Abstract

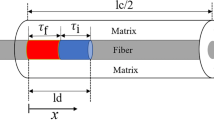

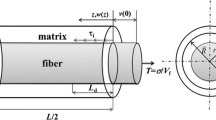

An approach to simulate the constitutive model of a unidirectionally SiC fiber-reinforced titanium matrix composite during spectrum loading was developed in this paper. Based on the assumption that there is a microcrack in the matrix and the maximum shear stress criterion, the debonding length and the distribution of interfacial slip zone under spectrum loading were derived. The stress at a loading point was divided into four stages including crack opening section, positive slip zone, reverse slip zone, and bond zone. Based on the partial crack shear-lag model, the stress of fiber and matrix in the four stages was derived, and the constitutive model of the composite under spectrum loading was established. At last, the effects of different damages on the constitutive model and interfacial debonding zone of a unidirectionally SiC fiber-reinforced titanium matrix composite were investigated.

Similar content being viewed by others

Data Availability

All date used to support the findings of this study are included within the article.

References

Hayat, M.D., Singh, H., He, Z., Cao, P.: Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 121, 418–438 (2019)

Shirvanimoghaddam, K., Hamim, S.U., Karbalaei Akbari, M., Fakhrhoseini, S.M., Khayyam, H., Pakseresht, A.H., Ghasali, E., Zabet, M., Munir, K.S., Jia, S., Davim, J.P., Naebe, M.: Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part A Appl. Sci. Manuf. 92, 70–96 (2017)

Lino Alves, F.J., Baptista, A.M., Marques, A.T.: 3 - Metal and ceramic matrix composites in aerospace engineering. Presented at the (2016)

Wang, P.C., Jeng, S.M., Yang, J.M.: Characterization and modeling of stiffness reduction in SCS-6-Ti composites under low cycle fatigue loading. Mater. Sci. Eng. A. 200, 173–180 (1995)

China Aeronautical Materials Manual Committee. China Aeronautical Materials Manual. 3. Aluminum alloy, magnesium alloy and titanium alloy, (1989)

Sun, Z., Sun, J., Chang, Y., Sun, W., Qi, L., Song, Y.: Axial Tensile Failure Analysis of SiCf/Ti Composite Based on Continuum Cohesive Zone Model. J. Mater. Eng. Perform. 28, 956–966 (2019)

Hassanzadeh-Aghdam, M., Edalatpanah, S.A., Azaripour, S.: Interphase region effect on the biaxial yielding envelope of SiC fiber-reinforced Ti matrix composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 233, 095440621877753 (2018).

Lou, J.H., Yang, Y.Q., Luo, X., Yuan, M.N., Feng, G.H.: The analysis on transverse tensile behavior of SiC/Ti–6Al–4V composites by finite element method. Mater. Des. 31, 3949–3953 (2010)

Totry, E., González, C., LLorca, J.: Failure locus of fiber-reinforced composites under transverse compression and out-of-plane shear. Compos. Sci. Technol. 68, 829–839 (2008)

Yanfang, X., Tiexiong, S., Meini, Y.: Study of Interfacial Stress Distribution in SiC Fiber Reinforced Titanium Matrix Composites on Transverse Tensile Tests. J. Mater. Eng. Perform. 21, 2446–2450 (2012)

Mahmoodi, M.J., Aghdam, M.M.: Damage analysis of fiber reinforced Ti-alloy subjected to multi-axial loading—A micromechanical approach. Mater. Sci. Eng. A. 528, 7983–7990 (2011)

Aghdam, M.M., Falahatgar, S.R., Gorji, M.: Micromechanical consideration of interface damage in fiber reinforced Ti-alloy under various combined loading conditions. Compos. Sci. Technol. 68, 3406–3411 (2008)

Zhang, F., Niu, X., Chen, X., Sun, Z., Song, Y.: Simulation of tension-compression hysteresis loop of an unidirectionally SiC fiber-reinforced titanium matrix composite. Compos. Interfaces. 27, 795–813 (2020)

Guanghai, F., Yanqing, Y., Jian, L., Xian, L., Bin, H., Qing, S., Chen, W., Yan, C.: Fatigue Behavior and Damage Evolution of SiC Fiberreinforced Ti-6Al-4V Alloy Matrix Composites. Rare Met. Mater. Eng. 43, 2049–2054 (2014)

