Abstract

Reinforced retaining walls are structures constructed horizontally to resist earth pressure by leveraging the frictional force imparted by the backfill. Reinforcements are employed because they exhibit excellent safety and economic efficiency. However, insufficient reinforcement can lead to collapse, and excessive reinforcement reduces economic efficiency. Therefore, it is important to select the appropriate type, length, and spacing of reinforcements. However, in actual sites, although the stress and fracture mechanisms in the straight and curved sections of reinforced soil retaining walls differ, the same amount of reinforcements are typically installed. Such an approach can lead to wall collapse or reduce economic feasibility. Therefore, in this study, the behaviours of straight and curved sections fortified with reinforcements of various lengths (1, 3, 5, and 7 m) are predicted through a three-dimensional numerical analysis. The retaining walls are of the same height, but the reinforcement variations in the aforementioned sections influence the wall behaviour differently. Based on the results, the optimum reinforcement lengths for the straight and curved parts were selected. By installing reinforcements of different lengths in these sections, the maximum reinforcing effect with minimum reinforcement was derived. This study further found that the curved section of the wall required more reinforcements, and the reinforcement lengths for the curved and straight sections should be separately optimized.

Similar content being viewed by others

Introduction

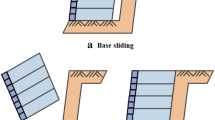

Reinforced retaining walls are horizontally installed structures invented by a French engineer named Vidal. These walls, which include thin galvanised steel plates, geogrids, and geotextiles, resist earth pressure using the frictional resistance imparted by the backfill. The reinforced retaining wall is regarded as a gravity wall fortified with reinforcements constituting a single body and must be appropriately designed to be capable of resisting external forces exerted by the backfill and external loads [2]. The reinforcement must provide stability to the wall to prevent failures, such as those shown in Fig. 1. Two cases of geosynthetic reinforced retaining wall collapse are shown in Fig. 2. As shown in Fig. 2(a), the front section (height: 20 m) of the retaining wall collapses with the soil, destroying the piles supporting the building. Cracks and displacements continued to propagate because of groundwater and surface water infiltration; nevertheless, the collapse occurred due to negligence. The curved front section of the retaining wall bulges and cracks, as shown in Fig. 2b. This was because the retaining wall was constructed without sufficient reinforcement to support the curved segment [10].

Patterns of collapse [2]

Failure case of geosynthetic retaining wall [10]

Evidently, the appropriate selection of retaining wall reinforcement is crucial. The construction of a retaining wall without considering various factors, such as reinforcement type, length, and spacing, leads to collapse or economic loss. In general, the reinforcements should receive sufficient frictional force or passive resistance at the contact surface between the reinforcement and soil. They must also possess sufficient tensile strength, strain capacity, and durability [9]. The recommended maximum and minimum ranges of vertical spacing of reinforcements are 80–100 and 20–30 cm, respectively, and the reinforcement length is calculated using Eq. (1). In this study, depending on the retaining wall conditions, the maximum reinforcement length used was 3 m. To simulate over-reinforcement, four cases (1, 3, 5, and 7 m) were compared and analysed. Based on the comparison, the appropriate reinforcement length was calculated, and various lengths were used for the straight and curved sections of the retaining wall. Hence, this study shows that the maximum reinforcement effect can be derived at a minimum cost by employing different reinforcement lengths for the straight and curved parts.

L: Reinforcement length; H: Height of retaining wall; z: of reinforcement location;

φ: Shearing resistance angle; Ka: Active earth pressure coefficient;

Sv: Vertical offset of reinforcements; FSp: Factor of safety against breaking; φu: (2/3)φ.

Literature review

A retaining wall is a structure that supports steep soil in the transverse direction to prevent collapse; it is mainly built to optimise the use of limited land. In addition to the study of retaining walls, the investigation of the stability of steep slopes has been consistent. Kim et al. [6] analysed the stability of slopes using geotextiles, and Salamatpoor and Salamatpoor [17] improved slope stability using blended ground materials. Nadi et al. [12] assessed slope stability by investigating the seepage of water through rock-jointed materials. Subsequently, Nadi et al. [13] proposed a method for evaluating the seismic response of slopes based on the shear wave velocity in soil.

