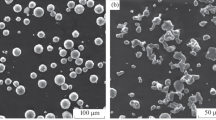

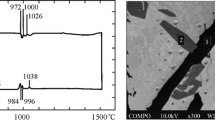

The phase formation and consolidation processes in TiH2–Ni powder mixtures resulting in TiNi intermetallic were studied. The use of titanium hydride as a precursor in optimal sintering conditions (900–1000°C) allowed a material with optimum porosity to be produced and a liquid phase to be avoided during sintering. The phase formation processes were found to occur rapidly in the sintering of TiH2–Ni mixtures. At sintering temperatures of 900–1000°C, 70–82% TiNi formed. Intermetallic Ti2Ni compound was an additional phase that emerged in the material in all sintering conditions. The stability of this phase was attributed to its affinity for oxygen and thus formation of stable complex oxides. The superfine mixture and highly active titanium resulting from the decomposition of titanium hydride accelerated the oxidation process. Moreover, the interaction with oxygen began sooner than with nickel. The samples produced from the finest mixture were less homogeneous than the samples produced from a coarser mixture. The high-speed interaction between titanium and nickel and rapid oxygen absorption were due to the hydride powder with significantly finer particles. In these sintering conditions, the material had 12–15% porosity and was thus optimum for medical applications. Studies of the mechanical behavior of TiNi alloys revealed an abnormally low elastic modulus of 40 GPa. Experiments on cyclic loading–unloading showed that the initial elastic strain was 1.1% and reversible transformation strain 0.7%. When the strain reached 4%, the elastic modulus decreased to E ~ 32.7 GPa, the total elastic strain increased to εel ~ 2.6%, and damping capability Q–1 became equal to 0.036. The mechanical characteristics of the materials were close to those of human bones. The experimental results demonstrate that the sintered TiN materials exhibit the structure and mechanical properties that make them promising for the design of human bone implants.

Similar content being viewed by others

References

K. Otsuka and X. Ren, “Physical metallurgy of Ti–Ni-based shape memory alloys,” Prog. Mater. Sci., 50, 511–678 (2005).

Bing-Yun Li, Li-Jian Rong, and Yi-Yi Li, “The influence of addition of TiH2 in elemental powder sintering porous Ni–Ti alloys,” Mater. Sci. Eng., A281, 169–175 (2000).

S.K. Sadrnezhaad and S.A. Hosseini, “Fabrication of porous NiTi-shape memory alloy objects by partially hydrided titanium powder for biomedical applications,” Mater. Des., 30, 4483–4487 (2009).

G. Chen, K.-D. Liss, and P. Cao, “An in situ Study of NiTi powder sintering using neutron diffraction,” Metals, 5, 530–546 (2015).

N.A. Krylova, Yu.N. Podrezov, V.I. Danilenko, I.I. Ivanova, and V.A. Barabash, “Effect of process and structural factors on the mechanical properties of titanium sintered from titanium hydrides,” Powder Metall. Met. Ceram., 58, No. 5–6, 270–277 (2019).

J. Liu and J. Van Humbeeck, “On the damping behavior of TiNi shape-memory alloys,” J. Phys. IV, 7, 519–524 (1997).

M. Bönisch, M. Calin, J. Van Humbeeck, W. Skrotzki, and J. Eckert, “Factors influencing the elastic moduli, reversible strains and hysteresis loops in martensitic Ti–Nb alloys,” Mater. Sci. Eng. C, 48, 511–520 (2015).

J. Van Humbeeck, “Damping capacity of thermoelastic martensite in shape memory alloys,” J. Alloys Compd., 355, 58–64 (2003).

Yu.M. Podrezov, O.M. Malka, P.M. Romanko, and K.O. Valuiska, “Temperature sensitivity of pseudoelastic behavior of Mg and Mg–9Al–0.2Ca–0.08Ti alloy in loading–unloading cycles,” Elektron. Mikrosk. Mitsn. Mater., Issue 22, 76–85 (2016).

P.M. Romanko, V.V. Kholyavko, and N.M. Marchenko, “Effect of isothermal quenching on the pseudoelastic behavior of bainite iron,” World Sci., No. 1(41), 15–23 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 11–12 (536), pp. 15–26, 2020.

Rights and permissions

About this article

Cite this article

Ivanova, I., Podrezov, Y., Klymenko, V. et al. The Formation and Elastic Behavior of TiNi Intermetallic Sintered From a TiH2–Ni Powder Mixture. Powder Metall Met Ceram 59, 621–630 (2021). https://doi.org/10.1007/s11106-021-00197-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00197-2