Abstract

Bulge testing is an experimental technique applied to the characterization of thin films, with which the mechanical properties are obtained employing numerical and analytical approaches. For rectangular and circular thin films, classical methods have been well adopted to calculate the stresses and strains at the central point without the dependency of its properties. It is due to that the equilibrium conditions are dependent on the curvatures generated at the maximum deflection point. Therefore, the kinematics of the bulged surface can be represented by a spherical cap and cylindrical shapes in these films. For square thin films, the deflected surface presents a complex displacement field that implies the development of analytical models for the estimation of these. In this sense, equations to represent the equibiaxial stress state (central point) for freestanding square thin films are developed and applied in this study. The curvatures are determined using a reviewed nonlinear deflection field. Virtual experiments were driven by applying finite element analysis to validate the stress and strain models through parametric analysis. In order to impose the residual stress in thin films, two approaches of modeling for the simulations are described. In order to validate the applicability of the proposed equations, different cases were presented for the linear elastic analysis, and two examples were developed to characterize elastoplastic behavior (bilinear and nonlinear) from load–deflection curves. The obtained results show that the developed models for square thin films are in good agreement with the finite element simulations since these predicted the stress and strain states with good accuracy.

Similar content being viewed by others

Abbreviations

- \(\sigma_{{\text{r}}}\) :

-

Residual stress

- \(E\) :

-

Young’s modulus

- \(v\) :

-

Poisson ratio

- \(K\) :

-

Fracture toughness

- \(\sigma_{{{\text{yp}}}}\) :

-

Yield stress

- \(N_{i}\) :

-

Force in i-direction \(i = \left\{ {x,y,z} \right\}\)

- \(w(x,y)\) :

-

Displacement field

- \(\kappa_{ii} (x,y)\) :

-

Curvatures field \(i = \left\{ {x,y,z} \right\}\)

- \(a\) :

-

Lower length side of a rectangular film

- \(b\) :

-

Higher length side of a rectangular film

- \(P\) :

-

Pressure

- \(\sigma_{xx0}\) :

-

Stress at the central point of a square thin film

- \(\sigma_{0}\) :

-

Stress at the central point of a rectangular thin film

- \(\varepsilon_{{{\text{yp}}}}\) :

-

Total strain in the elastic limit

- \(P_{{\text{l}}}\) :

-

Pressure in the elastic threshold

- \(w_{l}\) :

-

Maximum displacement in \(P_{l}\)-elastic threshold

- \(w_{0}\) :

-

Maximum displacement at the central point

- \(u_{0}\) :

-

Initial displacement in x-direction

- \(v_{0}\) :

-

Initial displacement at y-direction

- SD:

-

Standard deviation

- A:

-

Geometric factor in a shell

- \(\tan (\alpha )\) :

-

The slope of the stress–strain curve

- \(\rho_{i} (x,y)\) :

-

Curvatures radius \(i = \left\{ {x,y,z} \right\}\)

References

Ezhilvalavan, S., Tseng, T.Y.: Preparation and properties of tantalum pentoxide (Ta2O5) thin films for ultra large scale integrated circuits (ULSIs) application—a review. J. Mater. Sci.: Mater. Electron. 10(1), 9–31 (1999)

Fu, Y., Du, H., Huang, W., Zhang, S., Hu, M.: TiNi-based thin films in MEMS applications: a review. Sens. Actuators A 112(2–3), 395–408 (2004)

Mitchell, J.S., Zorman, C.A., Kicher, T., Roy, S., Mehregany, M.: Examination of bulge test for determining residual stress, Young’s modulus, and Poisson’s ratio of 3C-SiC thin films. J. Aerosp. Eng. 16(2), 46–54 (2003)

Poelma, R.H., Sadeghian, H., Noijen, S.P.M., Zaal, J.J.M., Zhang, G.Q.: A numerical experimental approach for characterizing the elastic properties of thin films: application of nanocantilevers. J. Micromech. Microeng. 21(6), 065003 (2011)

Zhou, W., Yang, J., Sun, G., Liu, X., Yang, F., Li, J.: Fracture properties of silicon carbide thin films by bulge test of long rectangular membrane. J. Microelectromech. Syst. 17(2), 453–461 (2008)

Merle, B., Göken, M.: Fracture toughness of silicon nitride thin films of different thicknesses as measured by bulge tests. Acta Mater. 59(4), 1772–1779 (2011)

Yanfei, C., Shigang, A., Jingda, T., Yongmao, P., Liqun, T., Daining, F.: Characterizing the viscoelastic properties of hydrogel thin films by bulge test. J. Appl. Mech. 10(1115/1), 4036394 (2017)

Tinoco, H.A., Holzer, J., Pikálek, T., Buchta, Z., Lazar, J., Chlupová, A., et al.: Determination of elastic parameters of Si3N4 thin films by means of a numerical approach and bulge tests. Thin Solid Films 672, 66–74 (2019)