The safety of employing a reinforced retaining wall is ensured by installing horizontal reinforcements to reduce earth pressure by leveraging the frictional resistance imparted by the backfill. In view of its simplicity, this approach is deemed economical. Accordingly, the publication of paper on reinforced soil retaining walls has continued.

Kim [7] observed the behaviour of the ground supported by retaining walls via a model test. Subsequently, they proposed Eq. (2), which is an expression that considers the retaining wall height, reinforcement spacing, and reinforcement length. The ground was simulated using 1.6 and 3.0 mm thick aluminum rods. The vertical wall was built outdoors to observe the stability or collapse of the reinforced retaining wall through photo-shooting techniques. Employing Eq. (2), the required reinforcement length obtained was 1.40 m, which was between the lengths in cases 1 and 2. This confirmed that the case conditions in the study were appropriate.

L: Reinforcement length; H: Height of retaining wall; and D: Applied spacing of reinforcements.

In retaining walls, the generated stress concentrations in the curved sections exceed those in the straight parts. This phenomenon leads to front wall bulging, cracking, and collapse. Moreover, the lack of design standards or relevant information because of limited research can lead to unsafe construction.

Ki et al. [5] analysed the behaviour of reinforced retaining walls according to their convex and concave shapes through laboratory model tests. In both wall shapes, the maximum horizontal displacement occurred in the curved sections. Moreover, the generated horizontal displacements were greater in the convex-shaped reinforced retaining wall than in the wall with a concave shape. Based on the foregoing, the condition of the convex-shaped reinforced soil retaining wall was chosen. And, the behaviours of the curved and straight parts were compared in terms of the reinforcement length in this study.

Lee et al. [10] investigated the extent of damage in reinforced retaining walls and analysed the behaviours of the straight and curved sections (convex and concave) using numerical analysis. In their study, the reinforced soil retaining wall height was 5.2 m, and the reinforcement length was 4.2 m. Lee et al. [10] found that the horizontal displacements and settlements in the curved parts were larger in the case of the convex-shaped wall than in the concave-type reinforced retaining wall. The 5.2 m convex-shaped retaining wall was adopted in this study, and reinforcements of various lengths were considered to determine the most appropriate length.

Kong et al. [8] predicted the fracture behaviours of curved and straight parts based on the reinforced retaining wall height using 3D numerical analysis. Bulging was observed to increase with the wall height, and larger horizontal displacements occurred in the curved sections than in the straight parts. In this study, based on the four cases of Kong et al. [8] the wall height in case 2, i.e., 5.2 m, was adopted (2018), satisfying the minimum height of 5 m of reinforced soil retaining walls. Their study found that horizontal displacement increased with the wall height; this tendency was also observed in the present study.

Lee et al. [11] regarded the degradation of the retaining wall drainage as the cause of wall bulging. Subsequently, they predicted the extent of wall of displacement based on field test results. Through numerical analysis, the reinforcement interval of the soil nail was calculated, and stability was assessed to preclude bulging. The soil nail length and spacing were calculated as 5.0 and 1.5 m, respectively. Moreover, their study confirmed that horizontal displacement (i.e., bulging) rarely occurred after reinforcing the region where displacement generally occurred. This study compares the reinforcement effects according to the reinforcement length using geogrid, which is primarily employed as soil retaining wall reinforcement along with soil nailing. In future field tests, geogrids will potentially be used.

Several studies on reinforced retaining walls and reinforcements have been conducted [1, 4, 14, 18]. The current study found that the use of the same reinforcement length for the straight and curved sections of retaining walls for construction convenience was problematic. This approach can lead to wall collapse accidents because of inadequate reinforcement or may be uneconomical because of over-reinforcement. Accordingly, the present work aims to predict the reinforcement effect based on reinforcement length using 3D numerical analyses. Reinforcements of different lengths are installed in the curved and straight sections, and strategies for improving economy are suggested.

