Abstract

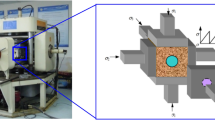

Facial support in slurry shield tunneling is provided by slurry pressure to balance the external earth and water pressure. Hydraulic fracturing may occur and cause a significant decrease in the support pressure if the slurry pressure exceeds the threshold of the soil or rock material, resulting in a serious face collapse accident. Preventing the occurrence of hydraulic fracturing in a slurry shield requires investigating the effects of related influencing factors on the hydraulic fracturing pressure and fracture pattern. In this study, a hydraulic fracturing apparatus was developed to test the slurry-induced fracturing of cohesive soil. The effects of different sample parameters and loading conditions, including types of holes, unconfined compressive strength, slurry viscosity, and axial and circumferential loads, on the fracturing pressure and fracture dip were examined. The results indicate that the fracture dip is mainly affected by the deviator stress. The fracturing pressure increases linearly with the increase in the circumferential pressure, but it is almost independent of the axial pressure. The unconfined compressive strength of soil can reflect its ability to resist fracturing failure. The fracturing pressure increases with an increase in the unconfined compressive strength as well as the slurry viscosity. Based on the test results, an empirical approach was proposed to estimate the fracturing pressure of the soil.

Similar content being viewed by others

References

Ryu Y M, Kwon Y S, Kim T H, Lee I M. Slurry clogging criteria for slurry shield tunnelling in highly permeable ground. KSCE Journal of Civil Engineering, 2019, 23(6): 2784–2793

Yuan D J, Huang Q F, Koizumi A, Wang M S. Study on slurry-water gushing during underwater shield tunnel construction. Journal of Rock Mechanics and Geotechnical Engineering, 2007, 026(011): 2296–2301

Liu X Y, Yuan D J. An in-situ slurry fracturing test for slurry shield tunnelling. Journal of Zhejiang University. Science A, 2014, 15(7): 465–481

Liu X Y, Yuan D J. Mechanical analysis of anti-buoyancy safety for a shield tunnel under water in sands. Tunnelling and Underground Space Technology, 2015, 47(3): 153–161

Baumert M E, Allouche E N, Moore I D. Experimental investigation of pull loads and borehole pressures during horizontal directional drilling installations. Canadian Geotechnical Journal, 2004, 41(4): 672–685

Nordgren R P. Propagation of a vertical hydraulic fracture. Society of Petroleum Engineers Journal, 1972, 12(04): 306–314

Jukkrawut T, Pornkasem J, Preecha S, Kongkitkul W, Nanakorn P. Analysis of fracture propagation in a rock mass surrounding a tunnel under high internal pressure by the element-free Galerkin method. Computers and Geotechnics, 2014, 55(1): 78–90

Lockner D, Byerlee J D. Hydrofracture in Weber sandstone at high confining pressure and differential stress. Journal of Geophysical Research, 1977, 82(14): 2018–2026

Zoback M D, Rummel F, Jung R, Raleigh C B. Laboratory hydraulic fracturing experiments in intact and pre-fractured rock. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1977, 14(2): 49–58

Ishijima Y, Kinoshita S, Ito Y, Machida K. Experimental study on hydrofracturing stress measurements. Journal of the Mining and Metallurgical Institute of Japan, 1980, 96(1114): 871–877

Harada T, Idemitsu T, Watanabe A. Demolition of concrete with expansive demolition agent. Doboku Gakkai Ronbunshu, 1985, 3(360): 61–70

Morgenstern N R, Vaughan P R. Some observations on allowable grouting pressure. In: Institution of Civil Engineers (Great Britain), International Society of Soil Mechanics and Foundation Engineering, Grouts and Drilling Muds in Engineering Practice. London: Butterworths, 1963: 36–42

Karol R H. Chemical Grouting and Soil Stabilization. New York: Marcel Dekker, 2003

Chen T L, Zhang L Y, Zhang D L. An FEM/VOF hybrid formulation for fracture grouting modelling. Computers and Geotechnics, 2014, 58(5): 14–27

Xiao F, Shang J, Zhao Z. DDA based grouting prediction and linkage between fracture aperture distribution and grouting characteristics. Computers and Geotechnics, 2019, 112(8): 350–369

Bjerrum L, Nash J K T L, Kennard R M, Gibson R E. Hydraulic fracturing in field permeability testing. Geotechnique, 1972, 22(2): 319–332

Qiao J L, Fan Y L, Liu B, Zhang Y P, Li Y Y. The research of backfill grouting pressure in shield tunnelling. Advanced Materials Research, 2012, 446–449: 2240–2245

