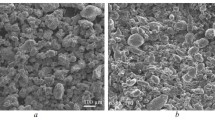

We study the influence of the conditions of impact compaction and heat treatment on the physicomechanical properties and structure of intermetallic compounds. We carried out the procedure of compaction by impact hot pressing of a Fe–14Al (wt.%) intermetallic compound prepared from iron and aluminum powders at temperatures of 1050 and 1150°C, as well as the procedure of annealing of compacted specimens at 1250°C for 60 min and at 1350 or 1450°C for 20 min. It is shown that the procedure of impact hot pressing makes it possible to obtain practically porousless specimens at temperatures of compaction equal to 1050°C and 1150°C. We managed to get high-quality contacts between intermetallic particles and to improve the mechanical properties as a result of annealing at a temperature of 1350°C.

Similar content being viewed by others

References

S. C. Deevi and V. K. Sikka, “Nickel and iron aluminides: An overview on properties, processing, and applications,” Intermetallics, 4, No. 5, 357–375 (1996).

J. Wang, J. Xing, Z. Qiu, X. Zhi, and L. Cao, “Effect of fabrication methods on microstructure and mechanical properties of Fe3Albased alloys,” J. Alloys Comp., 488, 117–122 (2009).

L. M. Peng, H. Li, J. H. Wang, and M. Gong, “High strength and high fracture toughness ceramic-iron aluminide (Fe3Al ) composites,” Mater. Lett., 60, 883–887 (2006).

M. Zamanzade, M. Barnoush, and C. Motz, “A review on the properties of iron aluminide intermetallics,” Crystals, 6, No. 1, 1–29 (2016).

N. S. Stoloff, “Iron aluminides: present status and future prospects,” Mater. Sci. Eng., Ser. A, 258, 1–14 (1998).

J. W. Cohron, Y. Lin, R. H. Zee, and E. P. George, “Room-temperature mechanical behavior of FeAl: Effects of stoichiometry, environment, and boron addition,” Acta Mater., 46, No. 17, 6245–6256 (1998).

C. Jia, Q. He, and J. Meng, “Fe3Al based alloys fabricated by spark plasma sintering from mechanically activated powders,” Mater. Sci. Forum, 539–543, 2706–2712 (2007).

C. Jia, Q. He, J. Meng, and L. Guo, “Influence of mechanical alloying time on the properties of Fe3Al intermetallics prepared by spark plasma sintering,” J. Univ. Sci. Technol. Beijing, 14, No. 4, 331–334 (2007).

H. Song, Y. Wu, C. Tang, S. Yuan, Q. Gong, and J. Liang, “Microstructure and mechanical properties of FeAl intermetallics prepared by mechanical alloying and hot-pressing,” Tsinghua Sci. Technol., 14, No. 3, 300–306 (2009).

H. А. Baglyuk, O. І. Tolochyn, О. V. Tolochyna, and R. V. Yakovenko, “Influence of the technological conditions of hot forging on the structure and properties of Fe3Al powder intermetallic compounds,” Visn. Nat. Techn. Univ. “KhPI,” Ser. Innov. Tekhnol. Obladn. Obrobky Mater. Mashyn. Metalurh., No. 44 (1087), 8–15 (2014).

G. A. Baglyuk, A. I. Tolochin, A. V. Tolochina, R. V. Yakovenko, A. N. Gripachevskii, and M. E. Golovkova, “Effect of process conditions on the structure and properties of the hot-forged Fe3Al intermetallic alloy,” Powder Metallurgy Metal Ceram., 55, No. 5–6, 297–305 (2016).

S. Szczepanik, E. Godlewska, and R. Mania, “Materiały Fe–Al otrzymane z proszków,” Kompozyty (Composites), 2, No. 4, 242–248 (2002).

S. Szczepanik, E. Godlewska, and R. Mania, “Influence of hot forming on the properties of Fe–Al intermetallic materials,” in: Proc. 8th Internat. Conf. on Metal Forming, Rotterdam (2000), pp. 477–484.

A. V. Laptev, “Potential of high-energy hot compaction in a vacuum for creating materials with an ultrafone structure and high strength,” Powder Metallurg. Met. Ceram., 40, No. 3–4, 103–111 (2001).

Yu. N. Podrezov, V. A. Nazarenko, A. V. Laptev, A. I. Tolochin, Ya. I. Evich, N. I. Danilenko, and O. M. Ivanova, “Structural dispersion of powder titanium in the optimal conditions of dynamic hot pressing,” Powder Metallurg. Met. Ceram., 51, No. 1–2, 56–63 (2012).

A. V. Laptev, A. I. Tolochin, M. S. Kovalchenko, Ya. I. Evich, and I. Yu. Okun’, “Structure and properties of Ni3Al intermetallic under vacuum impact sintering,” Powder Metallurg. Met. Ceram., 54, No. 9–10, 554–567 (2016).

N. P. Lyakishev, Diagrams of State for Binary Metallic Systems: A Handbook [in Russian], Vol. 1, Mashinostroenie, Moscow (1996).

S. Gedevanishvili and S. C. Deevi, “Processing of iron aluminides by pressureless sintering through Fe+Al elemental route,” Mater. Sci. Eng., Ser. A, 325, 163–176 (2002).

P. Novak, A. Michalcova, I. Marek, M. Mudrova, K. Saksl, J. Bednarcik, P. Zikmund, and D. Vojtech, “On the formation of intermetallics in Fe–Al system—An in-situ XDR study,” Intermetallics, 32, 127–136 (2013).

O. V. Mikhailov and M. B. Shtern, “Taking into account different resistances to tension and compression in the theories of plasticity of porous bodies,” Poroshk. Metallurg., No. 5, 17–23 (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 4, pp. 60–68, July–August, 2020.

Rights and permissions

About this article

Cite this article

Тоlochyn, О.І., Baglyuk, G.А., Tolochyna, O.V. et al. Structure and Physicomechanical Properties of the Fe3Al Intermetallic Compound Obtained by Impact Hot Compaction. Mater Sci 56, 499–508 (2021). https://doi.org/10.1007/s11003-021-00456-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00456-y