Abstract

Electronic waste can lead to the accumulation of environmentally and biologically toxic materials and is a growing global concern. Developments in transient electronics—in which devices are designed to disintegrate after use—have focused on increasing the biocompatibility, whereas efforts to develop methods to recapture and reuse materials have focused on conducting materials, while neglecting other electronic materials. Here, we report all-carbon thin-film transistors made using crystalline nanocellulose as a dielectric, carbon nanotubes as a semiconductor, graphene as a conductor and paper as a substrate. A crystalline nanocellulose ink is developed that is compatible with nanotube and graphene inks and can be written onto a paper substrate using room-temperature aerosol jet printing. The addition of mobile sodium ions to the dielectric improves the thin-film transistor on-current (87 μA mm−1) and subthreshold swing (132 mV dec−1), and leads to a faster voltage sweep rate (by around 20 times) than without ions. The devices also exhibit stable performance over six months in ambient conditions and can be controllably decomposed, with the graphene and carbon nanotube inks recaptured for recycling (>95% recapture efficiency) and reprinting of new transistors. We demonstrate the utility of the thin-film transistors by creating a fully printed, paper-based biosensor for lactate sensing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request.

References

Jambeck, J. et al. Plastic waste inputs from land into the ocean. Science 347, 768–771 (2015).

Hwang, S.-W. et al. A physically transient form of silicon electronics. Science 337, 1640–1644 (2012).

Boutry, C. M. et al. Biodegradable and flexible arterial-pulse sensor for the wireless monitoring of blood flow. Nat. Biomed. Eng. 3, 47–57 (2019).

Rüegg, M., Blum, R., Boero, G. & Brugger, J. Biodegradable frequency-selective magnesium radio-frequency microresonators for transient biomedical implants. Adv. Funct. Mater. 29, 1903051 (2019).

Tan, M. J. et al. Biodegradable electronics: cornerstone for sustainable electronics and transient applications. J. Mater. Chem. C 4, 5531–5558 (2016).

Teng, L. et al. Liquid metal-based transient circuits for flexible and recyclable electronics. Adv. Funct. Mater. 29, 1808739 (2019).

Liu, H., Li, J. & Tan, R. Flexible In2O3 nanowire transistors on paper substrates. IEEE J. Electron Devices Soc. 5, 141–144 (2017).

Irimia-Vladu, M. ‘Green’ electronics: biodegradable and biocompatible materials and devices for sustainable future. Chem. Soc. Rev. 43, 588–610 (2014).

Li, Y., Misra, M. & Gregori, S. Printing green nanomaterials for organic electronics. IEEE Trans. Compon. Packaging Manuf. Technol. 8, 1307–1315 (2018).

Banerjee, K. et al. Prospects of carbon nanomaterials for next-generation green electronics. In Proc. 10th IEEE Conference on Nanotechnology, NANO 2010 56–61 (IEEE, 2010); https://doi.org/10.1109/NANO.2010.5698053

Andrews, J. B. et al. Fully printed and flexible carbon nanotube transistors for pressure sensing in automobile tires. IEEE Sens. J. 18, 7875–7880 (2018).

Schroeder, V., Savagatrup, S., He, M., Lin, S. & Swager, T. M. Carbon nanotube chemical sensors. Chem. Rev. 119, 599–663 (2019).

Jesadabundit, W., Chaiyo, S., Siangproh, W. & Chailapakul, O. Simple and cost-effective electrochemical approach for monitoring of vitamin K in green vegetables. ChemElectroChem 7, 155–162 (2020).

Gaspar, D. et al. Nanocrystalline cellulose applied simultaneously as the gate dielectric and the substrate in flexible field effect transistors. Nanotechnology 25, 094008 (2014).

Petritz, A. et al. Cellulose as biodegradable high-k dielectric layer in organic complementary inverters. Appl. Phys. Lett. 103, 153303 (2013).

Xia, M., Cheng, Z., Han, J. & Zhang, S. Extremely stretchable all-carbon-nanotube transistor on flexible and transparent substrates. Appl. Phys. Lett. 105, 143504 (2014).

Zhang, Z., Zhang, M., Du, C., Li, L. & Chang, K. C. Improving performance of all-carbon-nanotube thin-film transistors by low temperature supercritical CO2 fluid activation. IEEE Electron Device Lett. 40, 921–924 (2019).