Numerical analysis

Modelling

This study analysed the behaviour of reinforced retaining walls based on the length of reinforcements using PLAXIS 3D (PLAXIS, Netherlands, [16]). PLAXIS 3D is a widely utilised finite element analysis programme for 3D geotechnical engineering because it has tools that are easy to use and calculation procedures that are theoretically robust. As summarised in Table 1, based on the reinforcement length, four cases (1, 3, 5, and 7 m) are considered in this study. These reinforcements were installed at 0.4 m intervals in retaining walls of the same height (5.2 m); the numerical analysis is modelled, as shown in Fig. 3(a). The designed dimensions of these walls are 10 m × 10 m × 5.2 m (length × width × height), composed of 0.4 m × 0.5 m × 0.4 m blocks (length × width × height). The interface behaviour of the ground was modelled using interface elements (Rinter) between the soil, wall, and reinforcement. PLAXIS 3D uses a zero-thickness element among the various interface model elements because it is logically valid. In this study, Rinter is 0.8. The embedded depth of the wall is set to 0.4 m according to Kwon et al. [9]. Based on literature, the surface load on top of the backfill is set equal to 100 kN. The modelling and mesh of the four cases according to the reinforcement length are shown in Figs. 3b–d.

The Mohr–Coulomb model (associated flow rule) was used for the original ground and backfill, and the linear–elastic model was employed for the retaining wall. According to Das [3], the backfill compaction was determined to be that of dense soil with a relative density of 80%. Recently, ground stabilisation using mixed materials has been increasing such as Salamatpoor and Salamatpoor [17]). In this study, to investigate the differences in ground behaviour, the ground material parameters were selected from existing literature, thereafter, the wall reinforcements were compared. In the further study, research should be conducted on construction methods yielding better stability according to compare with the blended backfill material and the reinforcements. Based on the work of Yoo et al. [19], reinforcements with a design strength 50 kN/m (EA) was applied in this study. Table 2 summarises the material parameters of the original ground, backfill, and retaining walls [3, 10, 15].

Results of numerical analysis

Horizontal displacements

Bulging occurs in both straight and curved parts due to the loads on top of the backfill. In the straight parts of the retaining wall, bulging occurs at the top because of overturning. Different from the straight parts, bulging occurs at the lower curved section because of the tensile force induced by the surface loads and earth pressure. As the stiffener length is increased, the potential occurrence of the bulging phenomenon decreases. The horizontal displacements of the curved and straight parts according to the reinforcement length are shown in Fig. 4. The maximum horizontal displacements in the straight parts of the retaining wall decreased by 37.39, 40.15, and 46.83% in cases 2–4, respectively, and those of the curved parts decreased by 17.53, 23.28, and 26.42%, respectively, compared with the displacements in case 1 in these parts. The decreasing rates of horizontal displacements in the curved and straight sections are shown in Fig. 5. The average wall heights calculated using Eqs. (1) and (2) for the straight and curved sections were 1.47 and 1.40 m, respectively; the numerical analysis yielded similar results. The reinforcement effect was low in case 1 but rapidly increased in case 2. When the reinforcement length exceeded 3 m, the rate of horizontal displacements did not considerably vary.

Vertical displacements and ground surface settlements

The ground surface settlement in each case was measured in the C–C' section, as shown in Fig. 6. The straight and curved sections were separated at the 4 m and 8 m positions, respectively. In each case, ground surface settlements were greater in the curved sections than in the straight sections. The ground surface settlements in the straight sections decreased by 12.95, 25.97, 23.52, and 26.84% compared with the ground surface settlements in the curved section at corresponding locations. Moreover, in case 1 (reinforcement length = 1 m), the generated ground surface settlements exceed those in the other cases. The differences in the ground surface settlements between cases 1 and 2 in the curved and straight parts are 12.41 and 25.51%, respectively. Therefore, for safe design, it is necessary to select a reinforcement length that exceeds 1 m. the vertical displacements in the four cases are shown in Fig. 7. The vertical displacement was considerable in the curved section in case 1. When the reinforcement lengths were 3 m or more (cases 2–4), the vertical displacement significantly decreased. This trend is consistent with the results shown in Fig. 6. This is because the suppression of soil displacement is not possible when the reinforcement length is short. However, when the reinforcement length is sufficient, stable vertical displacement results are obtained, as shown in Fig. 7b–d. The decrease rate in ground surface settlements with the increase in reinforcements length in the curved and straight parts is shown in Fig. 8; cases 2–4 compared with case 1 decrease by 25.5, 28.25, and 32.12% in the straight parts, respectively, and decrease by 12.41, 18.34, 19.23% in the curved parts, respectively. These results suggest that when the reinforcement length is 3 m or more, ground surface settlements rapidly decrease. Hence, if the reinforcement length is sufficient, then the decrease rate of ground surface settlements is low. Accordingly, it is necessary to focus on the reinforcements of the curved parts rather than those of the straight parts, cognizant that excessive amounts of reinforcement reduce economic efficiency.

