Abstract

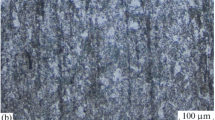

NiTi wire coating was preplaced on super austenitic stainless steel (904L) for enhancing the surface mechanical property. Melting of NiTi wire of 1 mm diameter formed a clad track on the 904L stainless steel substrate using the TIG cladding process. The influence of TIG current on microstructure, phase formation, micro-hardness and abrasive wear resistance characteristics of the clad surface have been investigated. The maximum average micro-hardness of the NiTi clad layer was 952HV at current of 40 A which is 5.95 times greater than the substrate material 904L. The EDS and XRD study of the NiTi coating layer confirmed the formation of NiTi, NiTi2, and B2 (NiTiFeCr) structure as major constituent phases and some intermetallic (Cr-Fe-Ni) which improved the mechanical properties of the clad layer. The pin on disc type sliding abrasive wear of the NiTi clad layer showed the improvement of wear resistance up to 8.83 times compared to the substrate 904L.

Similar content being viewed by others

References

Kwok C T, Man H C and Cheng F T 1998 Cavitation erosion and pitting corrosion of laser surface melted stainless steels. Surf. Coat. Technol. 99(3): 295–304

Sathiya P, Aravindan S, Jeyapaul R, Ajith P M and Haq A N 2010 Optimizing the weld bead characteristics of super austenitic stainless steel (904L) through grey-based Taguchi method. Multidiscip. Model. Mater. Struct. 6: 206–213

Frenzel J, George E P, Dlouhy A, Somsen C, Wagner M X and Eggeler G 2010 Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 58(9) 3444–3458

Eggeler G, Hornbogen E, Yawny A, Heckmann A and Wagner M 2004 Structural and functional fatigue of NiTi shape memory alloys. Mater. Sci. Eng. A 378(1–2): 24–33

Elahinia M, Moghaddam N S, Andani M T, Amerinatanzi A, Bimber B A and Hamilton R F 2016 Fabrication of NiTi through additive manufacturing: A review. Prog. Mater Sci. 83: 630–663

Man H C, Zhang S, Cheng F T and Guo X 2006 In situ formation of a TiN/Ti metal matrix composite gradient coating on NiTi by laser cladding and nitriding. Surf. Coat. Technol. 200(16–17): 4961–4966

Chiu K Y, Cheng F T and Man H C 2005 Laser cladding of austenitic stainless steel using NiTi strips for resisting cavitation erosion. Mater. Sci. Eng. A 402(1–2): 126–134

Lin Y, Lei Y, Fu H and Lin J 2015 Mechanical properties and toughening mechanism of TiB2/NiTi reinforced titanium matrix composite coating by laser cladding. Mater. Des. 80: 82–88

Ozel S, Kurt B, Somunkiran I and Orhan N 2008 Microstructural characteristic of NiTi coating on stainless steel by plasma transferred arc process. Surf. Coat. Technol. 202(15): 3633–3637

Verdian M M, Raeissi K and Salehi M 2010 Electrochemical impedance spectroscopy of HVOF-sprayed NiTi intermetallic coatings deposited on AISI 1045 steel. J. Alloys Compd. 507(1): 42–46

Hu W, Zhu H, Hu J, Li B and Qiu C. 2020 Influence of vanadium microalloying on microstructure and property of laser-cladded martensitic stainless steel coating. Materials 13(4): 826

Lepule M L, Obadele B A, Andrews A and Olubambi P A 2015 Corrosion and wear behaviour of ZrO2 modified NiTi coatings on AISI 316 stainless steel. Surf. Coat. Technol. 261: 21–27

Stella J, Schüller E, Heßing C, Hamed O A, Pohl M and Stöver D 2006 Cavitation erosion of plasma-sprayed NiTi coatings. Wear 260(9–10): 1020–1027

Cheng F T, Lo K H and Man H C 2004 A preliminary study of laser cladding of AISI 316 stainless steel using preplaced NiTi wire. Mater. Sci. Eng. A 380(1–2): 20–29

Chiu K Y, Cheng F T and Man H C 2005 Cavitation erosion resistance of AISI 316L stainless steel laser surface-modified with NiTi. Mater. Sci. Eng. A 392(1–2): 348–358

Chiu K Y, Cheng F T and Man H C 2005 A preliminary study of cladding steel with NiTi by microwave-assisted brazing. Mater. Sci. Eng. A 407(1–2): 273–281

Jeyaprakash N, Yang C H and Sivasankaran S 2020 Laser cladding process of Cobalt and Nickel based hard-micron-layers on 316L-stainless-steel-substrate. Mater. Manuf. Processes 35(2): 142–151

Li B, Zhu H, Qiu C and Gong X 2020 Laser cladding and in-situ nitriding of martensitic stainless steel coating with striking performance. Mater. Lett. 259: 126829

Skhosane B S, Tlotleng M and Pityana S L 2020 Effects of niobium (Nb) on mechanical properties of laser coated Nitinol (NiTi) used for surface modification of Ti6Al4V alloy. MRS Adv. 5(23–24): 1235–1244