Li, B. et al. All-carbon electronic devices fabricated by directly grown single-walled carbon nanotubes on reduced graphene oxide electrodes. Adv. Mater. 22, 3058–3061 (2010).

Abdelmalik, A. A., Fothergill, J. C. & Dodd, S. J. Aging of Kraft paper insulation in natural ester dielectric fluid. In Proc. 2013 IEEE International Conference on Solid Dielectrics (ICSD) 541–544 (IEEE, 2013); https://doi.org/10.1109/ICSD.2013.6619678

Hamedi, M. M. et al. Highly conducting, strong nanocomposites based on nanocellulose-assisted aqueous dispersions of single-wall carbon nanotubes. ACS Nano 8, 2467–2476 (2014).

Parate, K. et al. Aerosol-jet-printed graphene electrochemical histamine sensors for food safety monitoring. 2D Mater. 7, 034002 (2020).

Jettable Fluid Formulation Guidelines (Fujifilm Dimatix, 2013).

McManus, D. et al. Water-based and biocompatible 2D crystal inks for all-inkjet-printed heterostructures. Nat. Nanotechnol. 12, 343–350 (2017).

McKerricher, G., Perez, J. G. & Shamim, A. Fully inkjet printed RF inductors and capacitors using polymer dielectric and silver conductive ink with through vias. IEEE Trans. Electron Devices 62, 1002–1009 (2015).

Pu, J. et al. Highly flexible MoS2 thin-film transistors with ion gel dielectrics. Nano Lett. 12, 4013–4017 (2012).

Cardenas, J. A. et al. Impact of morphology on printed contact performance in carbon nanotube thin-film transistors. Adv. Funct. Mater. 29, 1805727 (2019).

Higgins, T. M. et al. Electrolyte‐gated n‐type transistors produced from aqueous inks of WS2 nanosheets. Adv. Funct. Mater. 29, 1804387 (2018).

Chen, L. et al. Tailoring the yield and characteristics of wood cellulose nanocrystals (CNC) using concentrated acid hydrolysis. Cellulose 22, 1753–1762 (2015).

Zou, Z. et al. Rehealable, fully recyclable and malleable electronic skin enabled by dynamic covalent thermoset nanocomposite. Sci. Adv. 4, eaaq0508 (2018).

Martins, R. F. P. et al. Recyclable, flexible, low-power oxide electronics. Adv. Funct. Mater. 23, 2153–2161 (2013).

Williams, N. X. et al. Silver nanowire inks for direct-write electronic tattoo applications. Nanoscale 11, 14294–14302 (2019).

Lu, S. et al. Uniform and stable aerosol jet printing of carbon nanotube thin-film transistors by ink temperature control. ACS Appl. Mater. Interfaces 12, 43083–43089 (2020).

Moberg, T. et al. Rheological properties of nanocellulose suspensions: effects of fibril/particle dimensions and surface characteristics. Cellulose 24, 2499–2510 (2017).

Phan-Xuan, T. et al. Aggregation behavior of aqueous cellulose nanocrystals: the effect of inorganic salts. Cellulose 23, 3653–3663 (2016).

Wu, Q., Li, X., Fu, S., Li, Q. & Wang, S. Estimation of aspect ratio of cellulose nanocrystals by viscosity measurement: influence of surface charge density and NaCl concentration. Cellulose 24, 3255–3264 (2017).

Acknowledgements

This work was performed in part at the Duke University Shared Materials Instrumentation Facility (SMIF), a member of the North Carolina Research Triangle Nanotechnology Network (RTNN), which is supported by the National Science Foundation (grant no. ECCS-1542015) as part of the National Nanotechnology Coordinated Infrastructure (NNCI). This work was supported by the Department of Defense Congressionally Directed Medical Research Program (CDMRP) under award no. W81XWH-17-2-0045 and by the National Institutes of Health (NIH) under award no. 1R01HL146849. G.B. and M.J.T. are grateful to the Air Force Office of Scientific Research for research support under award no. FA9550-18-1-0222.