Tinoco, H.A., Hutař, P., Merle, B., Göken, M., Kruml, T.: Fracture toughness evaluation of a cracked Au thin film by applying a finite element analysis and bulge test. Key Eng. Mater. 827, 196–202 (2019)

Xiang, Y., Vlassak, J.J.: Bauschinger and size effects in thin-film plasticity. Acta Mater. 54(20), 5449–5460 (2006)

Small, M.K., Nix, W.D.: Analysis of the accuracy of the bulge test in determining the mechanical properties of thin films. J. Mater. Res. 7(6), 1553–1563 (1992)

Lee, H.K., Ko, S.H., Han, J.S., Park, H.: Mechanical properties measurement of silicon nitride thin films using the bulge test. Microelectron. Design Technol. Packag. III 6798, 67981C (2007)

Min, J., Stoughton, T.B., Carsley, J.E., Carlson, B.E., Lin, J., Gao, X.: Accurate characterization of biaxial stress-strain response of sheet metal from bulge testing. Int. J. Plast 94, 192–213 (2017)

Hill, R. (1950). C. A theory of the plastic bulging of a metal diaphragm by lateral pressure. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 41(322), 1133–1142.

Xiang, Y., Chen, X., Vlassak, J.J.: Plane-strain bulge test for thin films. J. Mater. Res. 20(9), 2360–2370 (2005)

Vlassak, J.J., Nix, W.D.: A new bulge test technique for the determination of Young’s modulus and Poisson’s ratio of thin films. J. Mater. Res. 7(12), 3242–3249 (1992)

Lu, T., Chen, C., Zhao, K., Zhang, W., Wang, T.J.: Bulge test at nano-scale: the surface effects. Appl. Phys. Lett. 103(5), 053110 (2013)

Tinoco, H. A.; Holzer, J.; Pikálek, T.; Buchta, Z.; Lazar, J.; Alice, C.; Kruml, T.: Estimation of Mechanical Parameters of Thin Films Using Finite Element Analysis. In: Proceedings of 20th International Conference of applied Mechanics. Myslovice, Czech Republic. pp. 157–162 (2018). http://doi.org/https://doi.org/10.31224/osf.io/3adt5

Huang, C.K., Lou, W.M., Tsai, C.J., Wu, T.C., Lin, H.Y.: Mechanical properties of polymer thin film measured by the bulge test. Thin Solid Films 515(18), 7222–7226 (2007)

Timoshenko, S.P., Woinowsky-Krieger, S.: Theory of plates and shells. McGraw-hill, New York (1959)

Tabata, O. (1988). Internal stress and Young's modulus measurements of thin films using micromachining technology. In Technical Digest of the 7th Sensor Symposium (pp. 173–176).

Tabata, O., Kawahata, K., Sugiyama, S., Igarashi, I.: Mechanical property measurements of thin films using load-deflection of composite rectangular membranes. Sensors Actuat. 20(1–2), 135–141 (1989)

Wu, C. L., Fang, W., Yip, M. C.: Measurement of mechanical properties of thin films using bulge test. In: Soc. Exp. Mech. Proc (Vol. 22, no. 5) (2015).

Schalko, J., Beigelbeck, R., Stifter, M., Schneider, M., Bittner, A., Schmid, U.: Improved load-deflection method for the extraction of elasto-mechanical properties of circularly shaped thin-film diaphragms. In Smart Sensors, Actuators, and MEMS V (Vol. 8066, p. 80661J). International Society for Optics and Photonics (2011).

Zhang, J.J., Sun, Y.Y., Li, D.S., Cao, Y., Wang, Z., Ma, J., Zhao, G.Z.: Modeling the mechanics of graphene-based polymer composite film measured by the bulge test. J. Phys. D Appl. Phys. 48(42), 425302 (2015)

Shafqat, S., Van der Sluis, O., Geers, M., Hoefnagels, J.: A bulge test based methodology for characterizing ultra-thin buckled membranes. Thin Solid Films 660, 88–100 (2018)

Neggers, J., Hoefnagels, J.P., Geers, M.G.: On the validity regime of the bulge equations. J. Mater. Res. 27(9), 1245–1250 (2012)

Neggers, J., Hoefnagels, J.P.M., Hild, F., Roux, S., Geers, M.G.D.: A global digital image correlation enhanced full-field bulge test method. Proc. IUTAM 4, 73–81 (2012)

Maier-Schneider, D., Maibach, J., Obermeier, E.: A new analytical solution for the load-deflection of square membranes. J. Microelectromech. Syst. 4(4), 238–241 (1995)

Budiansky, B.: Notes on nonlinear shell theory. J. Appl. Mech. 35, 393–440 (1968)

Ventsel, T., Krauthammer, T.: Thin plates and shells: theory: analysis, and applications. CRC Press, Boca Raton (2001)

Pan, J.Y., Lin P., Maseeh, F., Senturia, S.D.: Verification of FEM analysis of load-deflection methods for measuring mechanical properties of thin films Tech. Digest IEEE Solid-State Sensor and Actuator Workshop (pp. 70–73) (1990).