Swain B, Mallick P, Bhuyan S K, Mohapatra S S, Mishra S C and Behera A 2020 Mechanical properties of NiTi plasma spray coating. J. Therm. Spray Technol. 29: 741–755

Khan M S, Enrique P, Song G, Faria M I S T and Zhou Y 2020 Laser-assisted wire cladding using a retrofitted laser welding system. Surf. Eng. 36: 1–8

Hebbale A M and Srinath M S 2016 Microstructure and experimental design analysis of nickel based clad developed through microwave energy. Perspect. Sci. 8: 257–259

Singh J, Thakur L and Angra S 2020 A study of tribological behaviour and optimization of WC-10Co-4Cr Cladding Surf. Eng. 386: 1–10

Azwan M, Maleque M A and Rahman M M 2019 TIG torch surfacing of metallic materials—a critical review. Trans. Inst. Met. Finish 97(1): 12–21

Rafiei M, Javadi M, Mostaan H and Abbasian A R 2020 The role of Si on solidification behaviour of the NiAl intermetallic cladding produced by the GTAW process. Can. Metall. Q. 59(3): 1–8

Lei Y, Tao L I, Qin M, Chen X and Yimin Y E 2011 Cavitation erosion resistance of co alloy coating on 304 stainless steel by TIG cladding. Trans. China Weld. Inst. 32(7): 9–12

Cheng F T, Lo K H and Man H C 2003 NiTi cladding on stainless steel by TIG surfacing process: Part I Cavitation erosion behavior. Surf. Coat. Technol. 172(2–3): 308–315

Lailatul P H and Maleque M A 2017 Surface modification of duplex stainless steel with SiC preplacement using TIG torch cladding. Procedia Eng. 184: 737–742

Garbyal J S, Padhee C K, Raheem A and Masanta M 2019 Sliding Abrasive and Adhesive Wear Behavior of TIG-Cladded NiTi–W Coating Deposited on Ti–6Al–4V Alloy. In Advances in Micro and Nano Manufacturing and Surface Engineering Lect. Notes Multidiscip. Ind. Eng. Springer, 603–611

Waghmare D T, Padhee C K, Prasad R and Masanta M 2018 NiTi coating on Ti-6Al-4V alloy by TIG cladding process for improvement of wear resistance: Microstructure evolution and mechanical performances. J. Mater. Process. Technol. 262: 551–561

Cameron N and Farhat Z 2019 Investigation into the Wear and Dent Resistance of Ni/Ti Nanolaminates and Superelastic NiTi Coating. J. Mater. Eng. Perform. 28(10): 6033–6041

Wang J, Pan Z, Wang L, Su L, Carpenter K, Wang J, Wang R and Li H 2020 In-situ dual wire arc additive manufacturing of NiTi-coating on Ti6Al4V alloys: Microstructure characterization and mechanical properties. Surf. Coat. Technol. 386: 125439

Prasad R, Waghmare D T, Kumar K and Masanta M 2020 Effect of overlapping condition on large area NiTi layer deposited on Ti-6Al-4V alloy by TIG cladding technique. Surf. Coat. Technol. 385: 125417

Shi Z P, Wang Z B, Wang J Q, Qiao Y X, Chen H N, Xiong T Y and Zheng YG 2020 Effect of Ni interlayer on cavitation erosion resistance of NiTi cladding by tungsten inert gas (TIG) surfacing process. Acta Metall. Sinica. (English Letters), 33(3): 415–424

Kumar P and Sinha A N 2019 Effect of heat input in pulsed Nd: YAG laser welding of titanium alloy (Ti6Al4V) on microstructure and mechanical properties. Weld. World 63(3): 673–689

Kumar S and Shahi A S 2011 Effect of heat input on the microstructure and mechanical properties of gas tungsten arc welded AISI 304 stainless steel joints. Mater. Des. 32(6): 3617–3623

Kim H J and Kim Y J 1999 Wear and corrosion resistance of PTA weld surfaced Ni and Co based alloy layers. Surf. Eng. 15(6): 495–501

Gao F and Wang H M 2008 Dry sliding wear property of a laser melting/deposited Ti2Ni/TiNi intermetallic alloy. Intermetallics 16(2): 202–208

Ghosh M and Chatterjee S 2003 Diffusion bonded transition joints of titanium to stainless steel with improved properties. Mater. Sci. Eng. A 358(1–2): 152–158

Anstis G R, Chantikul P, Lawn B R and Marshall D B 1981 A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 64(9): 533–538

Lima M M, Godoy C, Modenesi P J, Avelar-Batista J C, Davison A and Matthews A 2004 Coating fracture toughness determined by Vickers indentation: an important parameter in cavitation erosion resistance of WC–Co thermally sprayed coatings. Surf. Coat. Technol. 177: 489–496

Acknowledgements

This research work was supported by Indian Institute of Technology Kharagpur and Aditya College of Engineering and Technology. Mechanical and microstructure characterization was performed at Indian Institute of Technology Kharagpur.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, P., Sinha, A.N., Saravanan, A. et al. Study of microstructure and mechanical properties of NiTi wire cladding on super austenitic stainless steel 904L by TIG cladding process. Sādhanā 46, 91 (2021). https://doi.org/10.1007/s12046-021-01602-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01602-7