Author information

Authors and Affiliations

Contributions

N.X.W. and A.D.F. conceived the idea for the project, designed the experiments and analysed the data. N.X.W. performed ink development, printing, device design and characterization experiments. G.B. and M.J.T. performed and analysed recycling experiments. N.B. performed and analysed lactate sensor experiments. N.X.W. and A.D.F. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Electronics thanks Seungjun Chung and Kamrul Hassan for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Viscometric properties of inks.

a, Dynamic Viscosities of all inks as a function of shear rates. b, Strain dependent storage (G’, blue line) and loss (G”, red) moduli, measured at a frequency of 1 Hz, for nanocellulose ink (first column), graphene ink (second column), silver nanowire ink (third column) and carbon nanotube ink (fourth column). c, Frequency dependent storage (G’, blue line) and loss (G”, red) moduli. It should be noted that the viscosities of the AgNW and the CNT inks are approaching the measurement limits of the rheometer.

Extended Data Fig. 2 Characterization of printed inks.

a, Heights of single pass nanocellulose thin-films printed onto a paper substrate (top) and silicon substrate (bottom). Boxed region represents printed thin-film area. The height of the CNC thin-film is most likely lower on the paper substrate due to impregnation of the nanocellulose film into the fibrous paper. b, Heights of graphene thin-films printed onto a paper substrate (top) and silicon substrate (bottom). Boxed region represents printed thin-film area. No graphene height can be observed on the paper substrate due to wicking of the ink into the paper substrate. c, Printed line widths (left) for nanocellulose lines printed onto paper substrates (blue) and silicon substrates (red) as a function of print passes. Box represents lower and upper quartile range, line represents median, and whiskers represent lowest and highest value. Line widths represent 10 width measurements from 1 print. Printed line roughness values (right) for nanocellulose lines. Datapoints represent average and standard deviation of 5 profilometry measurements taken from 1 print. d, Graphene line widths (left) and roughness values (right) for printed lines on paper substrates (blue) and silicon substrates (red).

Extended Data Fig. 3 Crystalline Nanocellulose dielectric characterization.

a, Top-view optical image and (b) SEM cross-sectional image of nanocellulose parallel plate capacitor. c, Capacitance as a function of frequency for nanocellulose capacitor before heating (dashed line) and after heating to 80 °C for 1 hour (solid blue lines) measured every 30 seconds for 30 minutes (light to dark blue), indicating strong frequency dependence of capacitance and a recoverable decay of low-frequency capacitance after heating. d, Capacitance response to atmosphere conditions in vacuum (blue), air (white), and nitrogen (grey). Both tests demonstrate hydration dependence on capacitance with a decrease in low-frequency capacitance after water evaporation due to heat and vacuum, respectively. The nitrogen atmosphere demonstrates that the capacitance decrease is caused by a hydration decrease as opposed to an environmental pressure change.

Extended Data Fig. 4 Crystalline nanocellulose capacitance-charge relationship.

Nanocellulose capacitance as a function of frequency measured on parallel plate capacitors for nanocellulose dielectric films printed with 6% w/w crystalline nanocellulose in DI water (blue), 6% desulfonated crystalline nanocellulose in DI water (red), 6% crystalline nanocellulose in ultrapure water (green), and 6% desulfonated crystalline nanocellulose in ultrapure water (purple). This illustrates that the intrinsic ionic nature of the nanocellulose dielectric is derived from the dissolved salts in addition to the sulfonation from the hydrolysis of cellulose. Data represent average ± standard deviation of 4 devices.

Extended Data Fig. 5 Nanocellulose-based all-carbon TFT electrical characterization.

a, Subthreshold curves at varying drain-sourcevoltages (Vds) demonstrating the optimization of on/off-current ratio at a Vds of -0.5 V. b) Output curves at varying gate voltages. A clear shift in conduction pathway can be seen at increasingly positive Vgs where carriers are now tunneling through the Schottky barrier into the conduction band rather than the lower-barrier injection of carriers into the valence band at negative gate bias. The transistors were fabricated with a 0.15 mM salt concentration in crystalline nanocellulose and tested with a sweep frequency of 10 ms.

Extended Data Fig. 6 All-carbon TFT back-to-back cycling without added salt in nanocellulose dielectric.

a, Transfer curves (drain current plotted on a linear scale against gate voltage) and (b) corresponding gate leakage currents demonstrating a 15% decrease in on-current and a 77% decrease in leakage current over 9 cycles, attributed to limitations in ion mobility and a time delay in the development of a double layer in the nanocellulose dielectric. c, Transfer curves for two back-to-back cycles showing a marked decrease in hysteresis between the (black) first and (red) second cycles and a significant (~2x) increase in on-current, attributed to the slow formation of the double layer charge that guides the decrease in gate leakage. Without the addition of salt, the transistor behavior is highly dependent on device history, both in terms of cycle duration (hold time) and in terms of cycle number. The transistor was fabricated without added salt and tested with a sweep rate of ~mV s-1 .

