Abstract

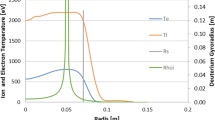

The interaction between graphite particles and argon plasma in the arc torch is investigated by numerical simulations. The addition of carbon vapor improves the specific heat capacity, electrical conductivity and thermal conductivity of plasma, and decreases its viscosity. It is important to note that the changes in the thermodynamic and transport properties of the plasma substantially affect the arc plasma temperature and the spatial distribution of the carbon vapor concentration. As the graphite particle feed rate increases, the arc will be continuously contracted and the arc electric current density will be increased. The carbon vapor enhances the plasma electrical conductivity, but the heat absorption by the particles reduces the temperature of the plasma, eventually leading to decreased the electrical conductivity. Both result in ascent of the electric field of the arc, so that increase the arc voltage. In addition, the heat flux radial distribution of radiation-absorption of the particles is much less than the thermal conduction, but the particles near the wall absorb radiation from arc region, so that reduce energy loss of the radiation of the arc column.

Similar content being viewed by others

Availability of Data and Material

All data and materials as well as software application support their published claims and comply with field standards.

Code Availability

Custom code support their published claims and comply with field standards.

References

Liu SH, Trelles JP, Murphy AB, Li L, Zhang SL, Yang GJ, Li CX, Li CJ (2019) J Phys D Appl Phys 52:335203

Chen J, Cheng Y (2009) J Chem Eng Jpn 42:s103–s110

Yugeswaran S, Selvarajan V, Seo D, Ogawa K (2008) Surf Coat Technol 203:129–136

Wan YP, Fincke JR, Sampath S, Prasad V, Herman H (2002) Int J Heat Mass Transf 45:1007–1015

Yang K, Rong J, Feng JW, Zhuang Y, Zhao HY, Wang L, Ni JX, Tao SY, Shao F, Ding CX (2017) Surf Coat Technol 326:96–102

Gulyaev I (2015) Ceram Int 41:101–107

Ye R, Proulx P, Boulos MI (2000) J Phys D Appl Phys 33:2154

Ye R, Ishigaki T, Jurewicz J, Proulx P, Boulos M (2004) Plasma Chem Plasma Process 24:555–571

Shigeta M, Watanabe T, Nishiyama H (2004) Thin Solid Films 457:192–200

http://www.mettech.com/coating-equipment/axial-III-plasma-spray-system.php

Ma J, Su BG, Wen GD, Yang QW, Ren QL, Yang YW, Xing HB (2017) Fuel Process Technol 167:721–729

Wang C, Cui HC, Li WW, Liao MR, Xia WL, Xia WD (2017) Chin Phys B 26:025202

Todorović-Marković B, Marković Z, Mohai I, Nikolić Z, Farkas Z, Szépvölgyi J, Kováts É, Scheier P, Feil S (2006) J Phys D Appl Phys 39:320

Wang C, Imahori T, Tanaka Y, Sakuta T, Takikawa H, Matsuo H (2001) Thin Solid Films 390:31–36

Szépvölgyi J, Marković Z, Todorović-Marković B, Nikolić Z, Mohai I, Farkas Z, Tóth M, Kováts É, Scheier P, Feil S (2006) Plasma Chem Plasma Process 26:597–608

Delbos C, Fazilleau J, Rat V, Coudert JF, Fauchais P, Pateyron B (2006) Plasma Chem Plasma Process 26:393–414

Saito H, Suzuki T, Fujino T, Suzuki M (2018) Mater Trans 59:1791–1797

Gawne D, Liu B, Bao Y, Zhang T (2005) Surf Coat Technol 191:242–254

Lee Y, Pfender E (1987) Plasma Chem Plasma Process 7:1–27

Mostaghimi-Tehrani J, Pfender E (1984) Plasma Chem Plasma Process 4:129–139

Chen X, Chyou Y, Lee YC, Pfender E (1985) Plasma Chem Plasma Process 5:119–141

Proulx P, Mostaghimi J, Boulos MI (1985) Int J Heat Mass Transfer 28:1327–1336

Suzuki T, Saito H, Fujino T (2018) IEEE T Plasma Sci 47:688–700

Bauchire J, Gonzalez J, Proulx P (1999) J Phys D Appl Phys 32:675

Proulx P, Mostaghimi J, Boulos MI (1987) Plasma Chem Plasma Process 7:29–52

Li HP, Chen X (2002) Plasma Chem Plasma Process 22:27–58

Xu DY, Wu XC, Chen X (2003) Surf Coat Technol 171:149–156

Pan ZH, Ye L, Qian SL, Sun Q, Wang C, Ye TH, Xia WD (2019) Plasma Sci Technol 22:025401

Wilke C (1950) J Chem Phys 18:517–519

ANSYS 2009 ANSYS FLUENT 12.0 Theory Guide (Canonsburg, PA)

Huang R, Fukanuma H, Uesugi Y, Tanaka Y (2012) J Therm Spray Technol 21:636–643

Han P, Chen X (2001) Plasma Chem Plasma Process 21:249–264

Bauchire J, Gonzalez J, Gleizes A (1997) Plasma Chem Plasma Process 17:409–432

Godin D, Trépanier J (2004) Plasma Chem Plasma Process 24:447–473

Wang WZ, Rong MZ, Murphy AB, Wu Y, Spencer JW, Yan JD, Fang MT (2011) J Phys D Appl Phys 44:355207

Pan WX, Meng X, Wu CK (2006) Plasma Sci Technol 8:416

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Nos. 11675177 and 11875256).

Funding

This work was supported by the National Natural Science Foundation of China (No. 11675177 and No. 11875256).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, Z., Chen, X., Yuan, X. et al. The Effects of Graphite Particles on arc Plasma Characteristics. Plasma Chem Plasma Process 41, 1183–1203 (2021). https://doi.org/10.1007/s11090-021-10177-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-021-10177-4