Total displacement vectors

The total displacement vectors are shown in Fig. 9. These vectors decrease as the stiffener lengths increase; they rapidly decrease in cases 2–4 compared with that in case 1. The curved section is determined to be weak because the vectors are concentrated in this section. Hence, in the curved sections, the use of reinforcements with appropriate lengths and the introduction of countermeasures in the design and construction of retaining walls are crucial.

Varying reinforcement lengths in curved and straight sections

Based on the previous 3D numerical analysis, another numerical analysis of the straight and curved sections with reinforcements of different lengths was performed. The horizontal displacement In the curved sections was found to be approximately twice that in the straight sections. Accordingly, as shown in Fig. 10a 1 and 3 m long reinforcements are employed in the straight and curved sections, respectively. The vertical displacements are shown in Fig. 10b. In the curved sections, the vertical displacements are shorter than those shown in Fig. 7a. The horizontal displacements in the straight and curved parts in all cases are shown in Fig. 11. In case 5 (red line), 1 m and 3 m long reinforcements are used in both straight and curved parts. As shown in Fig. 11b, the same reinforcement effect is achieved in the curved parts by employing 3 m long reinforcements; however, in the straight parts, the horizontal displacements decrease by up to 9.72% at the top of the wall (4 m point) due to the stiffener applied to the curved section. Therefore, it is economical to employ 1 and 3 m long reinforcements in the straight and curved sections, respectively, instead of only using 3 m long reinforcements in these sections. Moreover, the use of these reinforcement lengths is safer than solely installing 1 m long reinforcements in both sections.

Conclusions

This study predicted the behaviours of the straight and curved sections of reinforced retaining walls according to the reinforcement length using 3D numerical analysis. The derived results are summarised as follows.

1. The overall failure of the reinforced retaining wall appears in the form of wall bulging, which decreases as the reinforcement length increases. The horizontal displacements according to the reinforcement length in cases 2–4 compared with case 1 were reduced by 37.39%, 40.15%, and 46.83%, respectively, in the straight sections, whereas those in the curved sections decreased by 17.53, 23.28, and 26.42%, respectively. These results suggest that in case 1, the reinforcement effect is low, whereas the reinforcement effect in cases 2–4 (reinforcement length = 3 m or longer) is sufficient. However, the variation of this effect between cases 2–4 is insignificant. Hence, sufficient reinforcement lengths lead to a stable retaining wall, and excessive reinforcement amounts reduce economic efficiency.

2. In case 1 (reinforcement length: 1 m), as the reinforcement length increased from 1 to 3 m, the ground surface settlements and vertical displacements rapidly decreased, and the total vertical displacement vectors sharply increased. The ground surface settlements in cases 2–4 compared with that in case 1 in the straight sections, decreased by 25.5 28.25, and 32.12%, respectively, whereas those in the curved sections decreased by 12.41, 18.34, and 19.23%, respectively; these confirmed that the reinforcement length should exceed 1 m. In addition, the ground surface settlements in the straight sections compared with those in the curved sections decreased by 12.95, 25.97, and 23.52% in cases 2–4, respectively. Thus, additional reinforcements are required in the curved sections. Short reinforcement lengths lead to insufficient reinforcements; hence, it is important to ensure that the reinforcements in curved sections are adequate.

3. In the numerical analysis, different reinforcement lengths, i.e., 1 and 3 m, were used in the straight and curved sections, respectively. In the curved sections, the reinforcement effect in terms of the vertical displacements was the same. However, the horizontal displacements in the straight sections decreased by 9.72% at the top of the wall (4 m point) as a result of the reinforcements applied to the curved sections. Therefore, instead of using the same reinforcement length, it is economical to employ different lengths in the straight and curved sections. In the future, the authors intend to conduct research on the optimal stiffener length and its details through model tests.