Maier-Schneider, D., Köprülülü, A., Holm, S.B., Obermeier, E.: Elastic properties and microstructure of LPCVD polysilicon films. J. Micromech. Microeng. 6(4), 436 (1996)

Edwards, R.L., Coles, G., Sharpe, W.N.: Comparison of tensile and bulge tests for thin-film silicon nitride. Exp. Mech. 44(1), 49–54 (2004)

Xu, D., Liechti, K.M.: Bulge testing transparent thin films with moiré deflectometry. Exp. Mech. 50(2), 217–225 (2010)

Santos, A.D., Teixeira, P., Barata da Rocha, A., Barlat, F.: On the determination of flow stress using bulge test and mechanical measurement. In AIP Conference Proceedings (Vol. 1252, No. 1, pp. 845–852) (2010). AIP.

Ghanem, M., Göken, M., Merle, B.: Plane-strain bulge testing of thin films under compressive residual stresses. Surf. Coat. Technol. 327, 167–173 (2017)

Javed, H., Merle, B., Preiß, E., Hivet, R., Benedetto, A., Göken, M.: Mechanical characterization of metallic thin films by bulge and scratch testing. Surf. Coat. Technol. 289, 69–74 (2016)

Schweitzer, E.W., Göken, M.: In situ bulge testing in an atomic force microscope: Microdeformation experiments of thin film membranes. J. Mater. Res. 22(10), 2902–2911 (2007)

Overman, N.R., Overman, C.T., Zbib, H.M., Bahr, D.F.: Yield and deformation in biaxially stressed multilayer metallic thin films. J Eng. Mater. Technol. 10(1115/1), 3183775 (2009)

Youssef, H., Ferrand, A., Calmon, P., Pons, P., Plana, R.: Methods to improve reliability of bulge test technique to extract mechanical properties of thin films. Microelectron. Reliab. 50(9–11), 1888–1893 (2010)

Holzer, J., Pikálek, T., Buchta, Z., Lazar, J., Tinoco, H. A., Chlupová, A., Kruml, T.: (2017). Development of the bulge test equipment for measuring mechanical properties of thin films. In Proceedings of 26th International Conference on Metallurgy and Materials (pp. 1–6).

Orthner, M.P., Rieth, L.W., Solzbacher, F.: High speed wafer scale bulge testing for the determination of thin film mechanical properties. Rev. Sci. Instrum. 81(5), 055111 (2010)

Neggers, J., Hoefnagels, J.P.M., Hild, F., Roux, S., Geers, M.G.D.: Direct stress-strain measurements from bulged membranes using topography image correlation. Exp. Mech. 54(5), 717–727 (2014)

Ohring, M.: Materials science of thin films. Elsevier (2001)

Setter, N., Damjanovic, D., Eng, L., Fox, G., Gevorgian, S., Hong, S., et al.: Ferroelectric thin films: review of materials, properties, and applications. J. Appl. Phys. 100(5), 051606 (2006)

Mehregany, M., Tong, L., Matus, L.G., Larkin, D.J.: Internal stress and elastic modulus measurements on micromachined 3C-SiC thin films. IEEE Trans. Electron Devices 44(1), 74–79 (1997)

Shojaei, O.R., Karimi, A.: Comparison of mechanical properties of TiN thin films using nanoindentation and bulge test. Thin Solid Films 332(1–2), 202–208 (1998)

Acknowledgment

This research was supported by project TN01000071 of National Competence Centre of Mechatronics and Smart Technologies for Mechanical Engineering cofunded with the support of the Technology Agency of the Czech Republic, within the National Centres of Competence Programme.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

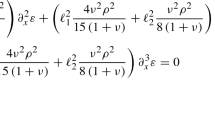

The strain functions depend on the rotations (first-order derivation) that are obtained as follows:

Also, the curvatures (second-order derivation) are computed for the \(x\)-direction:

and for the \(y\)-direction:

For the \(x - y\) plane, the mixed curvature is determined as:

To determine a set of kinematic equations in the x-direction, the derivatives should be evaluated at \(y = 0\) such that

Rights and permissions

About this article

Cite this article

Tinoco, H.A., Hutař, P., Kruml, T. et al. Modeling of elastoplastic behavior of freestanding square thin films under bulge testing. Acta Mech 232, 2715–2731 (2021). https://doi.org/10.1007/s00707-021-02978-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-02978-7