:699–711. https://doi.org/10.1016/S1381-1177(00)00079-5

Fernandez-Lafuente R (2010) Lipase from Thermomyces lanuginosus: uses and prospects as an industrial biocatalyst. J Mol Catal B 62:197–212. https://doi.org/10.1016/j.molcatb.2009.11.010

Long Y, An J, Xie X (2020) CO2-releasing blowing agents from modified polyethylenimines slightly consume isocyanate groups while foaming polyurethanes. Arab J Chem 13:3226–3235. https://doi.org/10.1016/j.arabjc.2018.10.007

Kurańska M, Prociak A, Michałowski S, Zawadzińska K (2018) The influence of blowing agents type on foaming process and properties of rigid polyurethane foams. Polimery 63:672–678. https://doi.org/10.14314/polimery.2018.10.2

Thirumal M, Khastgir D, Singhe NK et al (2008) Effect of foam density on the properties of water blown rigid polyurethane foam. J Appl Polym Sci 108:1810–1817. https://doi.org/10.1002/app.27712

Zhang M, June SM, Long TE, Kong J (2016) Principles of step-growth polymerization (polycondensation and polyaddition). In: Polymer science: a comprehensive reference. Elsevier Science, pp 7–47. https://doi.org/10.1016/B978-0-444-53349-4.00131-X

Lim H, Kim EY, Kim BK (2010) Polyurethane foams blown with various types of environmentally friendly blowing agents. Plast Rubber Compos 39:364–369. https://doi.org/10.1179/174328910X12691245469835

Calleros EL, Simonovsky FI, Garty S, Ratner BD (2020) Crosslinked, biodegradable polyurethanes for precision-porous biomaterials: synthesis and properties. J Appl Polym Sci 137:1–16. https://doi.org/10.1002/app.48943

Choe KH, Lee DS, Seo WJ et al (2004) Properties of rigid polyurethane foams with blowing agents and catalysts. Polym J 36:368–373. https://doi.org/10.1295/polymj.36.368

Jia D, Hu J, He J, Yang R (2019) Properties of a novel inherently flame-retardant rigid polyurethane foam composite bearing imide and oxazolidinone. J Appl Polym Sci 136:1–12. https://doi.org/10.1002/app.47943

Rattanapan S, Pasetto P, Pilard J (2016) Preparation and properties of bio-based polyurethane foams from natural rubber and polycaprolactone diol. J Polym Res. https://doi.org/10.1007/s10965-016-1081-7

Tan C, Tirri T, Wilen C-E (2017) Investigation on the influence of chain extenders on the performance of one-component moisture-curable polyurethane adhesives. Polymers 9:184. https://doi.org/10.3390/polym9050184

Stuart BH (2004) Organic molecules. Wiley, Sydney, pp 72–152

Carriço CS, Fraga T, Carvalho VE, Pasa VMD (2017) Polyurethane foams for thermal insulation uses produced from castor oil and crude glycerol biopolyols. Molecules. https://doi.org/10.3390/molecules22071091

Wang C, Zheng Y, Xie Y et al (2015) Synthesis of bio-castor oil polyurethane flexible foams and the influence of biotic component on their performance. J Polym Res. https://doi.org/10.1007/s10965-015-0782-7

Acknowledgements

The authors are thankful to Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq-Process: 142143/2014-6) for its financial support; Novozymes ® for kindly donating the enzymes; Laboratório Central de Microscopia Eletrônica (LCME) of Universidade Federal de Santa Catarina (UFSC) for scanning electron microscopy images; and Campestre for donating the castor oil.

Funding

The work was supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (Grant Nº. 142143/2014-6) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Grant Nº. 88887.318348/2019-00).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bresolin, D., Bolzan, A., Sayer, C. et al. Rigid Polyurethane Foam Obtained from Enzymatic Glycerolysis: Evaluation of the Influence of Lipase on Biopolyol Composition and Polymer Characteristics. J Polym Environ 29, 3900–3908 (2021). https://doi.org/10.1007/s10924-021-02159-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02159-6