Bettge, D., Günther, B., Wedell, W., Portella, P.D., Hemptenmacher, J., Peters, P.W.M., Skrotzki, B.: Mechanical behavior and fatigue damage of a titanium matrix composite reinforced with continuous SiC fibers. Mater. Sci. Eng. A. 452–453, 536–544 (2007)

Wang, P.C., Jeng, S.M., Yang, J.M., Mal, A.K.: Fatigue life prediction of fiber-reinforced titanium matrix composites. Acta Mater. 44, 1097–1108 (1996)

Boyum, E.A., Mall, S.: Fatigue behavior of a cross-ply titanium matrix composite under tension-tension and tension-compression cycling. Mater. Sci. Eng. A. 200, 1–11 (1995)

Jeng, S.M., Alassoeur, P., Yang, J.-M.: Fracture mechanisms of fiber-reinforced titanium alloy matrix composites V: Fatigue crack propagation. Mater. Sci. Eng. A. 154, 11–19 (1992)

Kong, X., Wang, Y., Yang, Q., Zhang, X., Zhang, G., Yang, L., Wu, Y., Yang, R.: Low-cycle fatigue behavior and damage progression of a fiber reinforced titanium matrix composite. Int. J. Light. Mater. Manuf. 4, (2020)

Sun, W., Sun, Z., Lu, Q., Chen, X., Song, Y.: Fatigue Hysteresis Loops Simulation of SiCf /Ti Composites under Two-Stage Cyclic Loading. Appl. Compos. Mater. 26, 1041–1057 (2019)

Yang, J.-M., Jeng, S.M., Yang, C.J.: Fracture mechanisms of fiber-reinforced titanium alloy matrix composites Part I: Interfacial behavior. Mater. Sci. Eng. A. 138, 155–167 (1991)

Cox, H.L.: The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 3, 72–79 (1952)

Budiansky, B., Hutchinson, J.W., Evans, A.G.: Matrix fracture in fiber-reinforced ceramics. J. Mech. Phys. Solids. 34, 167–189 (1986)

Kuo, W., Chou, T.: Multiple Cracking of Unidirectional and Cross-PlyCeramic Matrix Composites. J. Am. Ceram. Soc. 78, (1995)

Her, Y.C., Wang, P.C., Yang, J.M.: Fatigue crack initiation and multiplication of unnotched titanium matrix composites, (1998)

Shojiro, O., Okumura, I., Tanaka, M., Hojo, M., Inoue, T.: Influences of residual stresses, frictional shear stress at debonded interface and interactions among broken components on interfacial debonding in unidirectional multi-filamentary composites. Compos. Interfaces - Compos INTERFACE. 5, 363–381 (1997)

Mahesh, S., Mishra, A.: Strength distribution of Ti/SiC metal-matrix composites under monotonic loading. Eng. Fract. Mech. 194, 86–104 (2018)

Gao, X., Fang, G., Song, Y.: Hysteresis loop model of unidirectional carbon fiber-reinforced ceramic matrix composites under an arbitrary cyclic load. Compos. Part B Eng. 56, 92–99 (2014)

Solti, J.P., Robertson, D.D., Mall, S.: Estimation of interfacial properties from hysteretic energy loss in unidirectional ceramic matrix composites. Adv. Compos. Mater. 9, 161–173 (2000)

Li, L.: Fatigue damage model and life prediction of long-fiber- reinforced ceramic matrix composites. Nanjing University of Aeronautics and Astronautics;Chinese, Nanjing(CN) (2010)

Acknowledgments

This work was supported by the National Basic Research Program of China, the National Natural Science Foundation of China [grant number 51675266]; the Postgraduate Research & Practice Innovation Program of Jiangsu Province [grant number KYCX18_0314]; the Fundamental Research Funds for the Central Universities [grant number NJ20160038]; the Jiangsu Province Key Laboratory of Aerospace Power System [grant number CEPE2019004] are gratefully acknowledged; and the Jiang Planned Projects for Postdoctoral Research Funds [grant number 2019K029].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Sun, Z., Niu, X. et al. The Constitutive Model of a Unidirectional SiC Fiber-Reinforced Titanium Matrix Composite During Spectrum Loading. Appl Compos Mater 28, 1019–1037 (2021). https://doi.org/10.1007/s10443-021-09881-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09881-3