References

Baral P, Bergado DT, Duangkhae S (2016) The use of polymeric and metallic geogrid on a full-scale MSE wall/embankment on hard foundation: a comparison of field data with simulation. Int J Geo-Eng 7(1):1–29

Chun BS, Kang IG, Kang IS, Ko GS, Ko YI, Kwon HS, Kim KM, Kim DY, Kim BH, Kim SR, Kim WC, Kim JC, Nam SS, Do JN, Park DH, Park HG, Sa GM, Song CY, Shin YH, Ahn SR, Ahn TB, Yoe YH, Oh MY, Yoo HK, Lee SH, Lee TY, Lim HS, Jung HC, Jung HS, Jo CH, Jin MS, Chae HY, Choi CS, Ha KH, Hwong SG (2012) Geotechnical engineering—theory and practice. Goomibook, Seoul, pp 328–334

Das BM (2009) Principles of geotechnical engineering. CENGAGE Leaning, Boston, pp 302–367

Jung HS (2017) Comparison of behaviour of straight and curved mechanically stabilized earth walls from numerical analysis results. J Korean Geosynth Soc 16(4):83–92

Ki JS, Rew WH, Kim SK, Chun BS (2012) A behavior of curve section of reinforced retaining wall by model test. Korean Soc Civil Eng 32(6):249–257

Kim KM, Kim HT, Lee HK (2005) Slope stability analysis considering reinforcing effects od geosynthetics. J Korean Geo-Environ Soc 6(1):73–82

Kim ST (2005) Critical faolure condition of reinforced earth wall by change of length and vertical distance of reinforcements, Master thesis, University of Sunchon, Seoul, p 43–44.

Kong SM, Lee JH, Jung HS, Lee YJ (2018) 3D numerical prediction of failure behaviour for the straight and curved parts of retaining wall according to various heights. Int J Geo-Eng 9(1):1–18

Kwon HJ, Kim DS, Park JB, Jung SK (2011) Foundation engineering. Goomibook, Seoul, pp 320–325

Lee JH, Oh DW, Kong SM, Jung HS, Lee YJ (2018) Investigation of behaviours of wall and adjacent ground considering shape of geosynthetic retaining wall. J Korean Geosynth Soc 17(1):95–109

Lee WH, Moon BJ, Lee SY (2019) A study on reinforcement method of reinforced soil retaining wall through field experiment. J Korea Inst Struct Maint Insp 23(4):103–112

Nadi, B., Tavasoli, O., Kontoni D. N., Tadayon, A. (2019), “Investigation of rock slope stability under porewater pressure and structural anisotropy by the discrete element method”, Geomechanics and Geoengineering, pp.1–13.

Nadi B, Tavasoli O, Esfeh PK, Kontoni DN (2020) Characteristics of spatial variability of shear wave velocity on seismic response of slopes. Arab J Geosci. https://doi.org/10.1080/17486025.2019.1680879

Oh DW, Kong SM, Lee JH, Hong SK, Jung HS, Lee YJ (2018) Behaviour characteristic of convex for geosynthetic retaining wall according to curvature radius. In: Proceedings of the 11th international conference on geosynthetics, p 16–21.

Patki MA, Mandal JN, Dewaikar DM (2015) Computation of passive earth pressure coefficients for a vertical retaining wall with inclined cohesionless backfill. Int J Geo-Eng 6(1):1–17

Plaxis (2018) Plaxis 3D reference manual, p 85–90. Plaxis

Salamatpoor S, Salamatpoor S (2017) Evaluation of adding crushed glass to different combinations of cement-stabilized sand. Int J Geo-Eng 8(1):1–12

Sridhar R, Kumar MTP (2018) Effect of number of layers on coir geotextile reinforced sand under cyclic loading. Int J Geo-Eng 9(1):1–14

Yoo CS, Jung HS, Lee SW (2004) A case study of the collapsed retaining wall. J Korean Geosynth Soc 3(2):13–21

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. NRF-2017R1A2B2055676 and NRF-2017R1A2B2012993).

Author information

Authors and Affiliations

Contributions

SMK has drafted and revised the manuscript. DWO and SYL have contributed on numerical analysis. HSJ and YJ Lee have contributed on conception and design of the study. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kong, S.M., Oh, DW., Lee, SY. et al. Analysis of reinforced retaining wall failure based on reinforcement length. Geo-Engineering 12, 13 (2021). https://doi.org/10.1186/s40703-021-00143-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-021-00143-6