Haimson B C. Hydraulic fracturing and rock characterization. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(suppl 1): 188–194

Gale J F W, Gomez L A. Late opening-mode fractures in karstbrecciated dolostones of the lower Ordovician Ellenburger group, West Texas: Recognition, characterization, and implications for fluid flow. AAPG Bulletin, 2007, 91(7): 1005–1023

Vaughan P R. The Use of Hydraulic Fracturing Tests to Detect Crack Formation in Embankment Dam Cores. Initial Report. London: Department of Civil Engineering, Imperial College, 1971

Jaworski G W, Duncan J M, Seed H B. Laboratory study of hydraulic fracturing. Proceedings ASCE, 1981, 107(GT6): 713–732

Mori A, Tamura M. Hydrofracturing pressure of cohesive soils. Soil and Foundation, 1987, 27(1): 14–22

Mori A, Tamura M, Fukui Y. Fracturing pressure of soil ground by viscous materials. Soil and Foundation, 1990, 30(3): 129–136

Zhuang X, Zhou S, Sheng M, Li G. On the hydraulic fracturing in naturally-layered porous media using the phase field method. Engineering Geology, 2020, 266: 105306

Zhou S, Rabczuk T, Zhuang X. Phase field modeling of quasi-static and dynamic crack propagation: COMSOL implementation and case studies. Advances in Engineering Software, 2018, 122: 31–49

Zhou S, Zhuang X, Rabczuk T. Phase-field modeling of fluid-driven dynamic cracking in porous media. Computer Methods in Applied Mechanics and Engineering, 2019, 350: 169–198

Zhou S, Zhuang X, Rabczuk T. A phase-field modeling approach of fracture propagation in poroelastic media. Engineering Geology, 2018, 240: 189–203

Rabczuk T, Belytschko T. Cracking particles: A simplified meshfree method for arbitrary evolving cracks. International Journal for Numerical Methods in Engineering, 2004, 61(13): 2316–2343

Ren H, Zhuang X, Rabczuk T. Dual-horizon peridynamics: A stable solution to varying horizons. Computer Methods in Applied Mechanics and Engineering, 2017, 318: 762–782

Talebi H, Silani M, Bordas S P A, Kerfriden P, Rabczuk T. A computational library for multiscale modeling of material failure. Computational Mechanics, 2014, 53(5): 1047–1071

Ishida T, Chen Q, Mizuta Y, Roegiers J C. Influence of fluid viscosity on the hydraulic fracturing mechanism. Journal of Energy Resources Technology, 2004, 126(3): 190–200

Tiegang F, Guangqing Z. Influence of injection rate and fracturing fluid viscosity on hydraulic fracture geometry in coal. Journal of China University of Petroleum, 2014, 38(4): 117–123 (in Chinese)

Li X, Zhang K, Bu X, Xu W, Li N, Wei L. Evaluations of repeated fracturings in old wells. Oil Geophysical Prospecting, 2018, 53(s2): 162–167 (in Chinese)

Zeng L P, Qi J F, Wang Y X. Origin type of tectonic fractures and geological conditions in low-permeability reservoirs. Acta Petrolei Sinica, 2007, 28(4): 52–56 (in Chinese)

Xu Z H, Zhang G D, Sun D W, Sun Q C. Discussion of deviatoric stress calculation in triaxial consolidation drained test. Journal of Yangtze River Scientific Research Institute, 2016, 33(4): 57–60

Vu-Bac N, Lahmer T, Zhuang X, Nguyen-Thoi T, Rabczuk T. A software framework for probabilistic sensitivity analysis for computationally expensive models. Advances in Engineering Software, 2016, 100(Oct): 19–31

Coleman H W, Steck W G Jr, Hurlbut F C. Experimentation and uncertainty analysis for engineers. Journal of Engineering for Industry, 1991, 113(2): 248–344

Jin D, Shen Z, Yuan D. Effect of spatial variability on disc cutters failure during TBM tunneling in hard rock. Rock Mechanics and Rock Engineering, 2020, 53(10): 4609–4621

Samaniego E, Anitescu C, Goswami S, Nguyen-Thanh V M, Guo H, Hamdia K, Zhuang X, Rabczuk T. An energy approach to the solution of partial differential equations in computational mechanics via machine learning: Concepts, implementation and applications. Computer Methods in Applied Mechanics and Engineering, 2020, 362: 112790

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant Nos. KCA313017533 and C16A300190).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, T., Yuan, D., Jin, D. et al. Experimental study on slurry-induced fracturing during shield tunneling. Front. Struct. Civ. Eng. 15, 333–345 (2021). https://doi.org/10.1007/s11709-021-0718-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0718-8