Extended Data Fig. 7 Viscosity of crystalline nanocellulose ink with added mobile ions.

Dynamic viscosity of 6% crystalline nanocellulose solutions with increasing salt concentrations demonstrating the electroviscous effect.

Extended Data Fig. 8 Lactate biosensing from fully printed all-carbon devices on paper.

a, Schematic of (top) 2-electrode and (bottom) transistor-based, all-carbon lactate sensors. Electronic lactate concentration testing using (b) the 2-electrode sensor and (c) the transistor-based sensor. d, Transistor-based testing setup. e, Current dependence on lactate concentration showing a more pronounced current response to increases in lactate concentration with the 2-electrode device; however, a current maximum is reached at a concentration that is too small for medical relevance whereas the transistor-based device extends the sensing window by at least 5x, allowing for medically relevant lactate sensing. Lactate concentrations greater than 2 mM in human blood are indicative of septic shock. Furthermore, recent research indicates that mortality rates for patients presenting with elevated lactate concentrations was highly dependent on the duration of sepsis. Mortality sharply declined when lactate levels stabilized to a value of 2.2 mM as opposed to those that maintained a concentration of 3.3 mM after 4 hours. Hence, the 2-electrode sensor, which has a higher sensitivity than the transistor-based sensor (5.16 μA mM−1 vs 0.37 μA mM−1, respectively) has a sensing window that is too narrow for complete medical relevance. Working electrode area is 5 mm2 for all measurements).

Extended Data Fig. 9 Nanomaterial ink recycling yield.

a, New CNT ink (blue) and 5x recycling iterations of CNT ink (red—dark→light; recycling cycles 1→5). The difference in baseline absorbance (away from the CNT peaks) between inks at ostensibly the same concentration may be due to some particulate matter left in the ink. b, To allow for CNT concentration measurement, the baselines were aligned and plotted and the area under the curve from a wavelength of 800–1200 nm was measured. The percent yield (insert) was measured by subtracting the integrands (that is Recycling round 1: % yield = \({\int}_{800}^{1200} {Recycle\,round} 1 - {\int}_{800}^{1200} {New\,ink}\)). c, New (blue) and 5x recycling iterations of graphene ink (red—dark→light; recycling cycles 1→5). With the graphene ink the baseline absorbance (away from the graphene peak) is markedly higher for the new ink, potentially due to the added viscosifiers. b, baseline corrected graphene ink absorbance with recycling yield (insert). Graphene ink integration was measured from 200—800 nm.

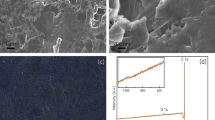

Extended Data Fig. 10 CNT printing density.

SEM images of CNT thin films printed on silicon using (a) pristine and (b) recycled CNT ink for purposes of determining printed density (45% and 36% coverage for new and recycled inks, respectively). c,d, For analysis, each image was set to binary using ImageJ, and in addition, in e,f, the color threshold was modified to help guide the eye. The decrease in printed ink density may help explain the slightly lower on-current with the recycled CNT ink.

Supplementary information

Supplementary Information

Supplementary Fig. 1 and Table 1.

Rights and permissions

About this article

Cite this article

Williams, N.X., Bullard, G., Brooke, N. et al. Printable and recyclable carbon electronics using crystalline nanocellulose dielectrics. Nat Electron 4, 261–268 (2021). https://doi.org/10.1038/s41928-021-00574-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-021-00574-0

This article is cited by

-

Aerosol jet printing of surface acoustic wave microfluidic devices

Microsystems & Nanoengineering (2024)

-

Organic flexible electronics with closed-loop recycling for sustainable wearable technology

Nature Electronics (2023)

-

Making electronics that don’t last

Nature Electronics (2022)

-

Wirelessly powered large-area electronics for the Internet of Things

Nature Electronics (2022)

-

Room-temperature high-precision printing of flexible wireless electronics based on MXene inks

Nature Communications (2022)