Abstract

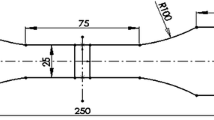

The formations and fracture behavior of the AA2A14-T6 aluminum alloy friction stir welded (FSWed) joints are investigated under different ratios of rotational speed to welding speed (n/v). The relationship between the viscous layer (δ) and the rheological layer (ξ) is the key factor to determine the welding quality of joints. When δ < ξ, loose microstructure, needle-like, dispersive, or through void is generated in the joint as the n/v decreases. When δ ≥ ξ, the defect-free joints can be obtained. The through void greatly weakens the tensile properties, and the tensile specimens fracture in the stir zone (SZ). Other defects mainly influence the ultimate strength and the elongation, and the joints fracture at the SZ/thermo-mechanically affected zone or the base material/heat-affected zone (BM/HAZ). The defect-free joints have the largest tensile properties and fracture at the BM/HAZ. Based on the above analysis, the reasonable quality assessment criteria of the FSWed joint need to combine with four aspects: internal formation, strength, plasticity, and fracture behavior. Meanwhile, according to the reasonable matching relationship between δ and ξ, the critical conditions of FSW process parameters for the 2A14-T6 aluminum alloy can be obtained.

Similar content being viewed by others

References

Amir M, Taher A, Milad M, Rezgar H (2019) Tensile properties of friction stir welding of thermoplastic pipes based on a novel designed mechanism. Weld World 63:691–699

Huang YX, Meng XC, Xie YM et al (2018) Friction stir welding/processing of polymers and polymer matrix composites. Compos A Appl Sci Manuf 105:235–257

Sun T, Roy MJ, Strong D et al (2018) Weld zone and residual stress development in AA7050 stationary shoulder friction stir T-joint weld. J Mater Process Technol 263:256–265

Yan X, Ma H, Xiong LY et al (2018) Effect of lateral offset on microstructure and strength of friction stir welded 2A14-T6 aluminum alloy. Int J Adv Manuf Technol 97:3893–3902

Ambrosio D, Wagner V, Garnier C, Jacquin D, Tongne A, Fazzini M, Cahuc O, Dessein G (2020) Influence of welding parameters on the microstructure, thermal fields and defect formation in AA7075-T6 friction stir welds. Weld World 64:773–784

Meng XC, Huang YX, Cao J et al (2021) Recent progress on control strategies for inherent issues in friction stir welding. Prog Mater Sci 115:100706. https://doi.org/10.1016/j.pmatsci.2020.100706

Mishra RS, Sidhar H (2016) Friction stir welding of 2XXX aluminum alloys including Al-Li alloys. Denton, USA

Patel V, Li W, Wang G, Wang F, Vairis A, Niu P (2019) Friction stir welding of dissimilar aluminum alloy combinations: state-of-the-art. Metals 9(3). https://doi.org/10.3390/met9030270

Liu HJ, Fujii H, Maeda M, Nogi K (2003) Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy. J Mater Process Technol 142(3):692–696

Radisavljevic I, Zivkovic A, Radovic N, Grabulov V (2013) Influence of FSW parameters on formation quality and mechanical properties of Al 2024-T351 butt welded joints. Trans Nonferrous Metals Soc China 23(12):3525–3539

Chen ZW, Cui S (2007) Tool-workpiece interaction and shear layer flow during friction stir welding of aluminium alloy. Trans Nonferrous Metals Soc China A01:258–261

Ma H, Wang Y, Tian ZJ et al (2019) Gap-tolerance control for friction stir butt welding of 2A14 aluminium alloy. Measurement. 148:106915. https://doi.org/10.1016/j.measurement.2019.106915

Ma H, Tian ZJ, Xiong LY et al (2018) Thermal behavior and pre-molten viscousness layer simulation of friction stir welding on 2A14-T6 aluminum alloy. Aeron Manuf Tech 61(8):55–61

Pei X, Dong P (2017) A selectively-coupled shear localization model for friction stir welding process window estimation. Int J Mach Tool Manu 123:89–104

Le Jolu T, Morgeneyer TF, Denquin A et al (2014) Microstructural characterization of internal welding defects and their effect on the tensile behavior of FSW joints of AA2198 Al-Cu-Li alloy. Metall Mater Trans A 45(12):5531–5544. 2

Singh VP, Patel SK, Kuriachen B, Suman S (2020) Investigation of general welding defects found during friction-stir welding (FSW) of aluminium and its alloys. Advances in Additive Manufacturing and Joining. https://doi.org/10.1007/978-981-32-9433-2_51

Morishige T, Kawaguchi A, Tsujikawa M, Hino M, Hirata T, Higashi K (2008) Dissimilar welding of Al and Mg alloys by FSW. Mater Trans 49(5):1129–1131

Luo J, Xiang JF, Yuan L, Lin HX, Wu XR, Xie DZ (2020) Heat transfer and metal flow behavior of AA7075 high-strength aluminum alloy in a new current-induced friction stir welding with a multi-physics field model based on the inverse method and parameter scanning batch processing technique. Int J Adv Manuf Technol 111:2615–2635

Jiang HJ, Zhang B, Liu CY, Yang ZX, Ma ZY (2019) Mechanical and damping behavior of age-hardened and non-age-hardened Al alloys after friction stir processing. Acta Metall Sin 32:1135–1141

Gemme F, Verreman Y, Dubourg L et al (2011) Effect of welding parameters on microstructure and mechanical properties of AA7075-T6 friction stir welded joints. Fatigue Fract Eng M 34(11):877–886

Patel V, Li W, Vairis A, Badheka V (2019) Recent development in friction stir processing as a solid-state grain refinement technique: microstructural evolution and property enhancement. Crit Rev Solid State 44(5):378–426

Wu TK, Luo HT, Guo H et al (2019) Numerical simulation of temperature field and material flow in friction stir welding. Adv Intell Syst Res 168:333–338

Tao BH, Xia F, Zhang TH (2019) Effect of welding parameters on junction structure and fracture behavior of friction-stir-welded joints of 2024 aluminum alloys. J Mater Eng Perform 28(8):5172–5185

Chen HB, Yan K, Lin T, Chen SB, Jiang CY, Zhao Y (2006) The investigation of typical welding defects for 5456 aluminum alloy friction stir welds. Mater Sci Eng 433(1-2):64–69

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Wang, Y., Ma, H., Chai, P. et al. Strength and fracture behavior of AA2A14-T6 aluminum alloy friction stir welded joints. Weld World 65, 1483–1499 (2021). https://doi.org/10.1007/s40194-021-01131-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01131-1